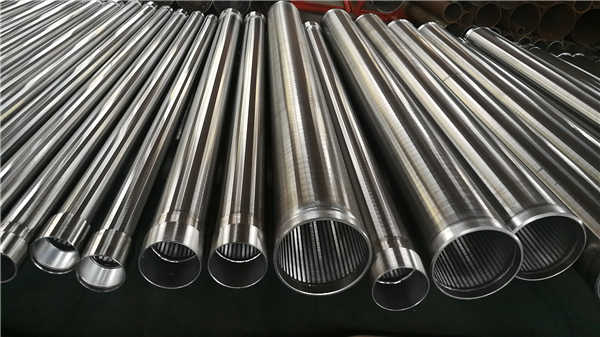

Wedge Wire Slot Well Screens for Water Well Drilling

January 16, 2017

Stainless steel filter cartridge, well screen filter pipe, Johnson well filter,candle filter rod

March 4, 2017Types of wedge wire screen pipe

Wedge wire screen tube has various different types, according to the different standard, here are the detailed introduction of the wedge wire screen tube, just refer to them and know more about the round slot tube and get a reference for choice.

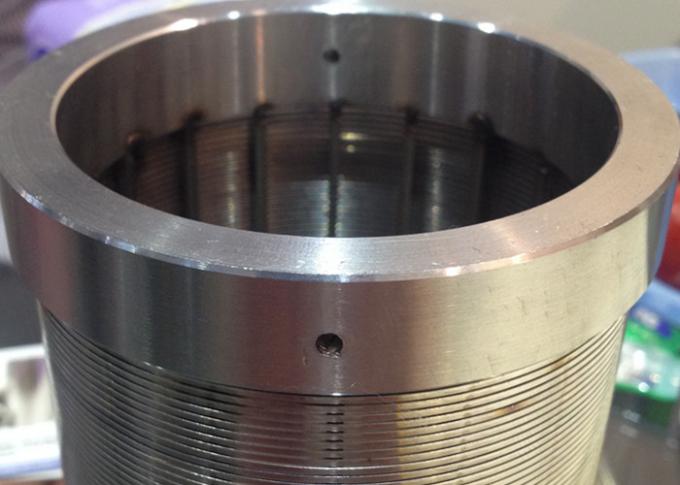

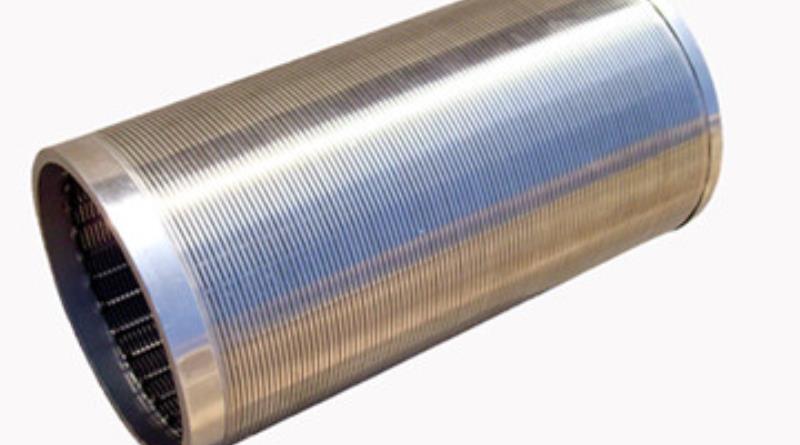

The wedge-shaped silk filter cartridge manufactured by our company is made up of

winding bar winding bar. It has high welding strength, uniform slit, high

accuracy, corrosion resistance, long service life, smooth inner surface of the

filter cartridge and perfect roundness. Our filter cartridge is widely applied

to all kinds of large and medium-sized filtration equipment, such as automatic

cleaning filter, scraper filter, automatic blow down filter, rotary fine grille

filter, drum fine grille, rotary screen and other solid-liquid separation

equipment. The filtration precision of the wedged wire filter is 0.02mm-10mm,

the structure is reasonable and the service life is long. It is one of the best

filter elements so far. The main material is made up of 304, 316L.

