stainless steel Johnson v wire water well screen

November 13, 2017

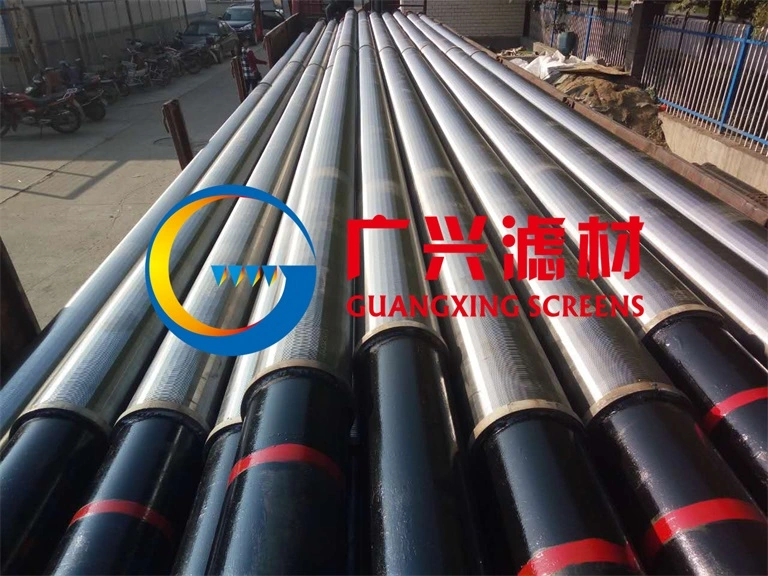

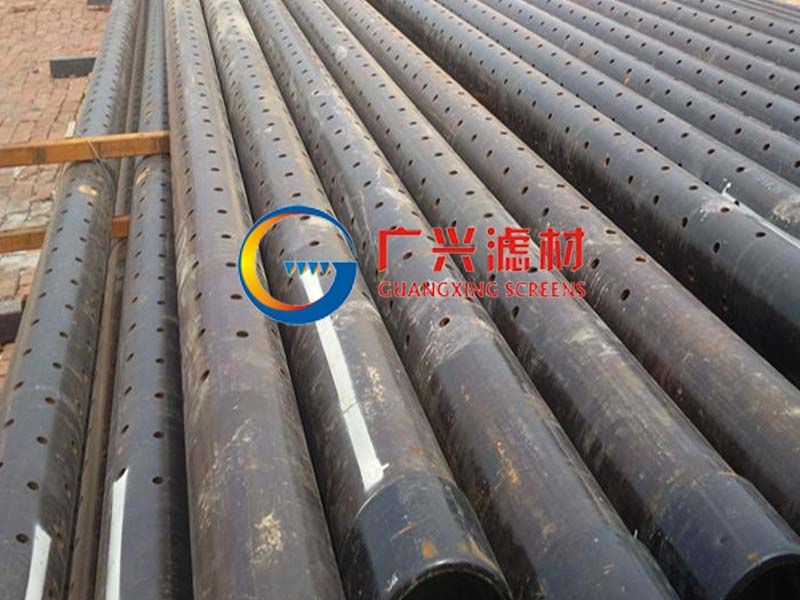

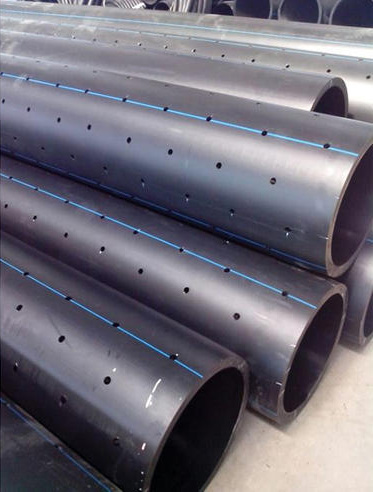

perforated API casing pipe with wedge wire wrapped screen jacket

November 15, 2017Stainless steel is also called corrosion-resistant steel or CRES when the alloy type and grade are not detailed, particularly in the aviation industry. Stainless steel does not readily corrode, rust or stain with water as ordinary steel does, but despite the name it is not fully stain-proof, most notably under low oxygen, high salinity, or poor circulation environments.

Stainless steels contain sufficient chromium to form a passive film of chromium oxide, which prevents further surface corrosion and blocks corrosion from spreading into the metal’s internal structure, and due to the similar size of the steel and oxide molecules they bond very strongly and remain attached to the surface.

