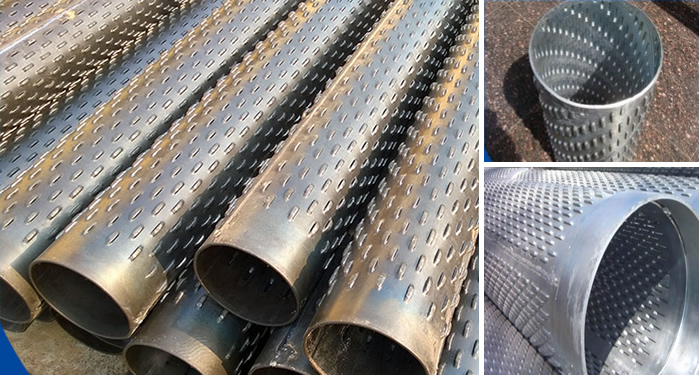

Mill Sloted Screen,Wire Wrap Screen & Bridge Slot well screen: What’s the difference

May 27, 2023

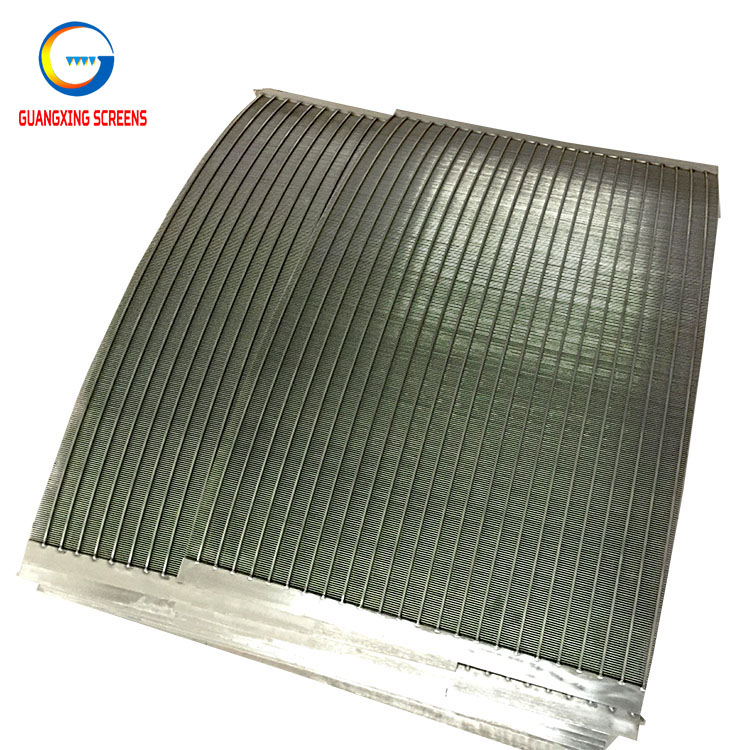

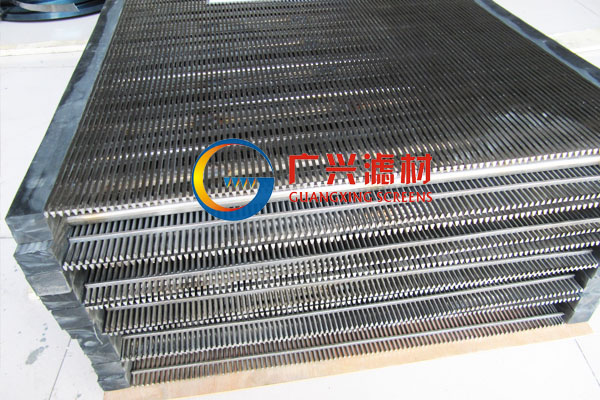

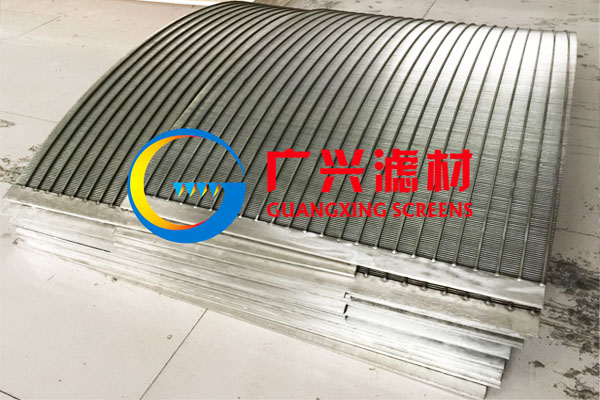

Johnson type well screen support grating

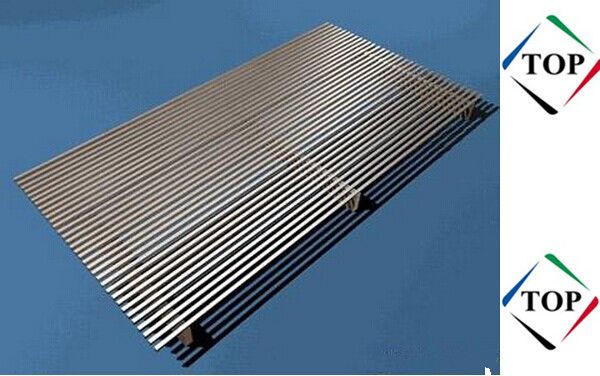

June 19, 2023Separator screens come in several sizes ranging from 5′ X 6′ to 8′ X 12′. The appropriate size is selected based on the type of waste being separated and rate processing requirements; we will find the perfect combination to process your waste water and manure efficiently and economically. Our v-wire screens come with a wide range of opening spacing, 0.010” to 0.060”. Moisture contents of 85% are attainable for separated solids with a separator screen alone.

Our waste water and manure screen separator are not only useful at dairies, they perform in a variety of situations and waste materials.

Wedge wire screens are a type of filtration device commonly used in various industries for solid-liquid separation, liquid-gas separation, and particle classification. When used in a looped screen separator, the screens are designed to filter out contaminants from the process stream, providing a clean output product.

A looped screen separator typically consists of the following components:

