Well screen selection & Drilling methodology

November 21, 2017

HOW TO SELECT Well Screens and Gravel Packs?

November 23, 2017To keep loose sand and gravel from collapsing into the borehole, it is necessary to use well casing and screen. The screen supports the borehole walls while allowing water to enter the well; unslotted casing is placed above the screen to keep the rest of the borehole open and serve as a housing for pumping equipment. Since the well screen is the most important single factor affecting the efficiency of a well, it is sometimes called the “heart of the well”!

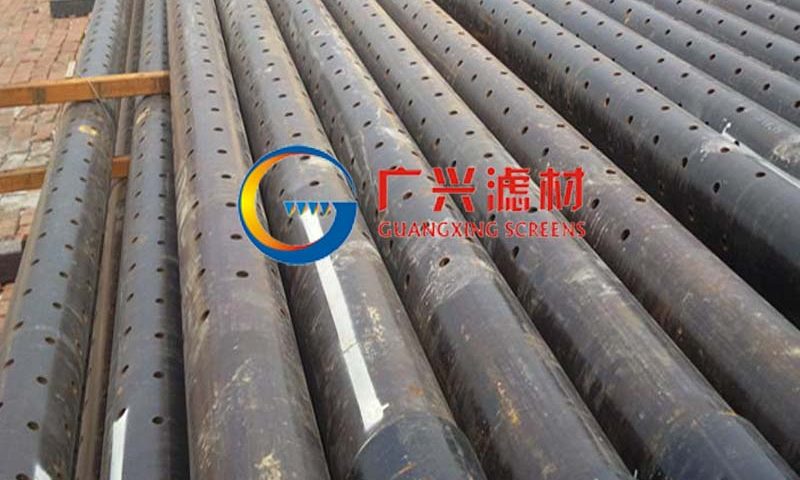

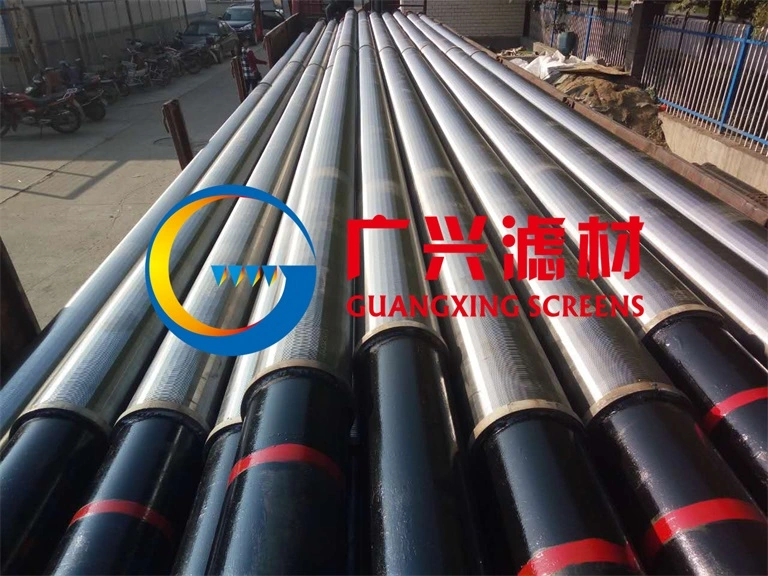

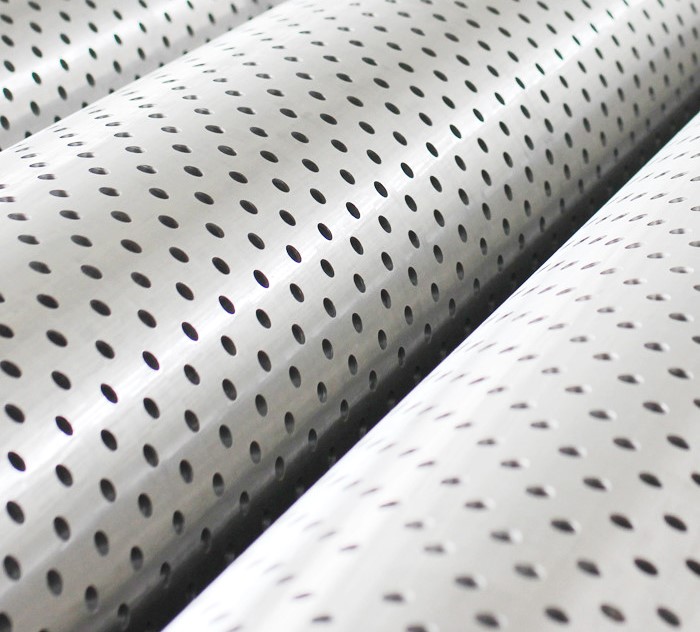

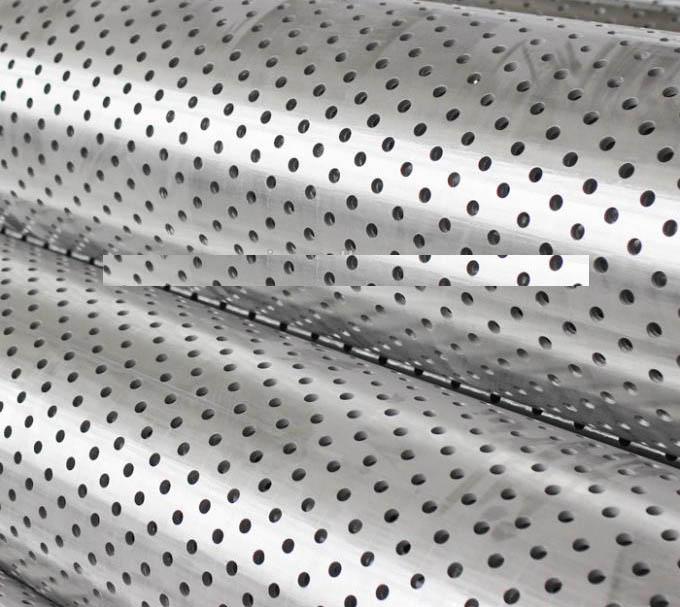

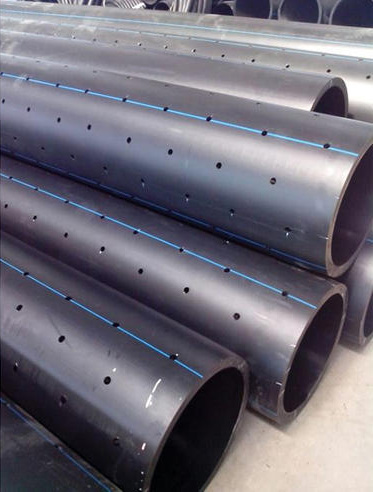

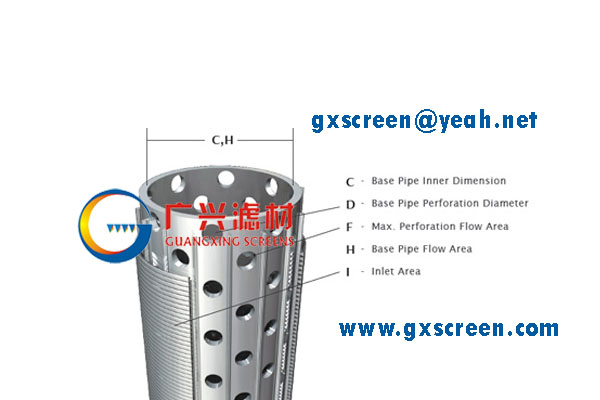

Slotted/perforated pipes and tubes are common casing layer for pipe-core wire wrapped well screens. The perforated casing tube has round holes uniformly distributed for smooth flow of the liquid. It is actually a supporting pipe for sand control system in drilling oil or water wells. The metals are mostly stainless or mild steel.

How it Works: Perforated pipe or punched tubing is used as connection support. It links the wellbore and the producing formation through punched holes in the casing and the cement sheath that surrounds it.

Three standard pore size selections: 150 microns, 225 microns, 300 microns

Diameters available to fit base pipe sizes of 4.5″, 5.5″, and 6.625″

Continuous lengths of up to 18.5′

316L SS wire cloth filter media

304 SS perforated outer shroud

Thermally processed to create a stabilized pore structure

TIG welded longitudinal seam and end rings

The continuous slot screen has much large open area compared to other types of screens. The obvious advantages are that restrictions to flow into the well are reduced, well losses are minimised thus resulting in considerable savings in pumping costs. The screen also allows maximum development efficiency.

Throughout the manufacturing process screen slot size is closely monitored to ensure that tolerances are maintained. This, and other rigorous dimensional and quality control checks assure uniformity of all components. This permits strength and flow calculations to be made within narrow limits.

