API 5CT K55 Perforated Steel Pipe

February 6, 2024

N80 Laser Slotted Well Screen Pipe

March 15, 2024Perforated Stainless Steel Filter Pipe

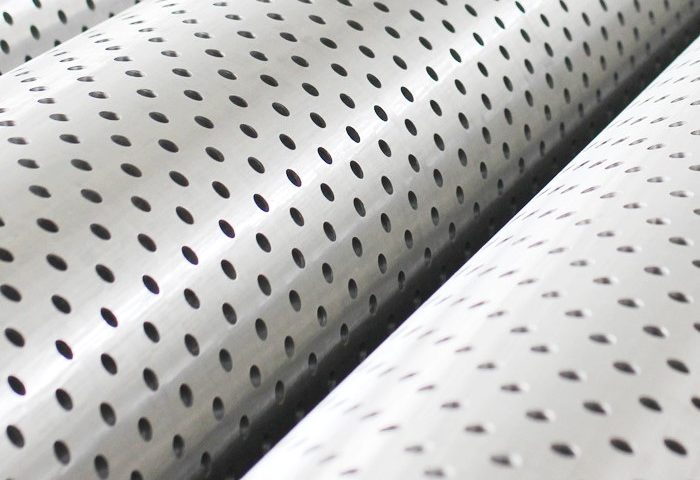

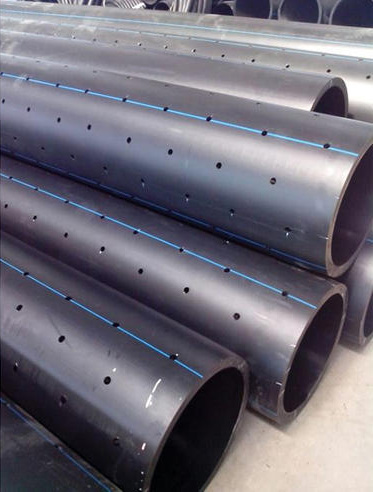

Perforated stainless steel filter pipes are a versatile solution used in various applications, particularly in the oil and gas industry. These pipes are designed to allow the flow of fluids while preventing the passage of unwanted particles such as sand or rock bits. In this article, we will explore the features, benefits, and technical parameters of perforated stainless steel filter pipes.

I. Features of Perforated Stainless Steel Filter Pipe

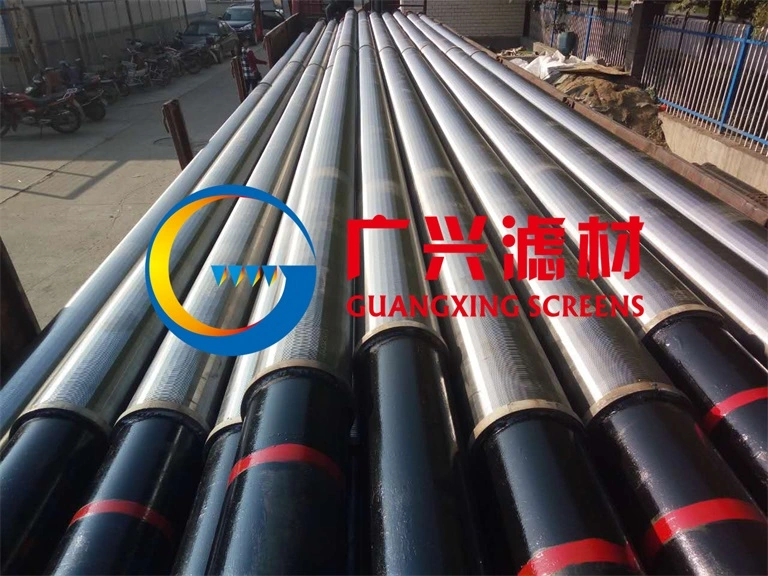

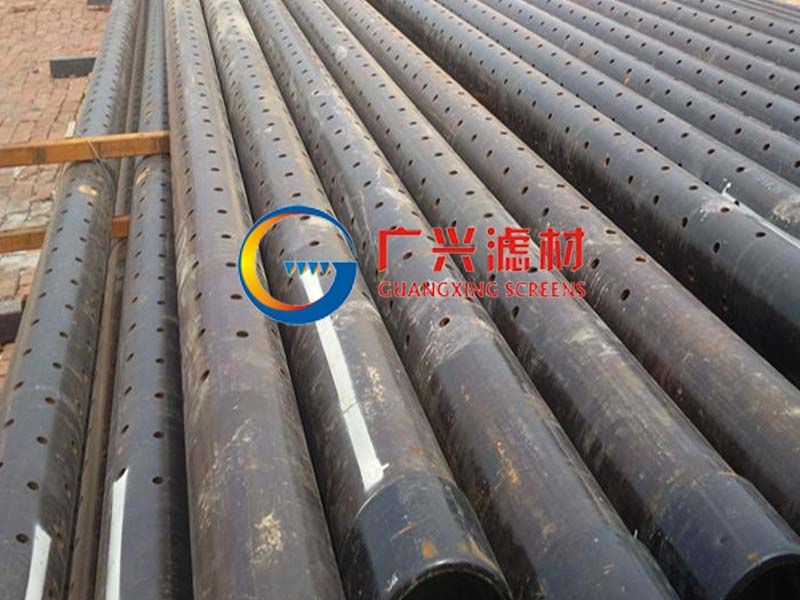

- High Strength: Perforated pipes are made from J55/K55/N80 casing and tubings of API standard, ensuring high overall strength and resistance to deformation.

