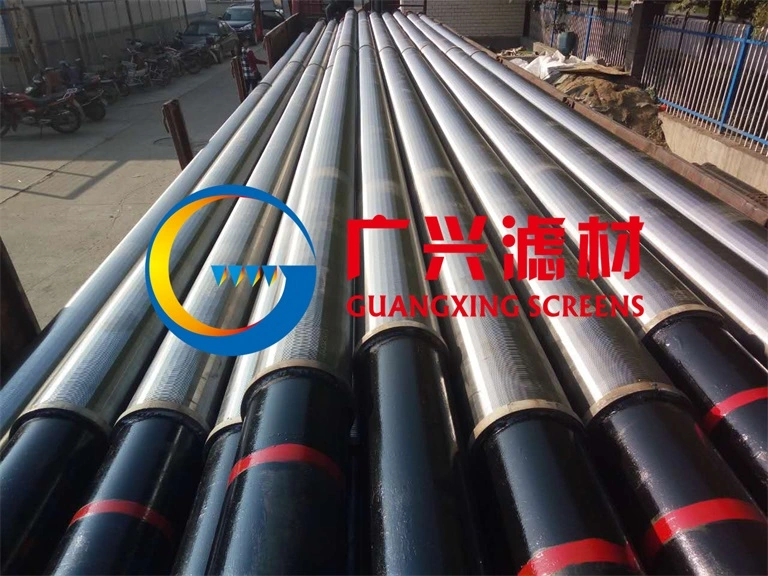

Oil Water Well Screen Filter: The Ultimate Solution for Water, Oil, and Gas Filtration

February 6, 2024

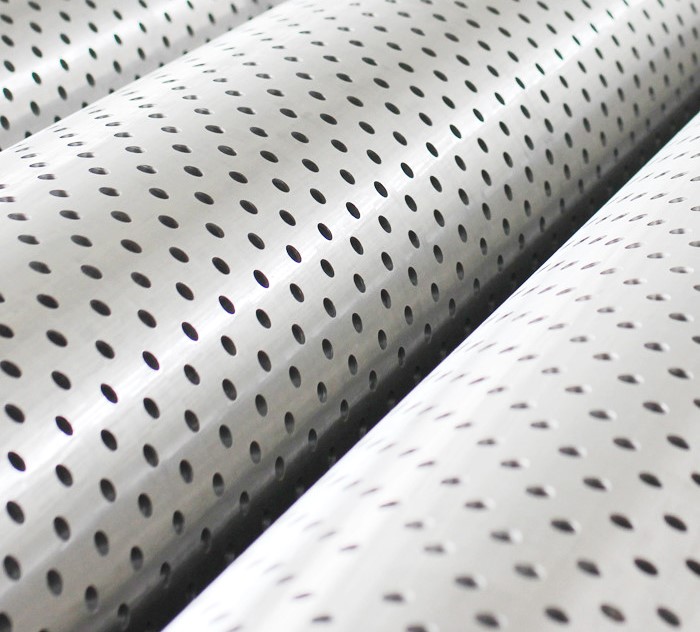

Perforated Stainless Steel Filter Pipe

February 21, 2024Thank you for providing the specifications of the API 5CT Standard K55 Perforated Stainless Steel Pipe Screen. This information further highlights the technical details and capabilities of the product. Let’s delve deeper into the applications, benefits, and frequently asked questions regarding the API 5CT K55 Perforated Steel Pipe.

