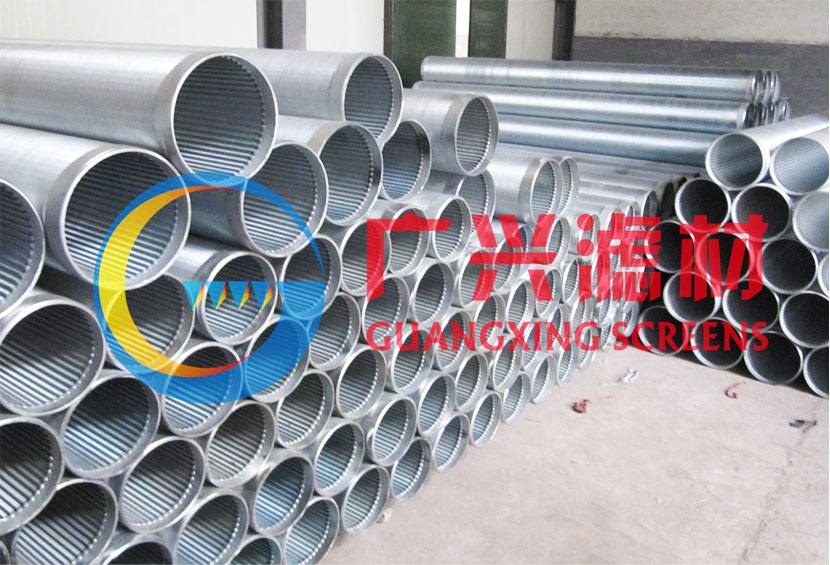

Sand control technology of wire wrapped liner pipe

February 27, 2018

ASTM A312/A312M stainless steel Perforated Casing Pipe

March 8, 2018Slotted liner is a robust and effective device for sand control in the horizontal completion wells of SAGD and other thermal heavy oil recovery. Its excellent properties in withstanding installation loads and operation loads make it the premier choice for SAGD.

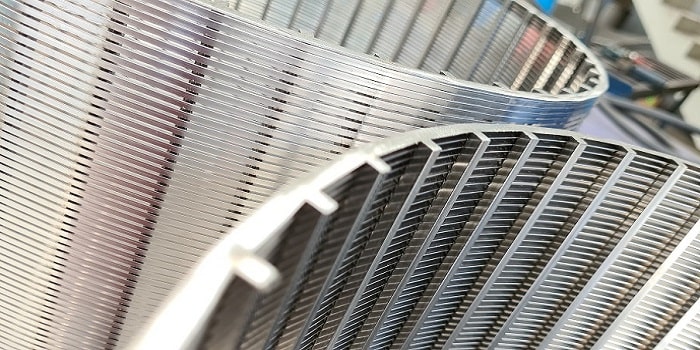

Slotted liners are manufactured by laser cutting process without contact operation. This process can effectively avoid undesirable factors which will cause the deformation of the base pipe. Laser cutting process uses windows interface for easy operation and accurate calculation.

Slotted liner geometry consists of slot length, slot width, slot density and slot distribution. All these parameters can be bespoken to achieve the required open area. For example, multiple staggered pattern or gang pattern significantly increases the open area compared with single cut pattern.

stainless steel 304 slit filter screen Description: 304 stainless steel filter screen is in the pipe casing or tubing in a variety of ways to cut a number of vertical or spiral of a certain vertical straight, staggered slot. Using a special ultra-thin cutting and cutting the beam, the slit width (0.2-0.5 …Be applicable:Applicable to the construction of hydrogeology, coalfield geology, chemical geology, metallurgy geology, geothermal air conditioning, foundation precipitation, water source development, urban water supply and other navigation also construction.

Staggered slotted liner fabricated by advanced laser cutting process

304 stainless steel filter is the filter tube in the casing or tubing on the oil in a variety of ways to cut a number of vertical or spiral of a straight line, staggered slit.

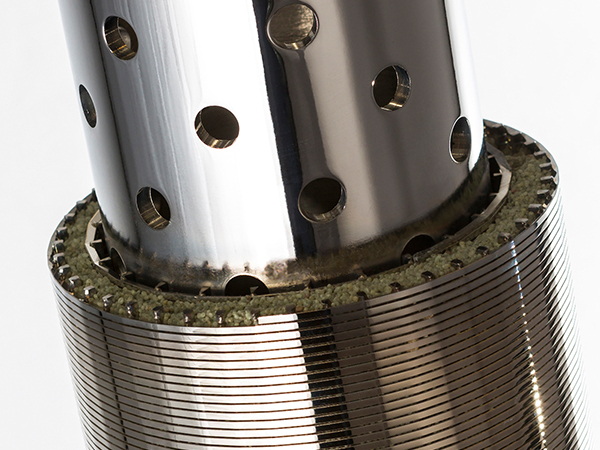

Using a special ultra-thin cutting blades and beams made of cutting, the slit width (0.2-0.5mm). The cross section is rectangular, trapezoidal (trapezoidal angle of 3-8 degrees) and special shape (round hole) and other forms, to ensure permeability of 0.5% -10%, the layout of the gap can be processed according to user requirements.

304 stainless steel filter screen features:

1, 304 stainless steel filter screen filter for sand out of sand larger than 0.3mm sand control.

2, kerf edge perpendicularity is good, trimming smooth, burr-free, kerf uniform.

3, large flow area, 27/8 “screen 300 kerf / 1.5m, than the same size tubing flow area 2.4 times larger.

4, the overall anti-corrosion treatment to improve the corrosion resistance of the screen and wear Can extend the working life of its underground

5, the use of J55 or N80 oil casing body processing, high strength, not easily deformed

6, within the large diameter, easy to configure the tube string.

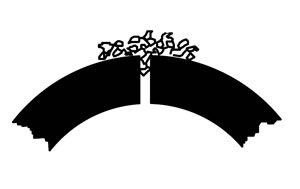

Slotted liner patterns

Three slotted liner patterns -straight, staggered and gang – are supplied. Each has its own characteristics.

|

|

| Straight cut slot | Keystone slot |

Slotted geometry

Slotted shapes are classified into two types: straight cut slot and keystone slot. Compared with straight slot, keystone slot has higher resistance against plugging for its inter size is larger than the surface size. Once the sand entering the keystone slot, the possibility of clogging will drop sharply.

Notes:

For more information about slotted liner, please consult slotted liner basic knowledge.

Features:

Moderate cost

Ease of installation

Sufficient operation load

Non-plugging

Laser cutting process

Product specification

| Required slot per ft. for 3% open area | |||||

| Slot Width (mm) | Slot Width (inch) | 3.5″ Liner | 4.5″ Liner | 5.5″ Liner | 7″ Liner |

| 0.38 | 0.015 | 176 | 228 | 276 | 352 |

| 0.45 | 0.018 | 148 | 188 | 232 | 296 |

| 0.5 | 0.020 | 132 | 172 | 208 | 264 |

| 0.63 | 0.025 | 108 | 136 | 168 | 212 |

| 0.7 | 0.028 | 96 | 124 | 148 | 188 |

| 1 | 0.038 | 52 | 68 | 84 | 104 |

| 1.5 | 0.058 | 36 | 44 | 56 | 68 |

| 3 | 0.125 | 16 | 24 | 28 | 32 |

| 6 | 0.250 | 8 | 12 | 16 | 16 |

Slotted liner in gang pattern or staggered patter