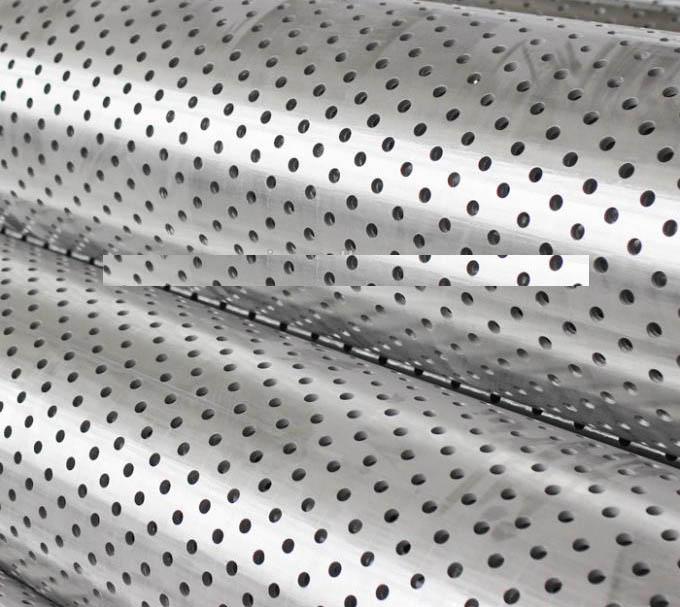

- Uniform and Smooth Holes: The holes in the perforated pipe are uniform and smooth, without any burrs. This ensures consistent flow and prevents clogging.

- Anticorrosion Treatment: The entire pipe undergoes an anticorrosion treatment, forming a protective covering. This treatment enhances the pipe’s resistance to corrosion and abrasion, prolonging its working life underground.

- Ease of Operation: Perforated stainless steel filter pipes are easy to operate and convenient to use, making them suitable for various applications.

- Customizable Hole Size and Pattern: The hole size and number in the perforated pipe can be custom designed to meet specific requirements. This flexibility allows for optimal filtration and flow control.

II. Applications of Perforated Stainless Steel Filter Pipe

Perforated stainless steel filter pipes find extensive use in the oil and gas industry, particularly in the following applications:

- Oil Reservation Layer: These pipes are used in oil wells where there is minimal sand or to prevent rock bits from dropping off the well bore. They help maintain the integrity of the well and ensure efficient oil extraction.

- Horizontal Oil Wells: Perforated pipes are specially designed for use in horizontal oil wells. They facilitate the flow of oil and gas while preventing the ingress of unwanted particles.

- Sand Rock and Carbonate Oil Reservation: These pipes are suitable for applications involving sand rock and carbonate oil reservation. They effectively filter out unwanted particles, ensuring the quality and purity of the extracted oil.

III. Technical Parameters of Stainless Steel Round Hole Perforated Pipe

The technical parameters of perforated stainless steel filter pipes vary based on the pipe size and hole specifications. Here are some examples:

| Pipe Size (inch) | Holes per (feet) | Size of Hole (inch) | Perforated Area per feet |

|---|---|---|---|

| 3/4” | 78 | 3/16” | 2.15 |

| 1” | 54 | 5/16” | 4.14 |

| 2-7/8” | 102 | 3/8” | 11.26 |

| 6-5/8” | 186 | 3/8” | 20.53 |

| 9-5/8” | 294 | 3/8” | 32.46 |

These parameters provide an overview of the hole sizes, hole numbers, and perforated areas for different pipe sizes. However, it’s important to note that these parameters can be customized according to specific project requirements.

IV. Conclusion

Perforated stainless steel filter pipes are essential components in the oil and gas industry, offering reliable filtration and flow control solutions. Their high strength, uniform hole distribution, and anticorrosion properties make them ideal for various applications, including oil reservation, horizontal oil wells, and sand rock and carbonate oil reservation. With the ability to customize hole sizes and patterns, these pipes provide flexibility and efficiency in fluid management.

When selecting perforated stainless steel filter pipes, it is crucial to consider the specific requirements of the project and consult with industry professionals to ensure optimal performance and longevity.

Note: This article is for informational purposes only and does not constitute professional advice. Always consult with experts in the field for specific recommendations and guidelines.