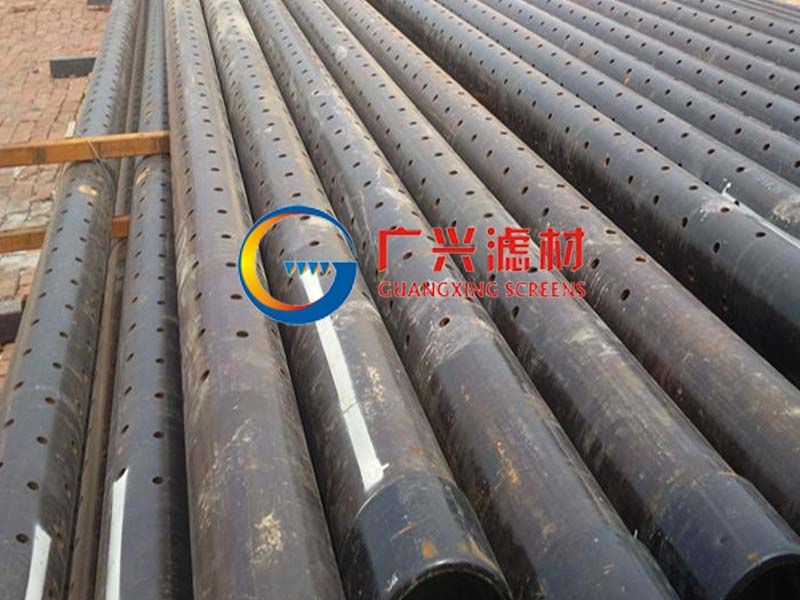

Applications of API 5CT K55 Perforated Steel Pipe

The API 5CT K55 Perforated Steel Pipe finds its application in various areas of the oil and gas industry. Some of the key applications include:

- Filtration: The perforated design of the pipe allows for the controlled flow of fluids while filtering out unwanted particles and debris. It is commonly used in filtration systems to ensure the purity and quality of the extracted oil or gas.

- Well Completion: The API 5CT K55 Perforated Steel Pipe is an essential component in well completion operations. It helps in maintaining the integrity of the wellbore, preventing sand and other formation materials from entering the well, and facilitating the efficient production of oil and gas.

- Sand Control: Sand production is a common challenge in oil and gas wells. The perforated steel pipe acts as a sand control mechanism by allowing the flow of hydrocarbons while preventing the entry of sand and other solid particles. This helps in maintaining well productivity and prolonging the life of the well.

- Reservoir Monitoring: Perforated steel pipes are also used in reservoir monitoring systems. They allow for the installation of sensors and gauges to monitor the pressure, temperature, and fluid levels in the reservoir. This data is crucial for optimizing production and reservoir management.

Benefits of API 5CT K55 Perforated Steel Pipe

The API 5CT K55 Perforated Steel Pipe offers several benefits that make it a preferred choice in the oil and gas industry. Some of the key benefits include:

- Enhanced Flow Control: The precision perforations in the pipe allow for precise control of fluid flow, ensuring optimal production rates and minimizing pressure drops. This leads to improved efficiency and performance of the well.

- Improved Wellbore Stability: The API 5CT K55 Perforated Steel Pipe helps in maintaining the stability of the wellbore by preventing the influx of formation materials. This reduces the risk of wellbore collapse and ensures safe and reliable operations.

- Extended Well Life: By preventing sand production and minimizing formation damage, the perforated steel pipe helps in extending the life of the well. This translates to increased productivity, reduced maintenance costs, and enhanced profitability.

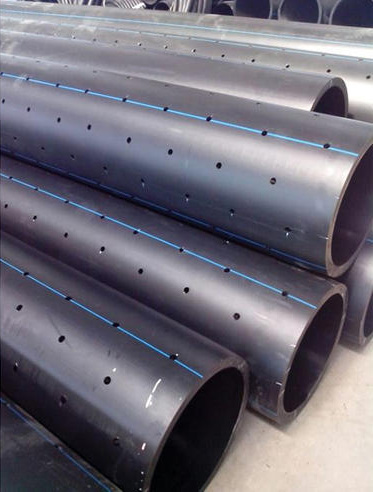

- Versatility: The API 5CT K55 Perforated Steel Pipe can be customized to meet specific project requirements. It is available in various sizes, hole patterns, and open areas, allowing for flexibility in design and application.

- Cost-Effective: The durability and longevity of the API 5CT K55 Perforated Steel Pipe result in cost savings over the lifetime of the well. Its resistance to corrosion and mechanical stresses reduces the need for frequent replacements and repairs.

Frequently Asked Questions (FAQ)

Q1: What is the difference between API 5CT K55 and J55?

A1: API 5CT K55 and J55 are both steel grades specified by the American Petroleum Institute. The main difference lies in their yield strength. K55 has a higher yield strength than J55, making it more suitable for demanding applications.

Q2: Can the API 5CT K55 Perforated Steel Pipe be used in offshore drilling operations?

A2: Yes, the API 5CT K55 Perforated Steel Pipe is suitable for both onshore and offshore drilling operations. Its high strength and corrosion-resistant properties make it well-suited for the harsh offshore environment.

Q3: How is the open area of the perforated steel pipe determined?

A3: The open area of the perforated steel pipe is calculated by dividing the total area of the perforations by the total area of the pipe. It is expressed as a percentage.

Q4: Can the API 5CT K55 Perforated Steel Pipe be customized to specific hole sizes and patterns?