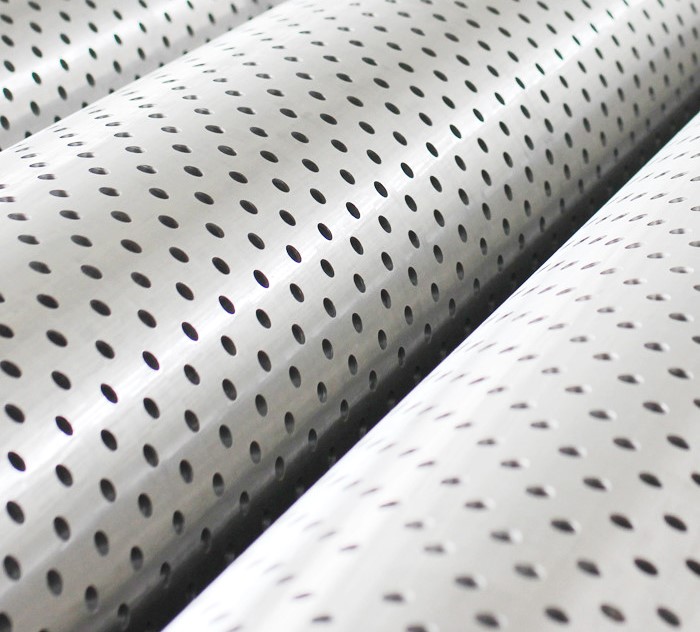

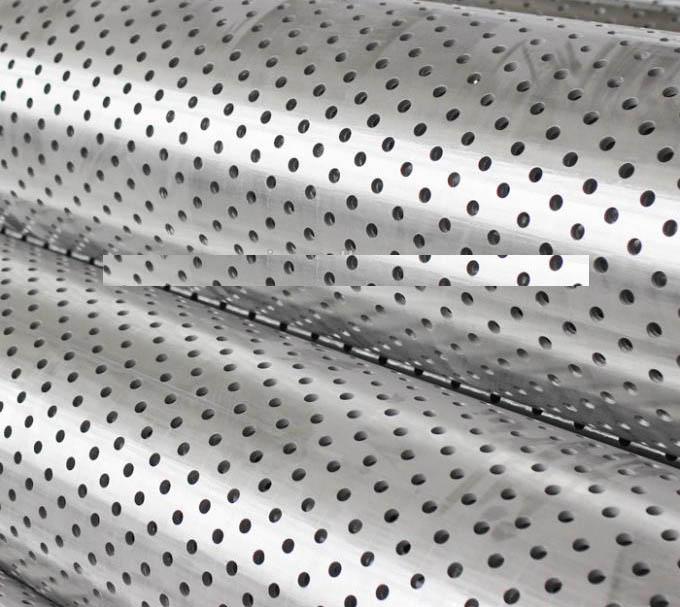

Stainless steel perforated casing pipes are manufactured according to standard API 5CT and 5B, material includes: ASTM SS304/304L, SS316/316L, etc.

Steel grades: J55, K55, L80, N80, C95, P110

Outer diameter range tubing: from 2-3/8 to 4-1/2″ (EUE/NU)

