johnson Wedge Wire Screen Filter Mesh, Stainless Steel, deep well strainer pipe

December 31, 2016

Wedge Wire Slot Well Screens for Water Well Drilling

January 16, 2017

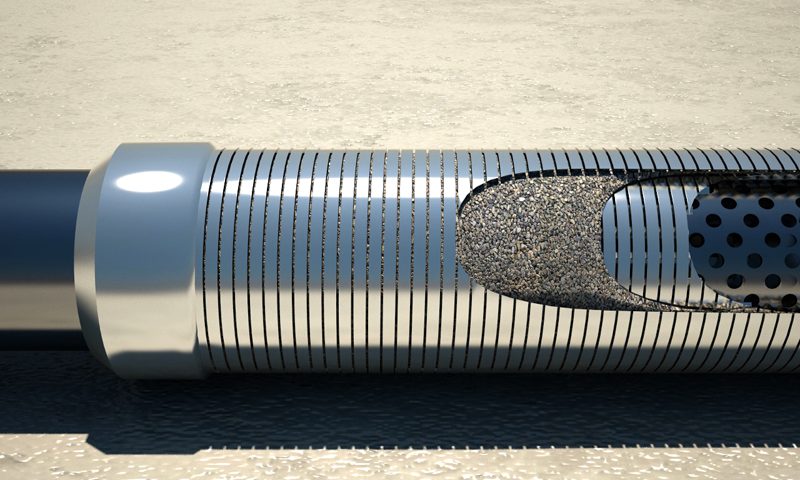

Pre-Pack Well Screen Systems

STAINLESS wire wrapped Continuous Slot Pre-pack/prepacked Well Screen

The pre-packed screens consists of perforated pipe, outer jacket ,end ring and centralizer. Key-stone or house shape wires are simultaneously wrapped and welded to form uniform slots. The jacket is then placed over perforated pipe and welded to each end. The LIDA pre-packed screens ’s strength, high quality and precise slot control make it an excellent choice for deep, vertical wells as well as horizontal wells.

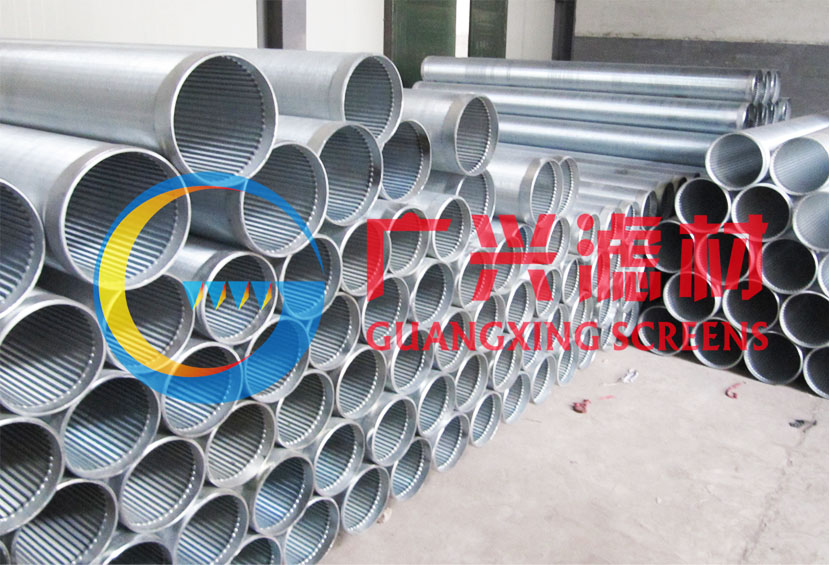

GUANGXING:

GUANGXING:

The GuangXing is a pre-packed screen providing sand control when conventional gravel packing is not feasible or economical. They are commonly used gas wells and gas storages and in cased or open-hole horizontal wells and also at the top of high pressure gravel pack completions. The GuangXing screen is designed for reduced OD/ID ratio running operations.

Pre-packed screen is equipped with packed layer itself. This unique configuration eliminates gravel placement and significantly shorten the time of drilling a well.

Horizontal gravel pack

Prepacked screens are commonly used in cased or open-hole horizontal wells and also at the top of high pressure gravel pack completions.