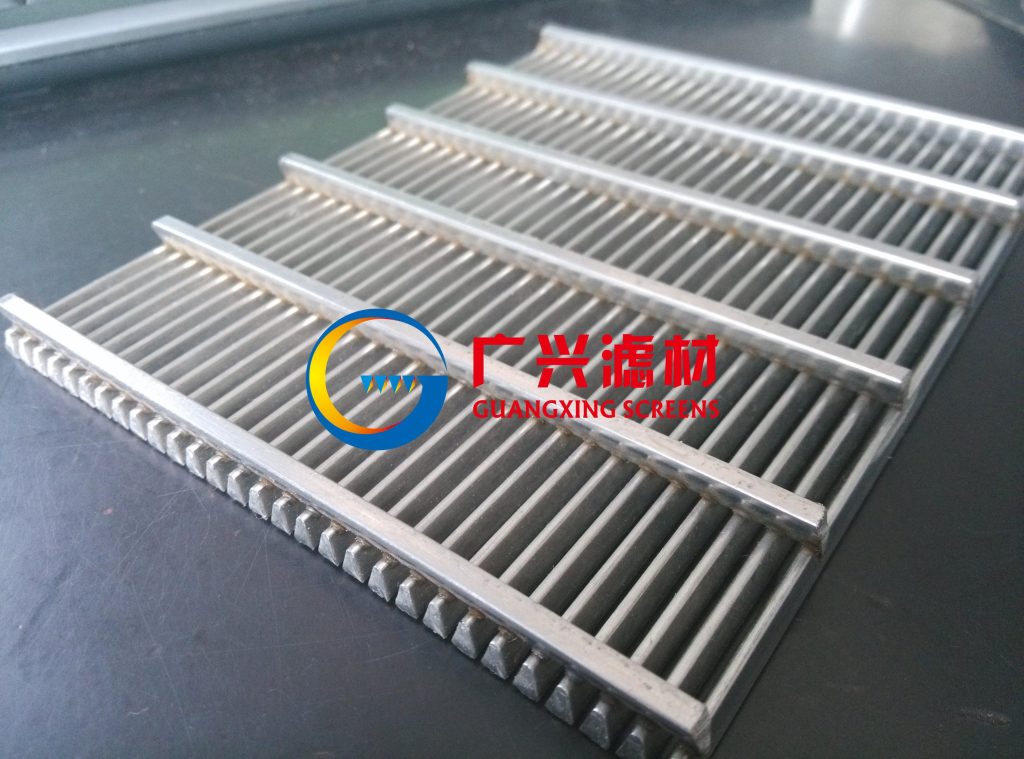

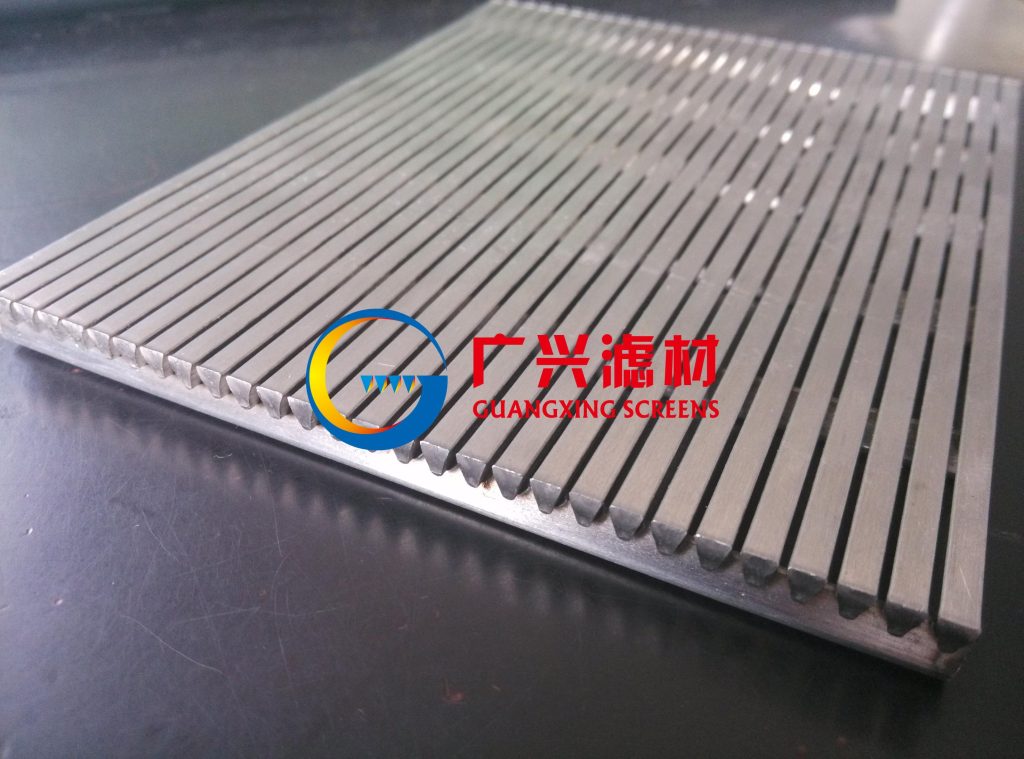

Wedge wire screen: Made from stainless steel, wedge wire screens have a unique V-shaped wire profile that provides high open area and non-clogging filtration properties. The screens are constructed by wrapping the V-shaped wire around supporting rods, which are welded together at each intersection. The gap between the wires (slot size) can be customized according to the separation requirements.

Housing: The looped screen separator housing encloses the wedge wire screen and helps to direct process flow through the unit. It typically includes inlet and outlet connections for easy integration into the process pipeline.

Support structure: A sturdy support structure holds the wedge wire screen in place within the housing and ensures the screen maintains its shape during operation.

Drive mechanism: Some looped screen separators feature a drive mechanism, such as a motor or a geared system, to rotate or vibrate the screen. This movement helps to prevent the build-up of particles on the screen surface and promotes efficient filtration.

Looped screen separators with wedge wire screens are used in various applications, including:

Water and wastewater treatment

Food and beverage processing

Pharmaceutical manufacturing

Petrochemical and refining industries

Pulp and paper processing

Mining and mineral processing

The benefits of using wedge wire screens in looped screen separators include:

High filtration efficiency due to their non-clogging design

Customizable slot sizes for precise separation requirements

Resistance to corrosion and abrasion, resulting in a longer service life

Easy maintenance and cleaning due to their self-cleaning properties

Environmentally friendly as they can be reused and recycled