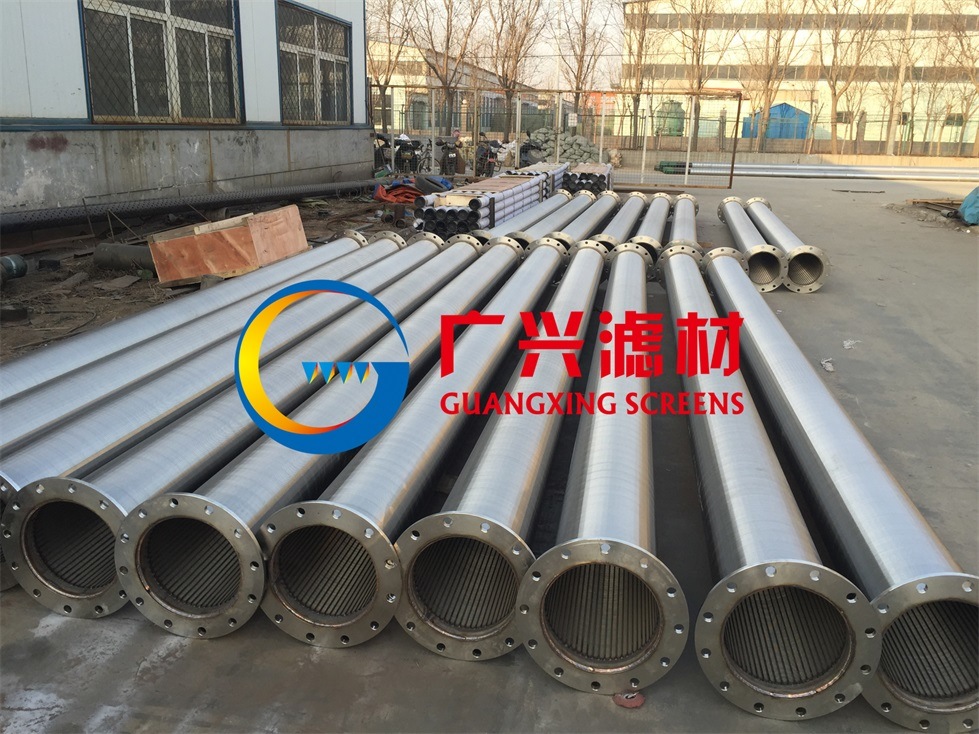

Johnson Stainless Steel Well Screens

September 5, 2023

Stainless Steel Well Screen Materials A Dynamic Study

September 30, 2023What are some examples of the industries and applications that Johnson well Screen serves?

Johnson Screens serves a wide range of industries and applications thanks to the versatility of their continuous slot wire wrapped screens. Here are some examples:

- Water Supply: Johnson’s well screens are widely used in water wells for municipal, rural, and irrigation applications. The screens help filter out sand and other particulates, ensuring a clean and reliable water supply.

- Environmental Monitoring: In environmental monitoring wells, Johnson Screens help in the collection of soil and groundwater samples, essential for assessing environmental impact and for pollution control.

- Oil and Gas Industry: In oil and gas extraction, Johnson Screens are used to filter out particulates and allow fluid flow. They are used in water injection wells, oil wells, gas wells, and more.

- Mining: In the mining industry, Johnson Screens are used for dewatering, mineral processing, heap leaching, and other applications where robust, reliable filtration is required.

- Food and Beverage: The food and beverage industry uses Johnson Screens in a variety of filtration applications, including beer brewing, juice production, and dairy processing.

- Petrochemical Industry: Johnson Screens are used for a variety of filtration and separation processes in the petrochemical industry.

- Architecture: Johnson Screens are sometimes used in architectural applications, where their unique appearance can be used for decorative or functional purposes. Examples may include screens for parking garages, building facades, and landscaping features.

- Industrial Filtration: In various industrial processes, Johnson Screens can be used for filtration, separation, and processing of liquids and gases.

These are just a few examples of the wide range of applications for Johnson Screens. The company’s ability to customize designs based on specific project requirements makes them suitable for use in many other industries and applications as well.

Johnson well Screen Application

Water treatment

Water well drilling

Dewatering well drilling

Oil and gas well drilling

Mineral processing

Coal-cleaning plant

Sewage treatment

Water,oil or gas filter and other filtration equipment.

