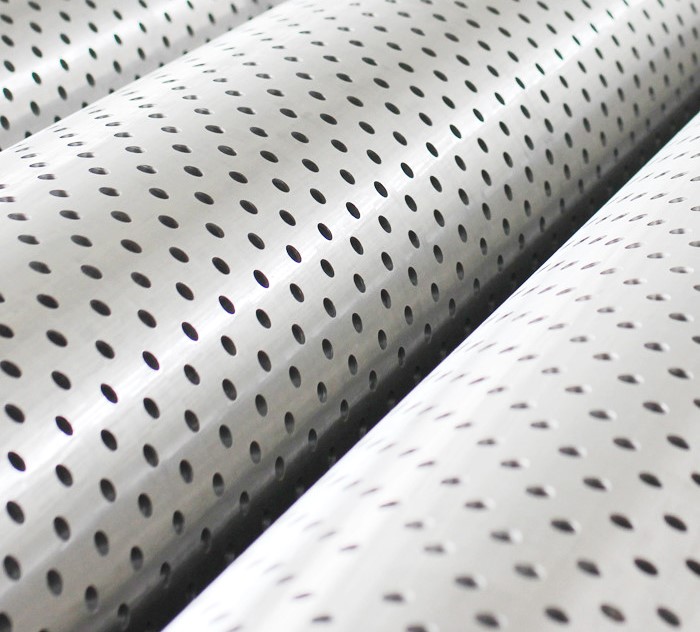

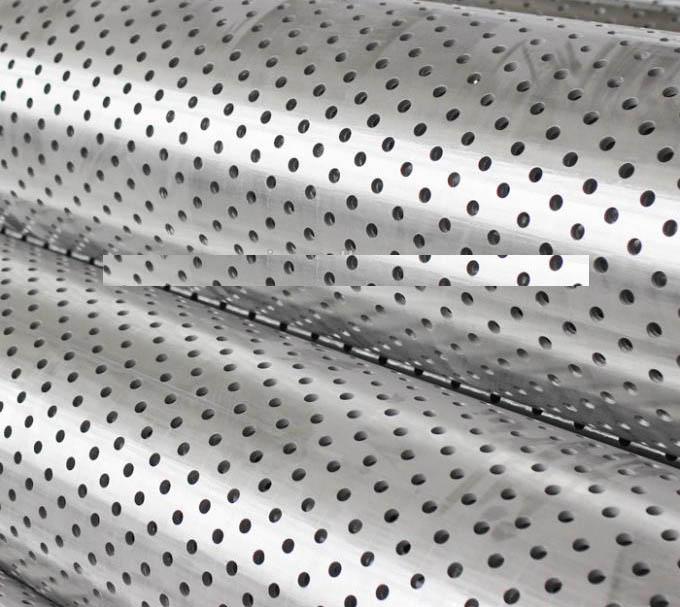

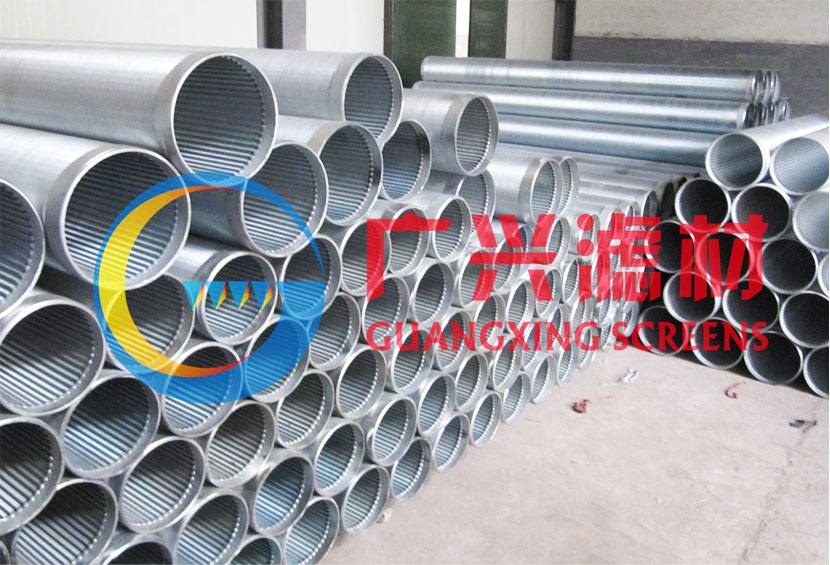

Perforated Stainless Steel Filter Pipe

February 21, 2024

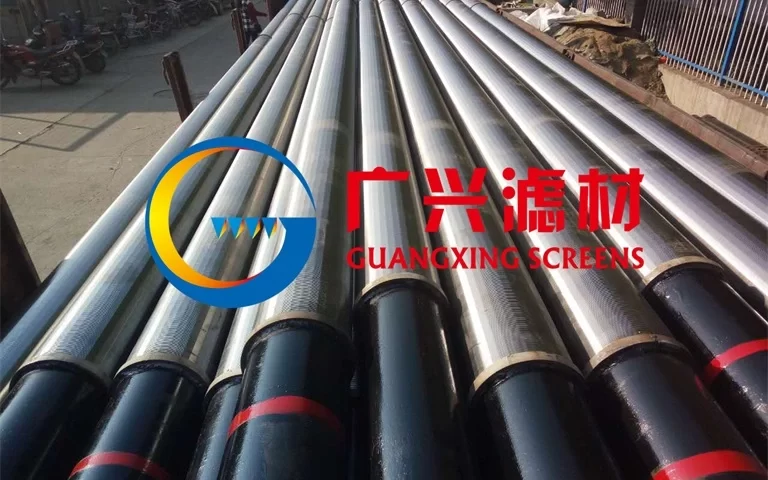

Water Well Screen Pipe | Stainless steel

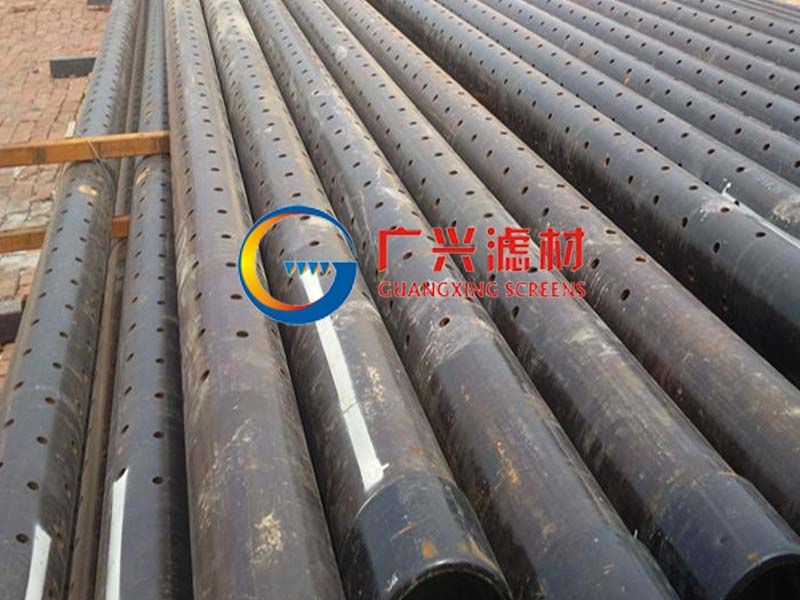

July 2, 2024The round OD 5 1/2″ laser slotted well screen with N80 material base pipe is a specialized casing pipe designed for sand control and optimal well performance in the oil and gas industry. This particular well screen is constructed with a base pipe made of N80 material, which is a type of corrosion-resistant alloy known for its durability and strength in challenging downhole environments.

The laser slotting technology used in this well screen ensures precise and uniform slots along the length of the pipe. These laser-cut slots are strategically placed to allow for controlled inflow of reservoir fluids while effectively blocking the entry of sand and other formation particles. The use of laser technology ensures accurate slot dimensions and smooth edges, minimizing the risk of plugging and improving overall well productivity.

The round OD 5 1/2″ size of this well screen makes it suitable for a range of well applications. It can be used in both open-hole and cased-hole completions, providing flexibility in well design and installation. The 5 1/2″ diameter is a common size used in many well operations and allows for efficient fluid flow while maintaining sand control capabilities.

The N80 material base pipe offers excellent corrosion resistance, making it well-suited for harsh downhole conditions. It can withstand the corrosive effects of fluids and gases encountered in oil and gas reservoirs, ensuring the longevity and integrity of the well screen. The N80 material also provides the necessary strength and structural support required for well operations.

The installation process of the round OD 5 1/2″ laser slotted well screen with N80 material base pipe is similar to other casing pipes. It is run into the wellbore and cemented in place to provide stability and isolation. The laser-cut slots are positioned based on reservoir characteristics and production objectives, ensuring optimal sand control and inflow performance.

In summary, the round OD 5 1/2″ laser slotted well screen with N80 material base pipe is a high-quality casing pipe designed for sand control and well performance optimization. With its precise laser-cut slots, N80 material base pipe, and versatile size, this well screen offers reliable sand control capabilities, durability, and flexibility in various well applications.

Product performance:

1. Our slotted liner use J55/K55/N80 casing and tubings of API standard, with High overall strength, not so easy to deformation.