A4: Yes, the API 5CT K55 Perforated Steel Pipe can be customized to meet specific hole sizes and patterns. This allows for precise control of fluid flow and filtration requirements.

Q5: What are the available lengths of the API 5CT K55 Perforated Steel Pipe?

A5: The API 5CT K55 Perforated Steel Pipe is available in various lengths, with R3 being a common length used in oil and gas operations. Other lengths can be customized as per project requirements.

For more information about the API 5CT K55 Perforated Steel Pipe and its applications, please visit [OASIS] you for providing the specifications of the API 5CT Standard K55 Perforated Stainless Steel Pipe Screen. This information further highlights the technical details and capabilities of the product. Let’s delve deeper into the applications, benefits, and frequently asked questions regarding the API 5CT K55 Perforated Steel Pipe.

Applications of API 5CT K55 Perforated Steel Pipe

The API 5CT K55 Perforated Steel Pipe finds its application in various areas of the oil and gas industry. Some of the key applications include:

- Filtration: The perforated design of the pipe allows for the controlled flow of fluids while filtering out unwanted particles and debris. It is commonly used in filtration systems to ensure the purity and quality of the extracted oil or gas.

- Well Completion: The API 5CT K55 Perforated Steel Pipe is an essential component in well completion operations. It helps in maintaining the integrity of the wellbore, preventing sand and other formation materials from entering the well, and facilitating the efficient production of oil and gas.

- Sand Control: Sand production is a common challenge in oil and gas wells. The perforated steel pipe acts as a sand control mechanism by allowing the flow of hydrocarbons while preventing the entry of sand and other solid particles. This helps in maintaining well productivity and prolonging the life of the well.

- Reservoir Monitoring: Perforated steel pipes are also used in reservoir monitoring systems. They allow for the installation of sensors and gauges to monitor the pressure, temperature, and fluid levels in the reservoir. This data is crucial for optimizing production and reservoir management.

Benefits of API 5CT K55 Perforated Steel Pipe

The API 5CT K55 Perforated Steel Pipe offers several benefits that make it a preferred choice in the oil and gas industry. Some of the key benefits include:

- Enhanced Flow Control: The precision perforations in the pipe allow for precise control of fluid flow, ensuring optimal production rates and minimizing pressure drops. This leads to improved efficiency and performance of the well.

- Improved Wellbore Stability: The API 5CT K55 Perforated Steel Pipe helps in maintaining the stability of the wellbore by preventing the influx of formation materials. This reduces the risk of wellbore collapse and ensures safe and reliable operations.

- Extended Well Life: By preventing sand production and minimizing formation damage, the perforated steel pipe helps in extending the life of the well. This translates to increased productivity, reduced maintenance costs, and enhanced profitability.

- Versatility: The API 5CT K55 Perforated Steel Pipe can be customized to meet specific project requirements. It is available in various sizes, hole patterns, and open areas, allowing for flexibility in design and application.

- Cost-Effective: The durability and longevity of the API 5CT K55 Perforated Steel Pipe result in cost savings over the lifetime of the well. Its resistance to corrosion and mechanical stresses reduces the need for frequent replacements and repairs.

Frequently Asked Questions (FAQ)

Q1: What is the difference between API 5CT K55 and J55?

A1: API 5CT K55 and J55 are both steel grades specified by the American Petroleum Institute. The main difference lies in their yield strength. K55 has a higher yield strength than J55, making it more suitable for demanding applications.

Q2: Can the API 5CT K55 Perforated Steel Pipe be used in offshore drilling operations?

A2: Yes, the API 5CT K55 Perforated Steel Pipe is suitable for both onshore and offshore drilling operations. Its high strength and corrosion-resistant properties make it well-suited for the harsh offshore environment.

Q3: How is the open area of the perforated steel pipe determined?

A3: The open area of the perforated steel pipe is calculated by dividing the total area of the perforations by the total area of the pipe. It is expressed as a percentage.

Q4: Can the API 5CT K55 Perforated Steel Pipe be customized to specific hole sizes and patterns?

A4: Yes, the API 5CT K55 Perforated Steel Pipe can be customized to meet specific hole sizes and patterns. This allows for precise control of fluid flow and filtration requirements.

Q5: What are the available lengths of the API 5CT K55 Perforated Steel Pipe?

A5: The API 5CT K55 Perforated Steel Pipe is available in various lengths, with R3 being a common length used in oil and gas operations. Other lengths can be customized as per project requirements.

For more information about the API 5CT K55 Perforated Steel Pipe and its applications, please visit [OASIS]