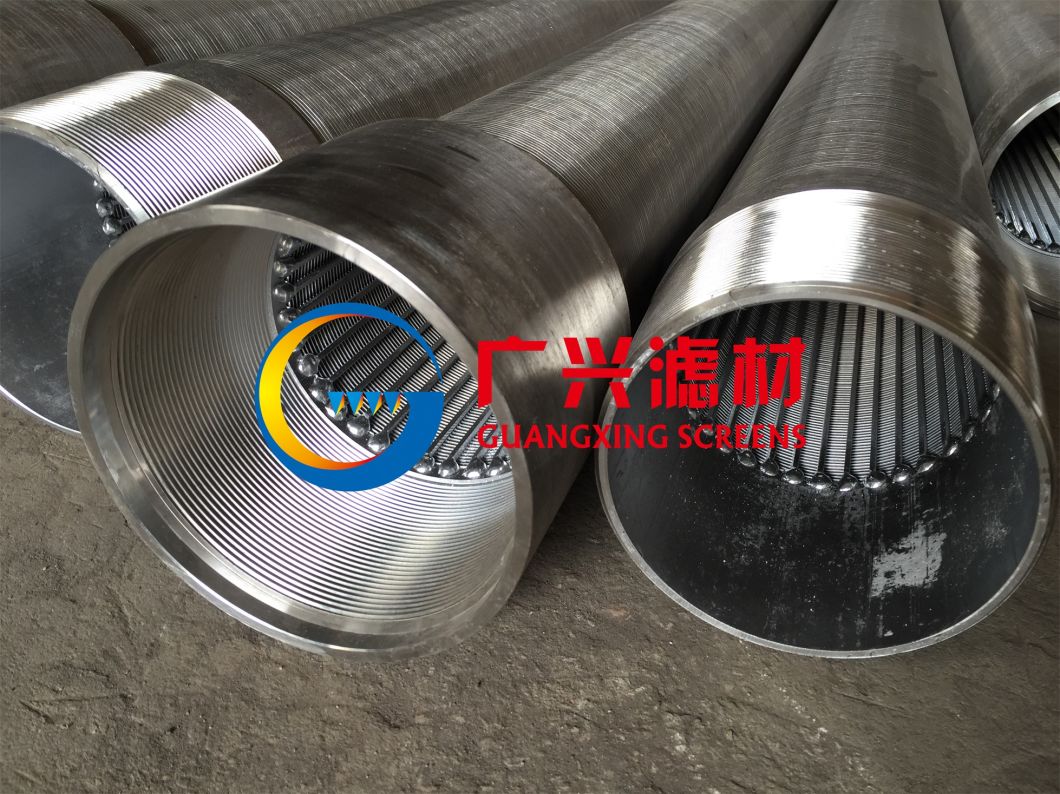

Specification

| Specification (wedge wire): | Width(mm): 1.00 1.00 1.50 1.80 2.00 2.20 2.50 3.00 3.30 3.70 Height(mm): 1.80 2.00 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 10.00 |

| Specification (support rod): | Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