Note:

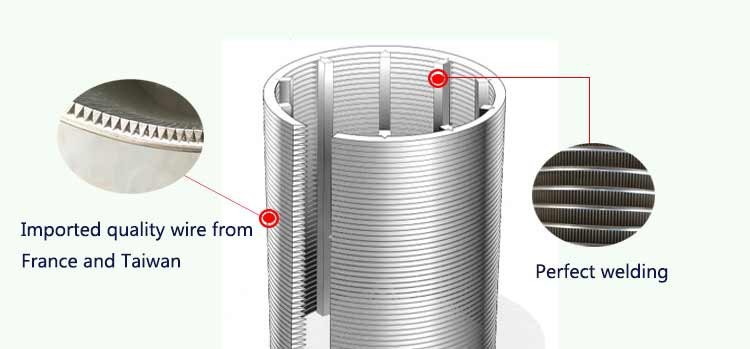

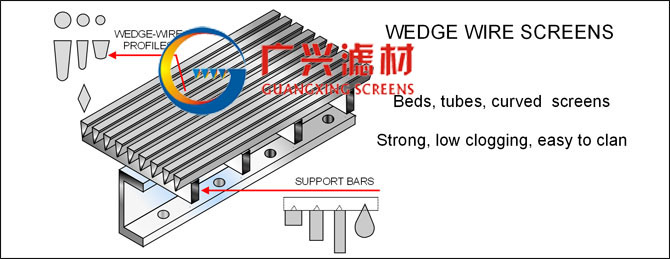

Slot Size (S): The distance between each profile wire.

Profile Wire: Triangle wire is common type.

Support Rod: Triangle wire is common type. It can also be round rod, flat bar, wedge wire.

Support Rod Distance (P): The distance between each support rod.

Wedge wire screen tube ending types

Johnson screen/wedge wire screen tube technical parameter:

For wedge wire screen tube, profile wire type is generally triangle wire.

Support rod includes triangle wire, round bar, flat bar and wedge wire.

The length of wedge wire screen tube is 0.3m,0.6m,1m,2m,3m,6m,12m.

Wedge wire screen pipe profile wire size

| Surface profiles | Support profiles | Min.diam. in mm | Min. slot width in mm |

| 10S | Q25 | 21 | 0.10 |

| 11S | Q20 or Q25 | 23 | 0.030 |

| 12S | 22S | 30 | 0.050 |

| 12S | Q25 | 23 | 0.030 |

| 12S | Q35 | 30 | 0.050 |

| 18S | 22S or Q35 | 30 | 0.050 |

| 18S | Q25 | 25 | 0.030 |

| 18S | D45 | 300 | 0.20 |

| 18S | 10×3 | 300 | 0.20 |

| 22S | 22S or Q35 | 45 | 0.10 |

| 22S | D45 or 10×3 or 25×3 | 300 | 0.20 |

| 28S | Q35 | 215 | 0.20 |

| 28S | D45 or 10×3 or 25×3 | 300 | 0.20 |

| 34S | Q35 | 300 | 0.20 |

| 34S | D45 | 300 | 0.20 |

| 34S | 10×3 or 25×3 | 300 | 0.20 |

| 42S | Q35 or D45 | 300 | 0.20 |

| 42S | 10×3 or 25×3 | 300 | 0.20 |

Pipe specification

| 2 3/8 | 2 .375 | 2 |

| 3 1/2 | 3.5 | 3.1 |

| 4 | 4 | 3.5 |

| 4 1/2 | 4.5 | 4 |

| 5 | 5 | 4.5 |

| 5 1/2 | 5.5 | 5.0 |

| 6 5/8 | 6.63 | 6.1 |

| 7 | 7 | 6.5 |

| 7 5/8 | 7.63 | 7.0 |

| 8 5/8 | 8.63 | 8.1 |

| 9 5/8 | 9.63 | 9.1 |

| 10 3/4 | 10.75 | 10.1 |

| 12 3/4 | 12.75 | 12 |

| 14 | 14 | 13.2 |

| 16 | 16 | 15.2 |

| 18 | 18 | 17.2 |

| 20 | 20 | 19.1 |

| 24 | 24 | 23 |

| 30 | 30 | 28.7 |

| 32 | 32 | 30.7 |

It can also be designed and produced according to the requirements of the

customer.

