Perforated Casing Filter Pipe stainless steel

November 15, 2017

ASTM A 312 stainless steel 316L Perforated Casing screen Pipe

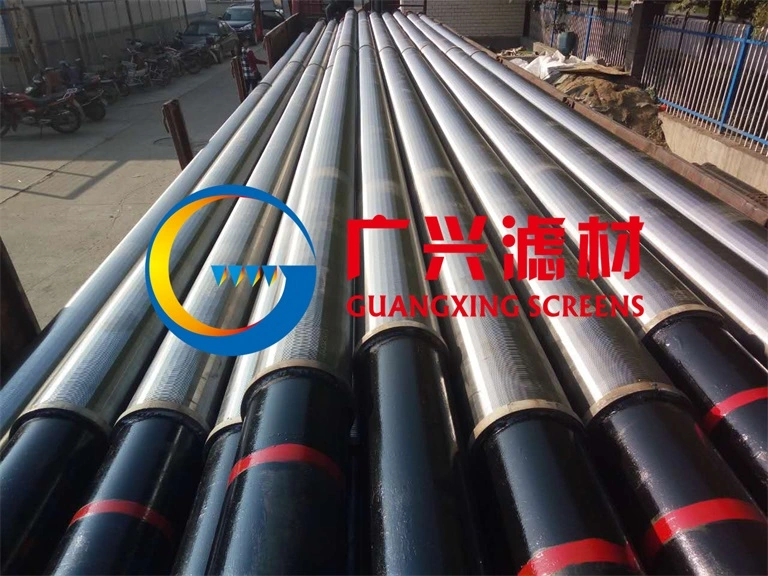

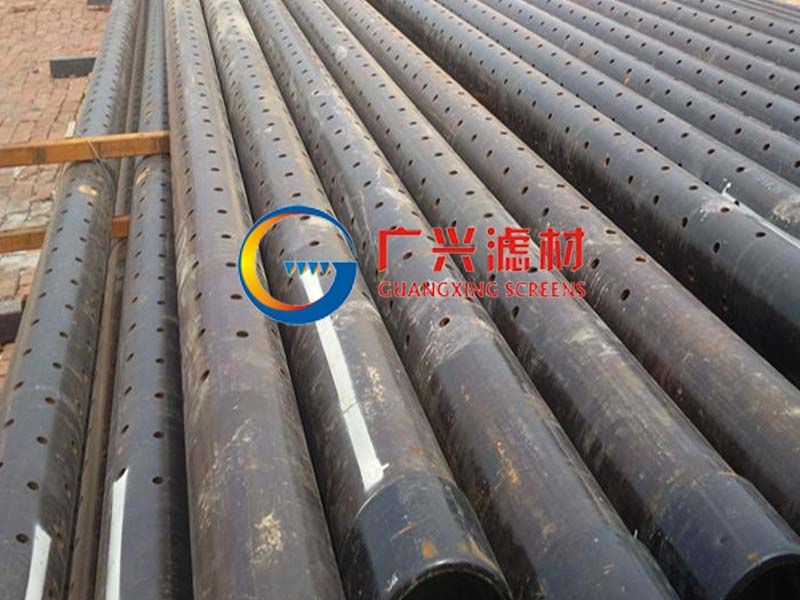

November 15, 2017Pipe based well screens consist of base pipe, all-welded wedge wire screen and supporting rod. The base pipe is perforated or slotted API casing pipe, the base pipe can be stainless steel or carbon steel API 5CT casing. The all-welded wedge wire screens are welded together with base pipe by supporting rod.

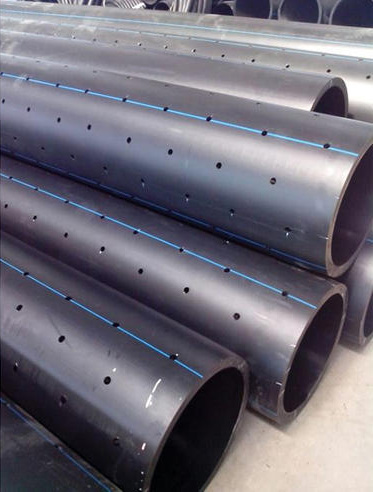

Perforated Based Pipe with Screen Jacket are used for deep water well application and oil field application. It is used for sand control in wells with high pressure and high traction value due to the depths. Pipe based well screens consist of base pipe, all-welded wedge wire screen and supporting rod. The base pipe is perforated or slotted API casing pipe. The base pipe can be stainless steel or carbon steel API 5CT casing. The all-welded wedge wire screens are welded together with base pipe by supporting rod.Having the API casing inside a wire wrap screen jacket is supporting the screen and enhance the cabapities and high tensile strength Loads. Pipe base can be made from API pipe Seamless casing spiral or stainless steel casing. Opening area for the base pipe is up to 15% and for the jacket is up to 30%. Jacket slot size is between 0.15mm to 3mm.

