What is wedge wire filter?

What is wedge wire screen used for?

What size is wedge wire filter?

What is the advantage of wedge filter?

Wedge Wire Filter

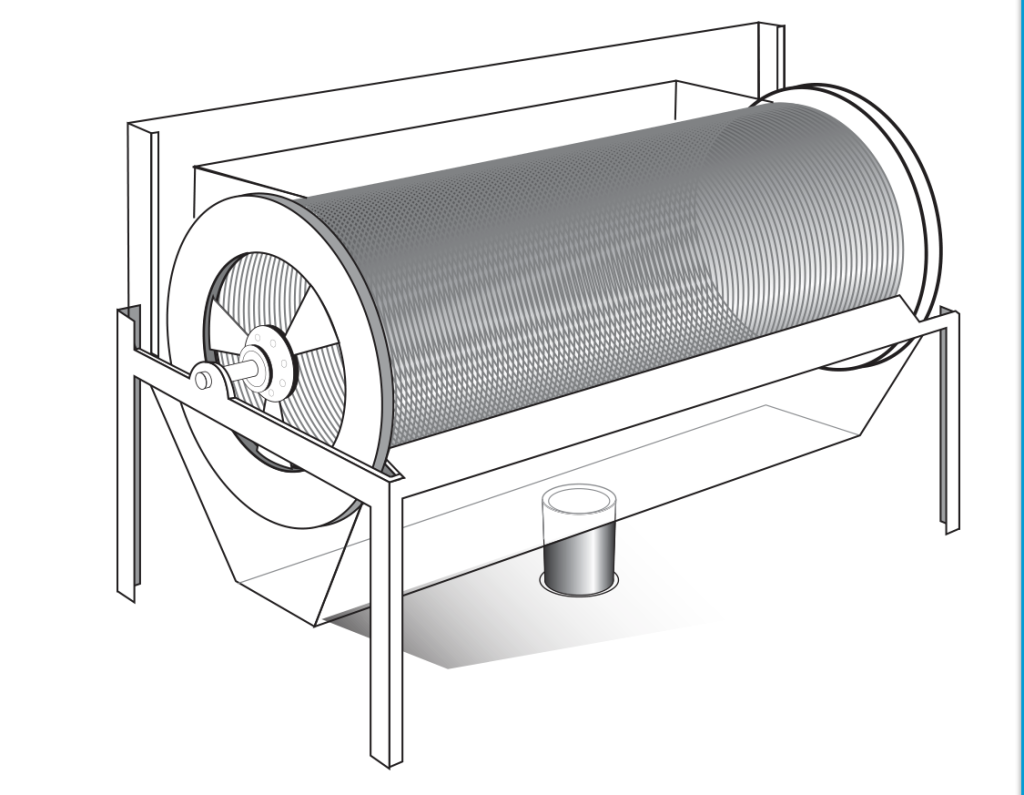

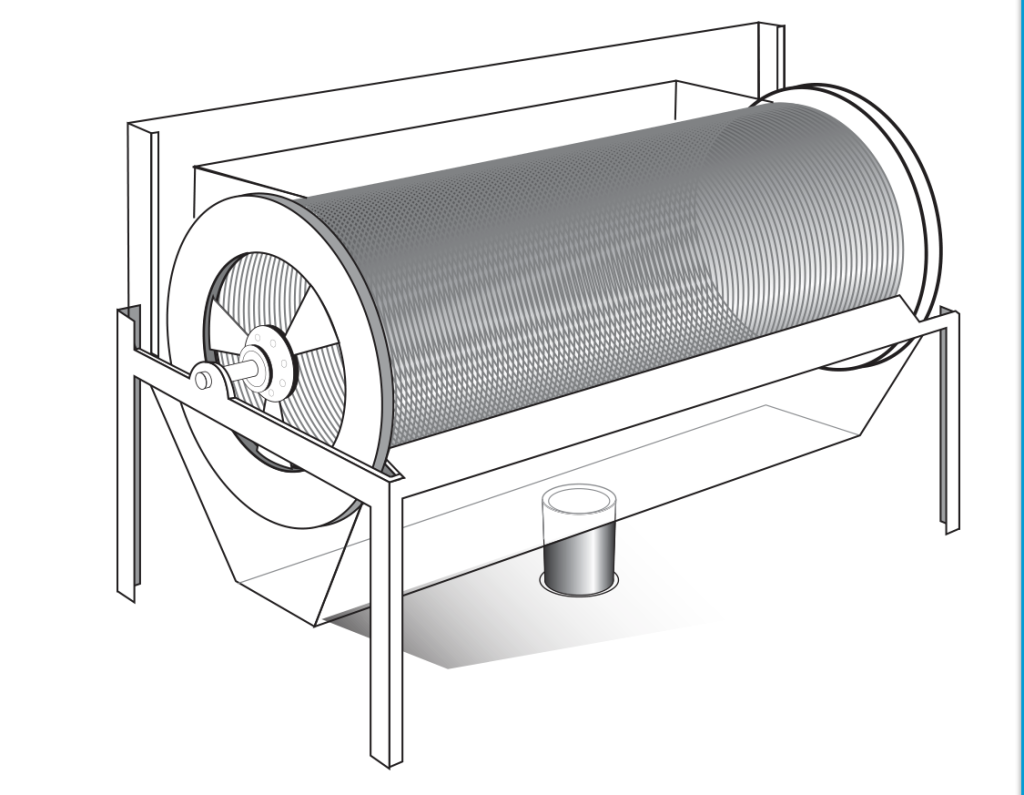

A wedge wire filter is a type of filtration device that utilizes a series of V-shaped, non-clogging wire profiles. These profiles form a continuous slot, which allows for efficient and uniform filtration. The wedge wire screens are constructed using triangular-shaped wire profiles that are welded onto a set of support rods, creating a rigid structure capable of withstanding high pressure and heavy loads.

Uses of Wedge Wire Screens

Wedge wire screens are primarily used for the following applications:

- Water Treatment: They are used in water treatment plants for filtering water from rivers, lakes, and reservoirs. They help remove suspended solids, debris, and other impurities from the water supply.

- Oil and Gas Industry: These screens are used in the oil and gas industry for sand control and filtration in production wells, as well as in various other applications such as mud filtration and catalytic reforming.

- Food and Beverage Industry: Wedge wire screens are used in the food and beverage industry for filtering and separating liquids, such as in wine and beer production, juice processing, and sugar refining.

- Pulp and Paper Industry: They are used for filtering pulp and paper slurries, ensuring a consistent flow of clean, debris-free water throughout the production process.

- Mining and Mineral Processing: These screens are used for dewatering and sizing of minerals, as well as in heap leaching applications.

Size of Wedge Wire Filters

Wedge wire filters come in various sizes, depending on the application and specific requirements. The size of a wedge wire filter is generally determined by the slot width (gap between the wires), wire profile size, and the diameter of the support rods. Slot widths can range from 25 microns (0.001 inches) to several millimeters, while the overall dimensions of the filter can vary from small, handheld devices to large, industrial-sized structures.

Advantages of Wedge Wire Filters

Some of the main advantages of wedge wire filters include:

- Non-Clogging: The V-shaped wire profile and continuous slot design help prevent clogging, as particles larger than the slot width are unable to pass through.

- High Filtration Efficiency: The unique design of the wedge wire filter allows for a uniform and consistent flow of liquid, resulting in efficient filtration.

- High Load Capacity: The rigid structure of the wedge wire screens, created by welding the wire profiles onto support rods, ensures that the filters can withstand high pressure and heavy loads.

- Low Maintenance: Due to their non-clogging and self-cleaning properties, wedge wire filters require minimal maintenance and cleaning.

- Customizable: Wedge wire filters can be tailored to specific requirements, including slot width, wire profile size, and overall dimensions, making them suitable for a wide range of applications.

Wedge wire screens are made of support profiles wrapped with a variety of wedge wires. Its v-shaped structure of it can achieve a large open area and excellent backwash ability. Its special designs work with filtration direction from inside to outside or on the contrary.

Your Specialist & Reliable Manufacturer andSupplier of Wedge Wire Screens .

Benefits :

V type wire, no plugged

No moving part, simple to install

Low maintenance costs

Economical and applicable type, long life

Application:

The wedge wire screen pipe is mainly used for the water-treatment, water well drilling, oil well drilling, mineral processing, coal-cleaning plant, sewage treatment and other industries, water, oil or gas filter, and other filtration equipment.

Specifications of wedge wire screen pipe strainer:

| Material |

SS304, SS304L, SS316, SS316L, SS321, Duplex, Hastelloy, etc |

| OD Range |

19mm-2000mm |

| ID Range |

13mm-1981mm |

| Length Range |

Up to 6000 mm |

| Slot Range |

20 micron to 3000 microns (Tolerance:+-5 micron) |

| Wedge Wire |

0.5×1.5 |

0.75×1.5 |

1×2 |

1.5*2 |

2×3 |

2*4 |

3*5 |

| Support Rod |

1.5×2.5

2×3 |

1.5×2.5

2×3 |

1.5×2.5

2×3 |

1.8*2.5

2×3 |

2×3

2×4

3×5

3×6

3×10

4×7 |

2×4

3×5

3×6

3×10

4×7

5×6 |

3×5

3×6

3×10

4×7

5×6

5×8 |

| End Finishing |

Thread fitting, Flange, Closed Plated, Resistance welded closed plate, Metal Ring, etc |

| Note |

Customized According To Requirement |