The fully welded wire winding screen can be made of stainless steel, as long as

it is used for sand control, chemical industry, papermaking, water treatment and

other industries in oil, gas and water wells, and sieve plates are mostly used

for water treatment and papermaking industry. Gap size (mm): 0.02, 0.04, 0.05,

0.1, 0.15, 0.2, 0.25, 0.30,… 4, and adjust according to the user’s request.

Note: the outer diameter of the sieve tube is related to the selection of the

size of the sieve bar. The diameter of the sieve tube is between 19 and 900, and

the length of the sieve can be processed according to the user’s requirement

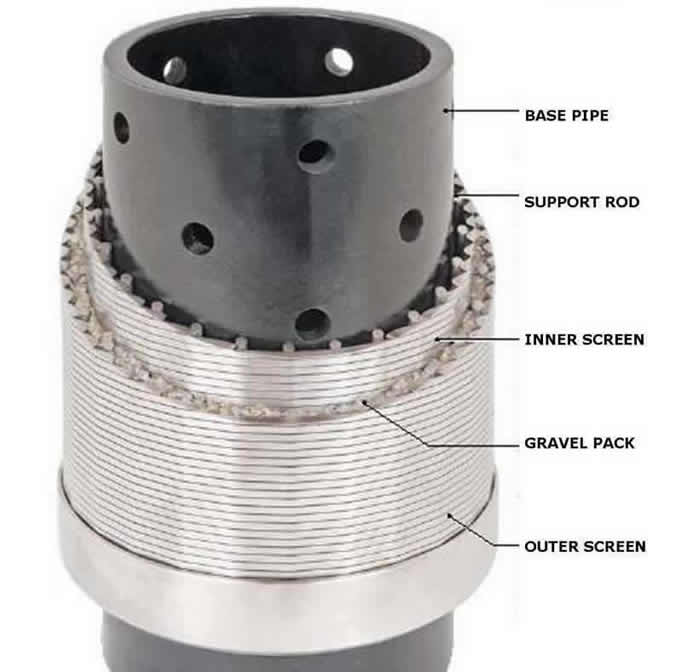

between 23-3000mm. Double screen prepack dual screen prepack is a monolayer of

different diameter wire wrapped screen together, closed pre filled quartz sand

after solid annular space formed in the double screen, which is dense, fastening

filling the quartz sand, to achieve the “sand” effect, can reduce construction

time, effective fast effect.

The sieve tube can be used for the use of dehydration and stripping. It includes

the plane sieve plate, the arc sieve plate, the jigging sieve plate and the

centrifugal sieve basket. The sieving crevice of the sieve tube from 0.02-45mm,

a total of 100 a variety of specifications. Our factory can produce all kinds of

sieve tube products according to the needs of user service.

If the stainless steel screen is used as the material, it is called stainless

steel screen pipe, which is made of advanced stainless steel wire with special

section and welded by advanced technology. It has the characteristics of simple

structure, convenient use, high strength, light weight, strong corrosion

resistance, large filtration area and good percolation performance.

Well Screen Applications

Water Wells

Support and filter medium

Solid-liquid separation

Filter application

Sewage treatment

Dehydration application

Sand treatment

The surface is smooth and smooth, the clearance is uniform, the roundness is

perfect, and the minimum gap can be made of 2 silk. Can provide small sample!

More than the same industry in China!