The GuangXing screen is designed for reduced OD/ID ratio running operations.

| Base Pipe | Gravel Pack | Perforations | Screen | ||||||

| OD

On.) |

ID

(in.) |

Weight

(lbs.) |

Coupling OD (in.) | Thickness

(in〇 |

Size

(in.) |

Holes/ft. | OD

(in.) |

Cylinder Area (sq in./ft) | .006 GA Inlet Area (sq in./ft) |

| 1.9 | 1.61 | 2.75 | 2.2 | 0.144 | 3/8 | 84 | 2.72 | 102.49 | 6.46 |

| 2.063 | 1.75 | 3.25 | 2.5 | 0.144 | 3/8 | 84 | 2.883 | 108.63 | 6.84 |

| 2.375 | 1.99 | 4.6 | 2.875 | 0.144 | 3/8 | 96 | 3.195 | 120.39 | 7.58 |

| 2.875 | 2.44 | 6.4 | 3.5 | 0.144 | 3/8 | 108 | 3.695 | 139.23 | 8.77 |

| 3.5 | 2.99 | 9.2 | 4.25 | 0.144 | 3/8 | 132 | 4.32 | 162.78 | 10.26 |

| 4 | 3.55 | 9.5 | 4.5 | 0.144 | 3/8 | 144 | 4.82 | 181.62 | 11.44 |

| 4.5 | 4 | 11.6 | 5 | 0.144 | 3/8 | 156 | 5.32 | 200.46 | 12.63 |

| 5 | 4.41 | 15 | 5.563 | 0.144 | 3/8 | 168 | 5.82 | 219.3 | 13.82 |

Available in oil and gas well completions, especially in an open or cased hole with unconsolidated formations where stand-alone screen is needed.

Uniform compacted and bonded

The minimum 0,12” thin filter media pack is created with the highest quality re-sieved, resin coated gravel, compacted with a unique vibrating system and heat treated to secure a consistent bond. Un-like conventional prepacked screens the thermal curing process is temperature controlled and monitored over time in a special furnace. The result is uniform compacted and bonded prepacked screen free of any voids.

Features

The GuangXing Screen design ensures:

- Complete gravel packing around the screen in horizontal wells.

- Bonded uniform gravel pack without bridges or voids.

- Reduced OD maximizes base pipe size.

- Smaller borehole compared to gravel packing

- Economical alternative to cased-hole gravel packs.

- Closer contact with the aquifer improving development and efficiency

Customized design

The design is customized to your demands.

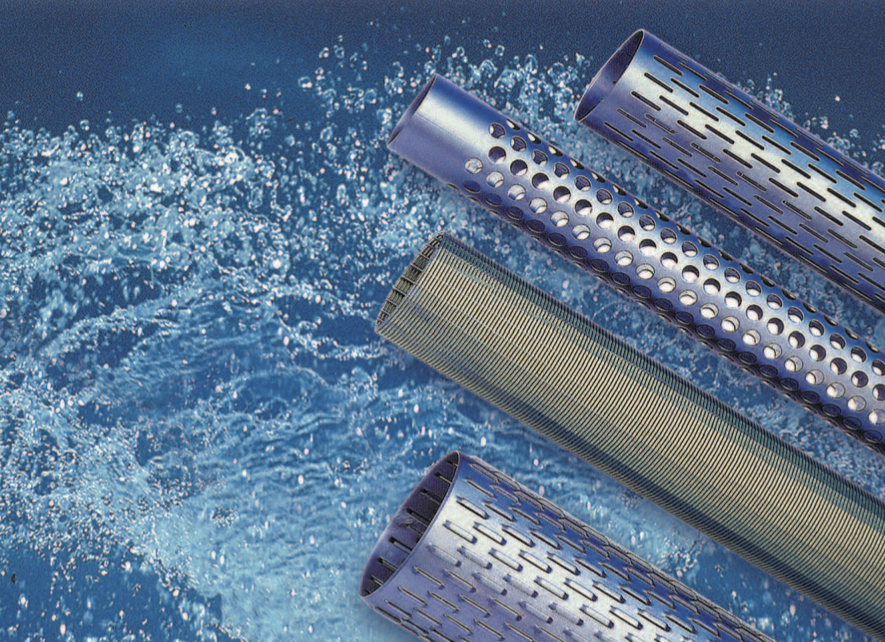

- Customizing sizes:Stainless Steel Casing – casings are available in sizes from 1″ Pipe Size – 12″ Pipe Size, lengths to 20′, and schedules 5, 10, and 40.

- Stainless Steel Screens – are available in lengths to 40′, slot sizes from 0.006″ – 0.250″, for setting in any depth, and in sizes from 1/2″ – 36″ in pipe (PS)* and telescope (T)** sizes.

- All API and ANSI pipe sizes are available

- Customized construction:

- Lower V-wires for reduced OD

- Protection by an outer shroud possible

- Customized material grades :GuangXing Products offers a complete line of stainless steel well screens, casings, and fittings in a wide range of sizes, lengths, and styles for use in water and environmental wells where performance and longevity are of the utmost importance. stainless steel 304, 316L, carbon steel and special alloys like Monel or as required depending on practical applications . Stainless steel material gives it ability of resisting erosion. Screens, casings, and fittings are available in 304, 304L, 316, and 316L stainless steel.

- Customized end-fittings and threaded connections

- Fixation of screen by welding or shrink fitting of end-rings to the base-pipe