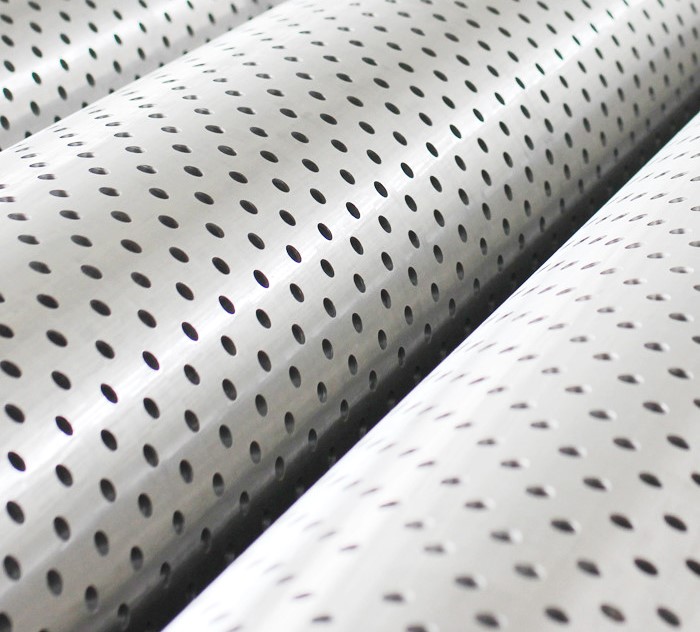

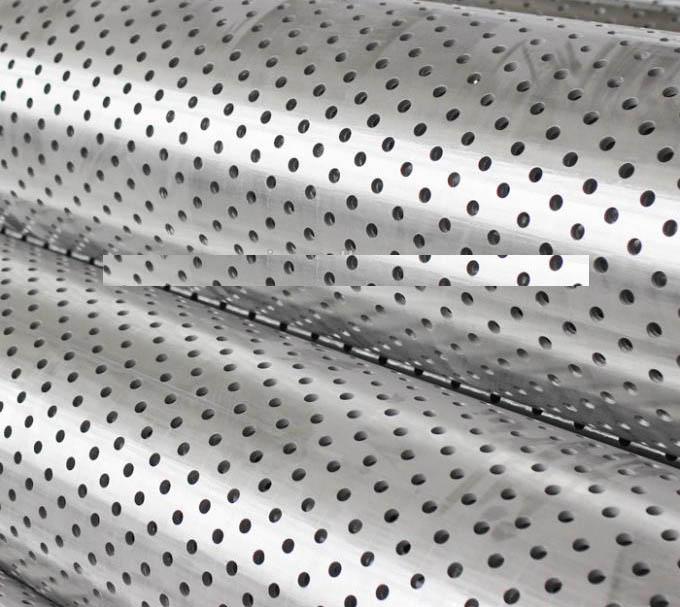

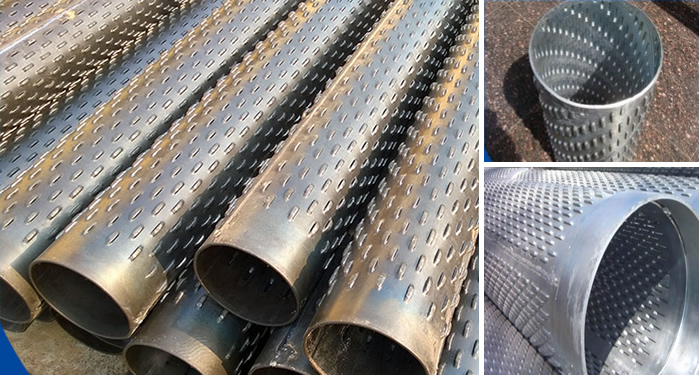

Micron opening perforated metals are used as filters or screens itself in the screening of coal, gravel and ore; in the shifting and separation of food products and medical material, water well screening, sand control. Made of quality stainless steel or carbon steel sheets, perforated filter tubes and cylinders can be made spiral welded or butt welded in a wide range of sizes.

Primarily used in automotive and filtration applications, perforated tubes are often subject to design requirements, stringent inspections, and competitive pricing. This in mind, we developed a proprietary system that is so unique it not only can produce practically any pattern, but the tightest tolerance perforated tubes available on the market.