The basic design consists of welded screen jacket telescoped over a perforated pipe base or over another welded screen base.

More Technical Details:

Perforated casing screen pipes, J55 or N80

Perforated casing screen pipes, J55 or N80

The size and distribution of perforated hoses pose a direct impact on well productivity.

Features:

Available in J55 or N80. J55 and N80 have high strength and less potentiality of deformation.

Punched hoses are smooth and clear without burrs.

Easy installation.

Overall preservative treatment creates a dense protective layer over the surface of the pipe and improves corrosive resistance.

Six types of punched hoses are available for specific application.

Two types of hoses distribution are manufactured.

Screen/Casing Diameter: Three inch diameter casing and screen can be easy inserted into the 15 cm (6 in) LS-100 borehole and allows creation of an effective 3 cm (1.25 in) thick filter pack (this is especially important where the aquifer is composed of very fine materials). However, since 7.6 cm (3 in) screen is often not available and has low total open area, carefully centered and filter packed 10 cm (4 in) screen is most frequently used. Larger diameter screens make the filter pack ineffective and do NOT significantly increase well yield. For example, moving from a 10 – 12.7 cm (4 – 5 in) screen will increase yield by 3 percent or less! Besides, a good filter pack expands the effective radius of the well to the full 15 cm (6 in) diameter of the borehole.

Features of wedge wire screen

Brief introduction of Schroeder Technology and wedge wire screen.

Wedge wire screen is made of wedge shape stainless steel wire. And it is widely used in beverage / beer filtration, paper making industry, industrial waste water treatment, oil, water desalination and etc.

Schroeder technology are expert at manufacturing small diameter wedge wire screen. The goods are high quality and high precesion. In wedge wire screen filter feild, there are some good suppliers. Trislot from Belguim, Euroslot from Germany and etc. Schroeder Technology also have our own brand.