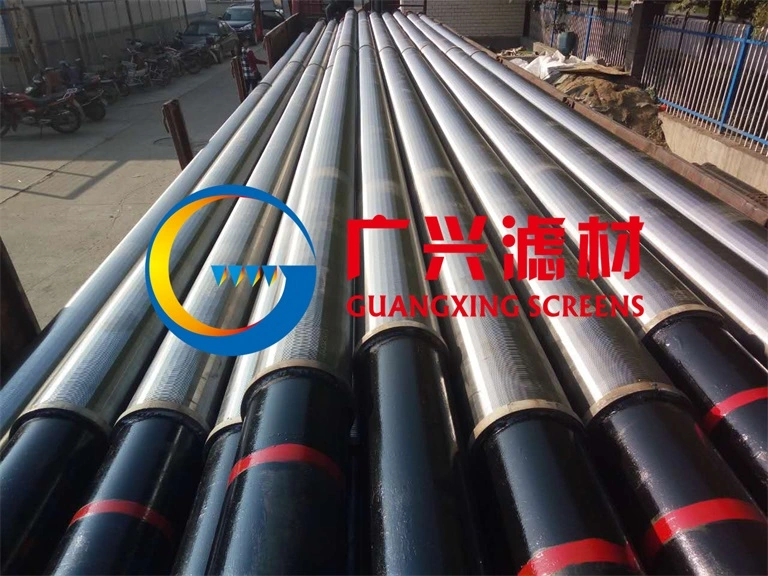

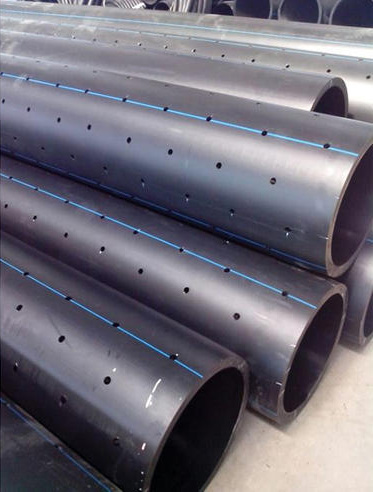

API sand control screen for oil well,filter pipe

April 26, 2018

Screw Press Screens,screw press wastewater treatment

April 30, 2018After a well is drilled, an essential part of the completion process is to make a connection between the wellbore and the reservoir of oil or gas that needs to be pumped out. For production and injection wells, alike, this is a crucial phase since the quality of the connection has a major influence on well’s future performance.

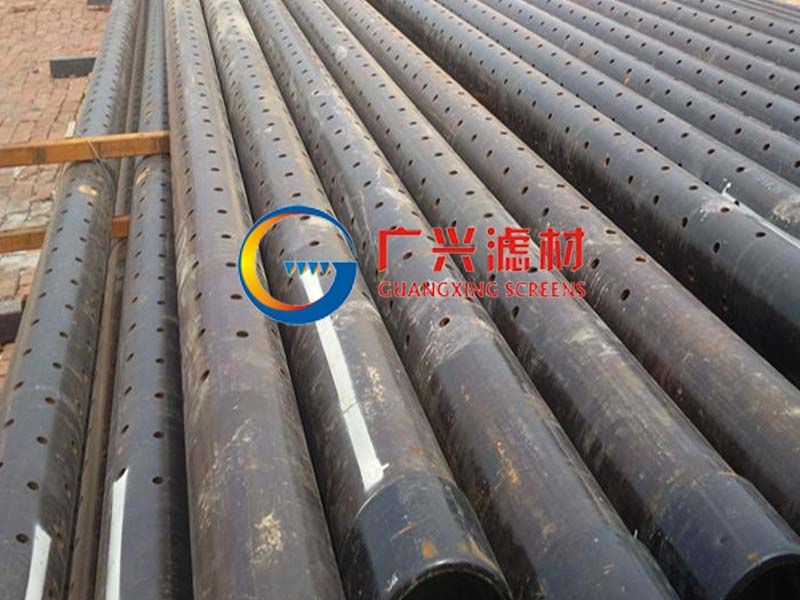

Well perforating is the process of punching a hole in the well’s cement liner (or casing) in order to enable the reservoir connection to be made. Establishing a connection to the wellbore means the well can begin to flow and production can begin. For injection wells, it means that injection can commence.

In the vast majority of cases, wells are perforated using high energy shaped charge explosives. The shaped charges are held in perforating guns and when fired, they have enough power to punch through the liner or casing and into the bedrock.