Completely perforated or with blank areas, one hole size or a variety of them, straight or flared ends, perforated tubes can be made up to 6 inches in diameter and 30 inches in length in any metal type or thickness.

| Base pipe | Screen jacket | |||||||||

| Nominal diameter (in) |

Outside diameter (mm) |

Weight(1b/ft) Wall thickness (mm) |

Hole diameter (in) |

Hole Density |

Hole area (in2/ft) |

OD of screen Jacket (in) |

Open area (in2/ft) |

Slot (in) |

||

| 0.008″ | 0.012″ | 0.015″ | 0.020″ | |||||||

| 2-3/8 | 60 | 4.6(4.83) | 3/8 | 96 | 10.60 | 2.86 | 12.68 | 17.96 | 21.56 | 26.95 |

| 2-7/8 | 73 | 6.4(5.51) | 3/8 | 108 | 11.93 | 3.38 | 14.99 | 21.23 | 25.48 | 31.85 |

| 3-1/2 | 88.9 | 9.2(6.45) | 1/2 | 108 | 21.21 | 4.06 | 18.00 | 25.50 | 30.61 | 38.26 |

| 4 | 101.6 | 9.5(5.74) | 1/2 | 120 | 23.56 | 4.55 | 20.18 | 28.58 | 34.30 | 42.88 |

| 4-1/2 | 114.3 | 11.6(6.35) | 1/2 | 144 | 28.27 | 5.08 | 15.63 | 22.53 | 27.35 | 34.82 |

| 5 | 127 | 13(6.43) | 1/2 | 156 | 30.63 | 5.62 | 17.29 | 24.92 | 30.26 | 38.52 |

| 5-1/2 | 139.7 | 15.5(6.99) | 1/2 | 168 | 32.99 | 6.08 | 18.71 | 26.96 | 32.74 | 41.67 |

| 6-5/8 | 168.3 | 24(8.94) | 1/2 | 180 | 35.34 | 7.12 | 21.91 | 31.57 | 38.34 | 48.80 |

| 7 | 117.8 | 23(8.05) | 5/8 | 136 | 42.16 | 7.58 | 23.32 | 33.61 | 40.82 | 51.95 |

| 7-5/8 | 194 | 26.4(8.33) | 5/8 | 148 | 45.88 | 8.20 | 25.23 | 36.36 | 44.16 | 56.20 |

| 8-5/8 | 219 | 32(8.94) | 5/8 | 168 | 51.08 | 9.24 | 28.43 | 40.98 | 49.76 | 63.33 |

| 9-5/8 | 244.5 | 36(8.94) | 5/8 | 188 | 58.28 | 10.18 | 31.32 | 45.15 | 54.82 | 69.77 |

| 10-3/4 | 273 | 45.5(10.16) | 5/8 | 209 | 64.79 | 11.36 | 34.95 | 50.38 | 61.18 | 77.86 |

| 13-3/8 | 339.7 | 54.5(9.65) | 5/8 | 260 | 80.60 | 14.04 | 37.80 | 54.93 | 66.87 | 85.17 |

perforated API casing pipe with wedge wire wrapped screen jacket

Base pipe with wire wrapped screen jacket consist of two screens or multilayer screens

and the stuffing between the screens. Perforated pipe inside and Johnson type screens/wedge wire screens outside.The base pipe can be made of casing pipes, seamless pipe or welded pipe.

Usually the ID of wire wrapped screen jacket/Johnson type screen equals OD of the perforated base pipe.

Characteristics of perforated casing pipe with wedge wire wrapped screen jacket

1. Pipe based wire wrapped screens consist of two screens or multilayer screen with perforated base pipe.

2. Perforated pipe inside,with perforations wrapped by the outside Johnson type screen/wire wrapped screen.

3. The screen jacket and base pipe are welded together with a length of coupling.

4. The base pipe can be made of seamless pipe or welded pipe, and more often, casing pipes like J55,K55,L80,etc.

5. The connection type can be threaded or plain ends.

Higher filtering accuracy. All-welded wedge wire screens as screen jacket with V opening design makes the filtering accuracy higher, which can control sand better.

2. Excellent strength and resistance to deformation.The base pipe inside, the outside can be protected with the protection jacket added according to requirements, the integrated strength of the perforated base pipe only decreases 2~3% compared with the standard casing/oil tubing, so the pipe based screens have enough integrated strength to resist to the pressure caused by strata. Even if some part of the well screens deformed, the slot of this part will not be widened, which makes higher sand control reliability.

3. More choices. The material of screen jacket can be stainless steel or carbon steel, the material can be chosen as per customers’ requirements.

4. The excellent technique makes the mass production with high efficiency and low cost available.

applications of perforated API casing pipe with wedge wire wrapped screen jacket

Perforated pipes are mainly used for the application of oil reservation layer without much sand or for application of prevents the rock bits dropping off the well bore. This type of product can be used for sand rock and carbonate oil reservation. Is specially used for horizontal oil well. We can drill standard or customized hole size in any number and pattern.