Casing: from 4-1/2 to 20″

Threads: BTC, LTC, STC

Length range: R1, R2, R3

If you interested in our products, feel free to contact with us

We can also produce new VAM/VAM top premium connection

| Outer diameter mm | Ib/ft | Grades | WT | Short | Long | Buttress |

| 114.30 (4 1/2″) | 9.50 | H, J, K | 5.21 | yes | ||

| 10.50 | J, K | 5.69 | yes | yes | ||

| 11.60 | J, K, C, L, N, P | 6.35 | yes | yes | yes | |

| 13.50 | C, L, N, P | 7.37 | yes | yes | ||

| 15.10 | P, Q | 8.56 | yes | yes | ||

| 127.00 (5″) | 11.50 | J, K | 5.59 | yes | ||

| 13.00 | J, K | 6.43 | yes | yes | yes | |

| 15.00 | J, K, C, L, N, P | 7.52 | yes | yes | yes | |

| 18.00 | C, L, N, P, Q | 9.19 | yes | yes | ||

| 21.40 | C, L, N, P, Q | 11.10 | yes | yes | ||

| 23.20 | C, L, N, P, Q | 12.14 | yes | yes | ||

| 24.10 | C, L, N, P, Q | 12.70 | yes | yes | ||

| 139.70 (5 1/2″) | 14.00 | H, J, K | 6.20 | yes | ||

| 15.50 | J, K | 6.98 | yes | yes | yes | |

| 17.00 | J, K, C, L, N, P | 7.72 | yes | yes | yes | |

| 20.00 | C, L, N, P | 9.17 | yes | yes | ||

| 23.00 | C, L, N, P, Q | 10.54 | yes | yes | ||

| 168.28 (6 5/8″) | 20.00 | H, J, K | 7.32 | yes | yes | yes |

| 24.00 | J, K, C, L, N, P | 8.94 | yes | yes | yes | |

| 28.00 | C, L, N, P | 10.59 | yes | yes | ||

| 32.00 | C, L, N, P, Q | 12.06 | yes | yes | ||

| 177.80 (7″) | 20.00 | H, J, K | 6.91 | yes | ||

| 23.00 | J, K, C, L, N | 8.05 | yes | yes | yes | |

| 26.00 | J, K, C, L, N, P | 9.19 | yes | yes | yes | |

| 29.00 | C, L, N, P | 10.36 | yes | yes | ||

| 32.00 | C, L, N, P | 11.51 | yes | yes | ||

| 35.00 | C, L, N, P, Q | 12.65 | yes | yes | ||

| 38.00 | C, L, N, P, Q | 13.72 | yes | yes | ||

| 193.68 (7 5/8″) | 24.00 | H | 7.62 | yes | ||

| 26.40 | J, K, C, L, N | 8.33 | yes | yes | yes | |

| 29.70 | C, L, N, P | 9.52 | yes | yes | ||

| 33.70 | C, L, N, P | 10.92 | yes | yes | ||

| 39.00 | C, L, N, P, Q | 12.70 | yes | yes | ||

| 42.80 | C, L, N, P, Q | 14.27 | yes | yes | ||

| 45.30 | C, L, N, P, Q | 15.11 | yes | yes | ||

| 47.10 | C, L, N, P, Q | 15.88 | yes | yes | ||

| 196.85 (7 3/4″) | 46.10 | C, L, N, P, Q | 15.11 | |||

| 219.08 (8 5/8″) | 24.00 | J, K | 6.71 | yes | ||

| 28.00 | H | 7.72 | yes | |||

| 32.00 | H, J, K | 8.94 | yes | yes | yes | |

| 36.00 | J, K, C, L, N | 10.16 | yes | yes | yes | |

| 40.00 | C, L, N, P | 11.43 | yes | yes | ||

| 44.00 | C, L, N, P | 12.70 | yes | yes | ||

| 49.00 | C, L, N, P, Q | 14.15 | yes | yes | ||

| 244.48 (9 5/8″) | 32.30 | H | 7.92 | yes | ||

| 36.00 | H, J, K | 8.94 | yes | yes | yes | |

| 40.00 | J, K, C, L, N | 10.03 | yes | yes | ||

| 43.50 | C, L, N, P | 11.05 | yes | yes | ||

| 47.00 | C, L, N, P, Q | 11.99 | yes | yes | ||

| 53.50 | C, L, N, P, Q | 13.84 | yes | yes | ||

| 273.05 (10 3/4″) | 32.75 | H | 7.09 | yes | ||

| 40.50 | H, J, K | 8.89 | yes | yes | ||

| 45.50 | J, K | 10.16 | yes | yes | ||

| 51.00 | J, K, C, L, N, P | 11.43 | yes | yes | ||

| 55.50 | C, L, N, P | 12.57 | yes | yes | ||

| 60.70 | P, Q | 13.84 | yes | yes | ||

| 65.70 | P, Q | 15.11 | yes | yes | ||

| 298.45 (11 3/4″) | 42.00 | H | 8.46 | yes | ||

| 47.00 | J, K, M | 9.53 | yes | yes | ||

| 54.00 | J, K, M | 11.05 | yes | yes | ||

| 60.00 | J, K, M, L, N, C, P, Q | 12.42 | yes | yes | ||

| 339.7(13 3/8″) | 48.00 | H | 8.38 | yes | ||

| 54.50 | J, K | 9.65 | yes | yes | ||

| 61.00 | J, K | 10.92 | yes | yes | ||

| 68.00 | J, K, C, L, N, P | 12.19 | yes | yes | ||

| 72.00 | C, L, N, P, Q | 13.06 | yes | yes | ||

| 406.40 (16″) | 65.00 | H | 9.53 | yes | ||

| 75.00 | J, K, M | 11.13 | yes | yes | ||

| 84.00 | J, K, M | 12.57 | yes | yes | ||

| 473.08 (18 5/8″) | 87.50 | H, J, K, M | 11.05 | yes | yes | yes |

| 508.00 (20″) | 94.00 | H, J, K | 11.13 | yes | yes | yes |

| 106.50 | J, K | 12.70 | yes | yes | yes | |

| 133.00 | J, K | 16.13 | yes | yes | yes |

Uses: used in filter of automobiles internal-combustion engine, sieving of mine, Medicine, grain, sound insulation of room, ventilate of grain depot, etc.

Filter tube material : stainless steel 304 316 316l used for water system

Layer: one layer or two layer or three layer

Technical: perforated square hole or round hole or other hole size , then welded specifications base on you.

1. continuous slot wire wrap screen, pipe base screen, perforated pipe, slotted pipe

2. API casing pipe and tube

3. stainless steel pipe

3. drilling rig, mud pump, air compressor and accessories

4. test instrument

5. welding machine

6. food and beverage

7. industrial additives