| Note: other specifications available as per request | |

| Slot size: | 0.01mm-10.00mm also achieved upon request. |

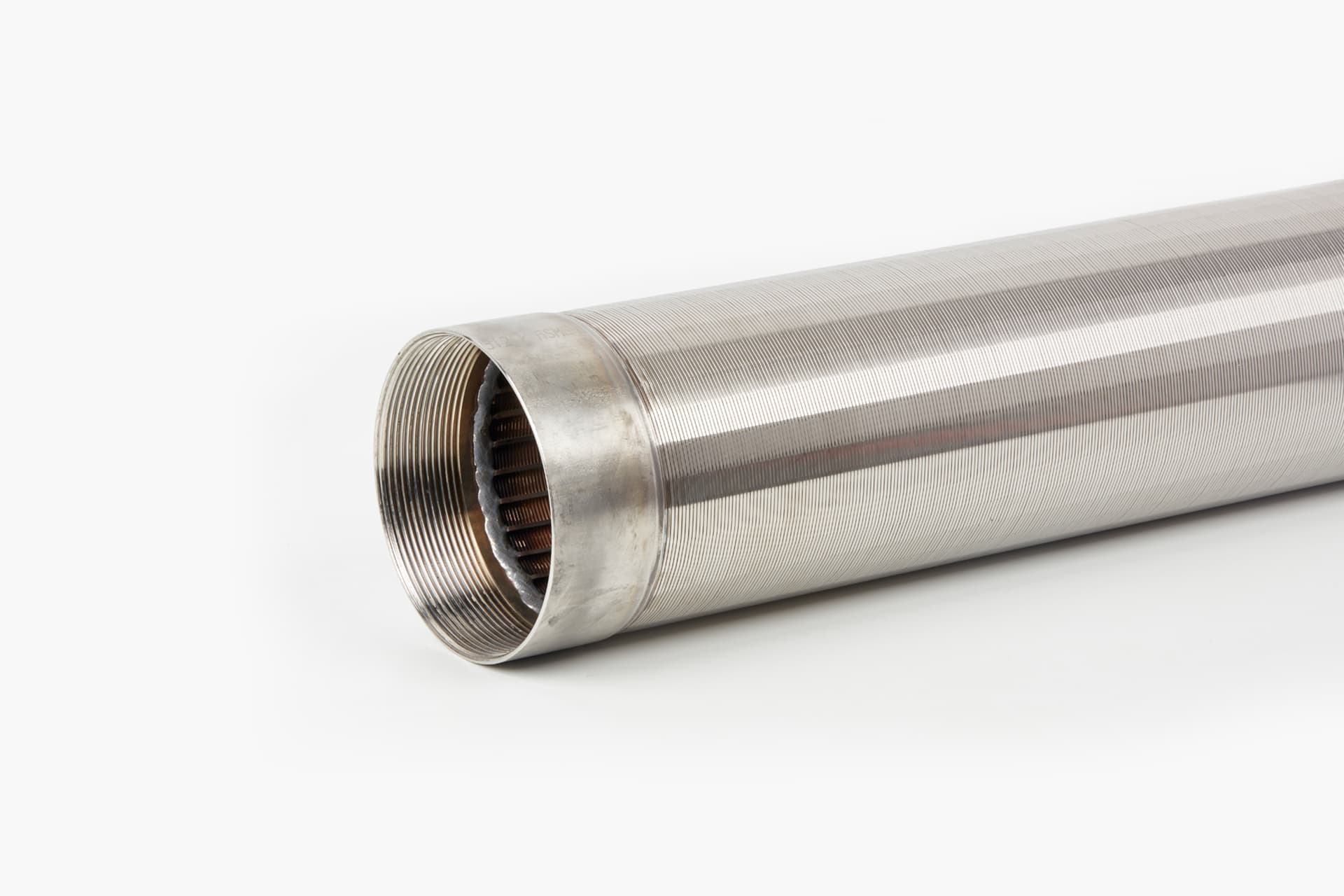

| Material: | galvanized low carton (LCG), stainless steel (304,316L etc.) |

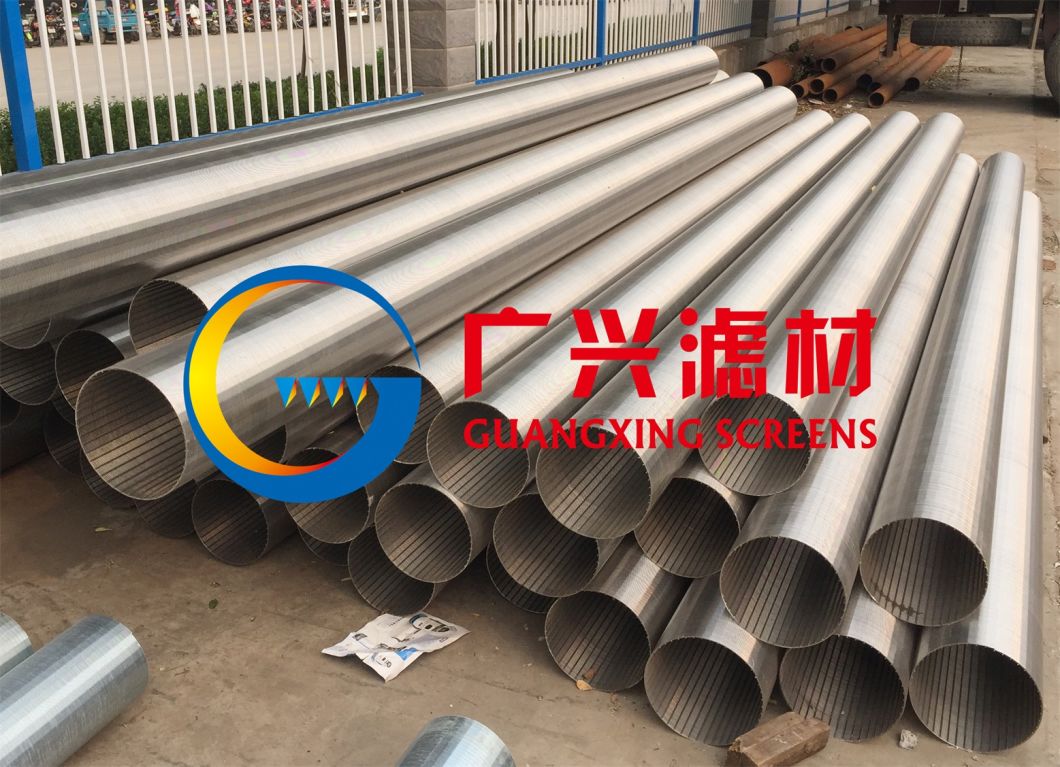

| Length: | up to 6 meters |

| End connection: | Plain beveled ends, flanged or threaded coupling. |

| Diameter: | from 15mm to 1200mm. |

| Note:1.This product can customize according to customer’s actual need.

|

|

How does the continuous slot wire wrapped design of Johnson Screens contribute to their versatility?

The continuous slot wire wrapped design is a key feature of Johnson Screens that contributes significantly to their versatility and efficiency. Here’s how:

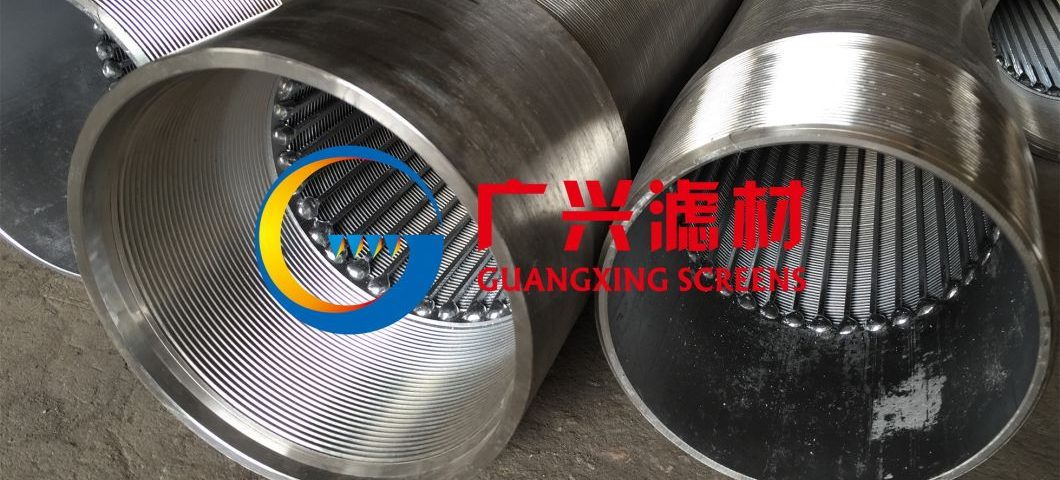

- Uniform Slot Size: The continuous slot design ensures that the slot size between the wrapped wires is uniform. This consistency in slot size allows for effective and predictable filtration, which is crucial in many applications, from water wells to oil and gas extraction.

- Maximum Open Area: The design provides a maximum open area for water to enter the screen, resulting in higher yield and efficiency compared to other screen designs. This is particularly important in water wells where maximizing water flow is critical.

- Non-Clogging: The V-shaped wires allow for a self-cleaning effect. Particles that may potentially clog the screen are less likely to become trapped due to the shape of the wire and increasing slot size in the direction of flow.

- Customizable: The design can be customized in terms of slot size, wire and rod shape, and material to meet the specific needs of a project. This allows the screens to be used in a wide variety of applications across many industries.

- Robust and Durable: The wire wrapped design, combined with the use of materials like stainless steel, results in screens that are robust, durable, and resistant to corrosion. This makes them suitable for use in harsh environments, such as oil and gas wells, mining operations, and more.

In summary, the continuous slot wire wrapped design of Johnson Screens contributes to their versatility by allowing for high flow rates, effective filtration, durability, and customization to suit many different applications.

3