2. The edge of the slot is vertical, smooth, without burrs, and the slot is uniformity.

3. The perforated pipe is suitable for sandy well, which the diameter of the sand greater than 0.3mm.

4. The slot can be longitudinal and transverse, the section of the slot can be parallel and trapezoidal types, with a wide open area.

| API Std.Casing | ID

(mm) |

Length

(mm) |

Slot Length

(mm) |

Slot No./m | Slot Width

(mm) |

Slot Tolerance | Valid Filter Area

(cm2/m) |

Max.

Strength (kn) |

||

| Spec.

(mm) |

Thickness

(mm) |

Per Weight (mm) |

||||||||

| 60.32 | 5 | 6.84 | 50.3 | 3 | 80 | 200 | 0.3 | ±50 | 48 | 512.54 |

| 73.02 | 5.5 | 9.15 | 62 | 3 | 80 | 240 | 0.3 | ±50 | 57.6 | 688.55 |

| 88.9 | 6.5 | 13.22 | 75.9 | 3 | 80 | 280 | 0.3 | ±50 | 67.2 | 995.1 |

| 101.6 | 6.5 | 15.22 | 88.6 | 3 | 80 | 300 | 0.3 | ±50 | 72 | 1151.2 |

| 114.3 | 7 | 18.47 | 100.3 | 10 | 80 | 320 | 0.3 | ±50 | 76.8 | 1400.4 |

| 127 | 7.52 | 22.13 | 112 | 10 | 80 | 340 | 0.3 | ±50 | 81.6 | 1673.8 |

| 139.7 | 7.72 | 25.11 | 124.3 | 10 | 80 | 360 | 0.3 | ±50 | 86.4 | 1900.2 |

| 9.17 | 29.48 | 121.4 | 10 | 80 | 360 | 0.3 | ±50 | 86.4 | 2232.4 | |

| 168.3 | 8.94 | 35.09 | 150.4 | 10 | 80 | 400 | 0.3 | ±50 | 96 | 2672.95 |

| 177.8 | 8.05 | 33.68 | 161.7 | 10 | 80 | 440 | 0.3 | ±50 | 105.6 | 2559.2 |

| 9.19 | 38.19 | 159.4 | 10 | 80 | 440 | 0.3 | ±50 | 105.6 | 2940.7 | |

Superior Alloy Attributes

Grade N80 composition imbues max strength retention even in harshest HC environments:

- 9% nickel content withstands temperatures up to 400°F where carbon steels degrade.

- Minimum 80,000psi yield strength maintains bore integrity deeper/hotter than other alloys.

- Uniform carbide precipitation through precise thermo-mechanical processing maximizes wear resistance to proppants/sands long-term.

These inherent defenses against downhole threats safeguard productivity over multi-decade durations like no other material.

The process of laser cutting a slotted liner involves several important steps to ensure the quality and performance of the pipe. Let’s explore the procedure in detail:

1. Surface Treatment:

Before the slotting process begins, the pipe undergoes surface treatment to prepare it for laser cutting. This treatment involves cleaning the pipe surface to remove any dirt, debris, or contaminants that could affect the quality of the slots. Additionally, any rust or oxide layers are removed to ensure a clean and smooth surface for the laser cutting process.

2. Cooling and Heat Elimination:

During the slotting process, the laser generates heat as it cuts through the pipe material. To prevent overheating and potential damage to the pipe, cooling mechanisms are employed. This can include the use of coolants or water jets to dissipate the heat and maintain a controlled temperature. Proper heat elimination is crucial to maintain the structural integrity of the pipe and prevent any distortions or deformations.

3. Quality Inspection:

After the slotting process is complete, each pipe undergoes a thorough quality inspection. This inspection ensures that the slots are cut to the specified dimensions and meet the required standards. Any substandard pipes that do not meet the quality criteria are identified and separated for proper disposal or recycling.

4. Marking and Certification:

Pipes that pass the quality inspection are marked to indicate that they meet the required specifications. This marking can include information such as the slot dimensions, pipe material, manufacturing date, and any other relevant details. Additionally, a material certificate is issued for each pipe, providing documentation of the pipe’s quality and compliance with industry standards.

5. Delivery of Goods:

Once the quality inspection and marking processes are complete, the pipes are ready for delivery to the intended destination. Proper packaging and handling procedures are followed to ensure the pipes are protected during transportation and arrive in optimal condition.

By following these steps, the laser cutting of slotted liners can be carried out efficiently and effectively. The careful control of machining parameters, surface treatment, cooling, quality inspection, marking, and certification ensures that the resulting slotted liners meet the required standards and provide reliable sand control capabilities in well applications.

In conclusion, the process of laser cutting slotted liners involves surface treatment, cooling, quality inspection, marking, and certification to ensure the highest quality and performance of the pipes. These steps are crucial in achieving well-designed slots that meet the required specifications and provide effective sand control in various well applications.