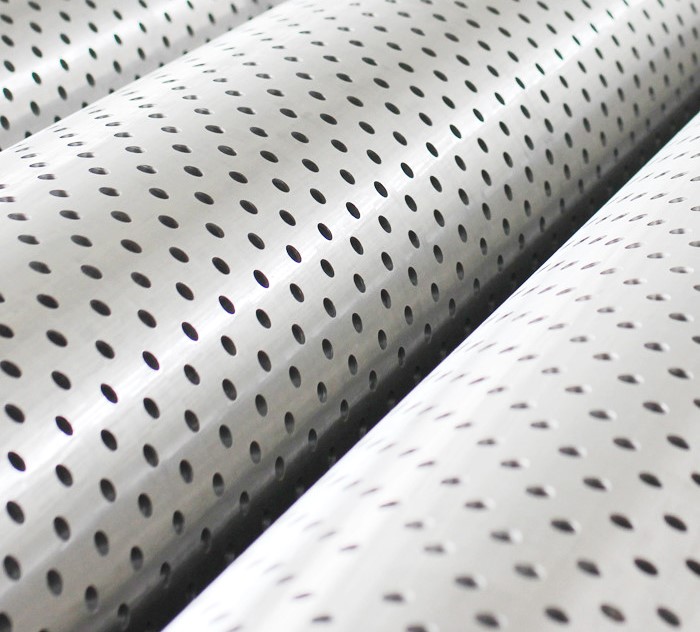

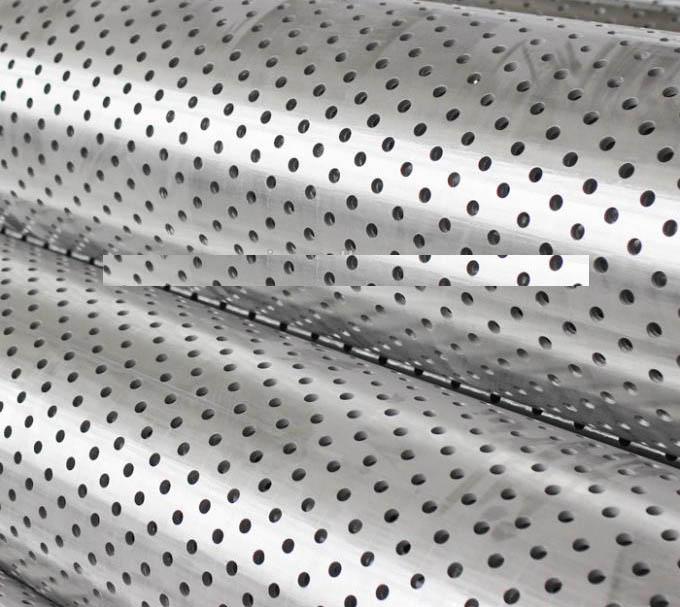

the size and distribution of perforated hoses pose a direct impact on well productivity.

Features:

Available in J55 or N80. J55 and N80 have high strength and less potentiality of deformation.

Punched hoses are smooth and clear without burrs.

Easy installation.

Overall preservative treatment creates a dense protective layer over the surface of the pipe and improves corrosive resistance.

Six types of punched hoses are available for specific application.

Two types of hoses distribution are manufactured.

The perforating process

Perforating guns are designed to hold an array of shaped charges and they are lowered into the well on slickline, E-line, or coiled tubing to the depth where the connection to the reservoir needs to be made. The gun is then fired electrically to shoot multiple holes in the casing interval that the gun has been lowered to. Sometimes hundreds if not thousands of holes are made.

PERFORATED CASING AND SCREEN PIPE IN OIL WELLS.

intended to overcome the cutting action of the fine sand, carried into

the well under high pressure, which destroyed other types of screen.

It is not uncommon to have wells sand up in six to eight months’ time, making redrilling necessary to re- store thc production. The screen is made by placing a No. 60, 62-inch Getty screen over a No. 40, 3å-inch Getty screen and filling the Ln- nular space between with carborundum.

Details concerning the construction are shown in figure G. A special steel adapter ring, B, is screwed into a 61- inch, 8-thread coupling, A. The 31- inch liner pipe J with the No. 40 screen E is then screwed into the ring B; the 62-inch pipe with NO. 60 Getty screen C is placed over the smaller pipe and screwed into the coupling A. The screen filled with carborundum, rolled and shaken in order to work down the car- borundum filling thoroughly. pack the space solidly, and fill the {-inch holes on the inside of the outcr screen. A space of nine inches is left between the top of the carborundum and the top of the pipe.

Product parameters

|

Pipe Size (inch) |

Number of hoses (sq in./ft) |

Hole Diameter (inch) |

Open Area (sq in./ft) |

|

3/4 |

78 |

3/16 |

2.15 |

|

1 |

54 |

5/16 |

4.14 |

|

1-1/4 |

66 |

5/16 |

5.06 |

|

1-1/2 |

78 |

5/16 |

5.98 |

|

2-1/16 |

78 |

5/16 |

5.98 |

|

2-3/8 |

90 |

3/8 |

9.94 |

|

2-7/8 |

102 |

3/8 |

11.26 |

|

3-1/2 |

126 |

3/8 |

13.91 |

|

4 |

138 |

3/8 |

15.24 |

|

4-1/2 |

150 |

3/8 |

16.56 |

|

5 |

162 |

3/8 |

17.88 |

|

5-1/2 |

174 |

3/8 |

19.21 |

|

6-5/8 |

186 |

3/8 |

20.53 |

|

7 |

222 |

3/8 |

24.51 |

|

9-5/8 |

294 |

3/8 |

32.46 |