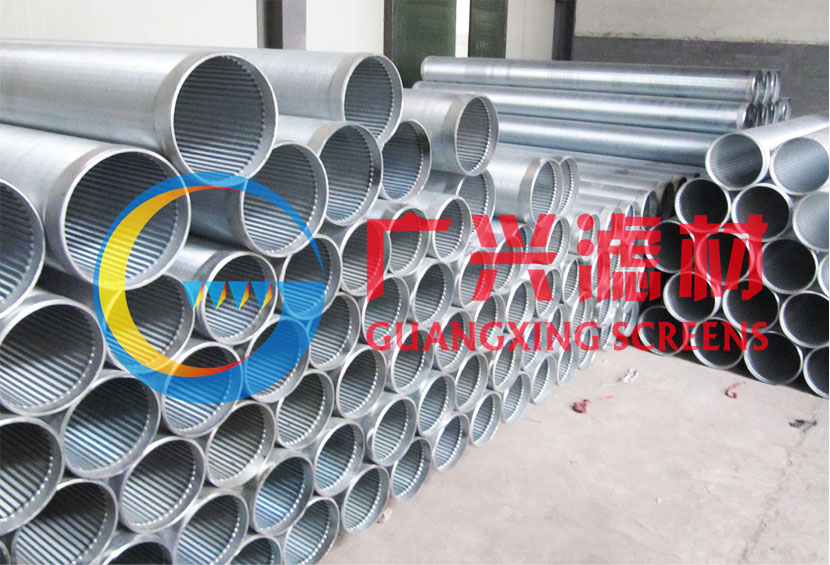

Water Well Screen For Groundwater

January 9, 2018

Well Water Filter Pipe – Removing Sand And Sediment From Well Water

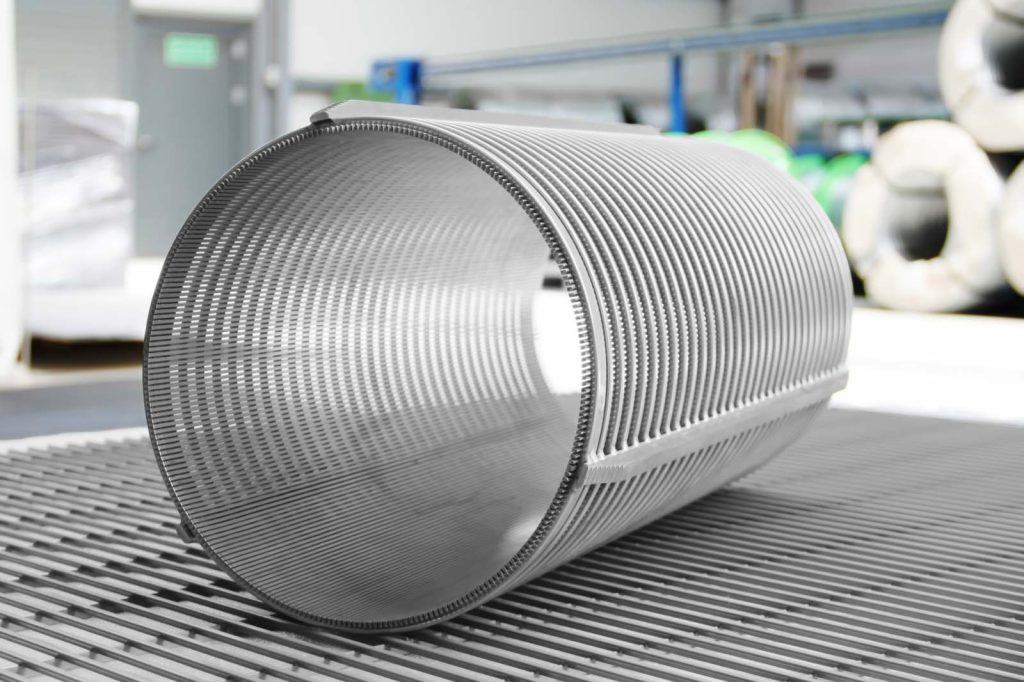

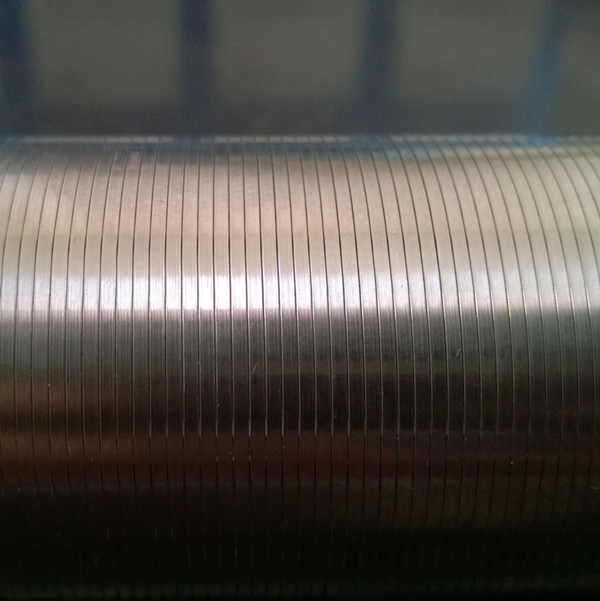

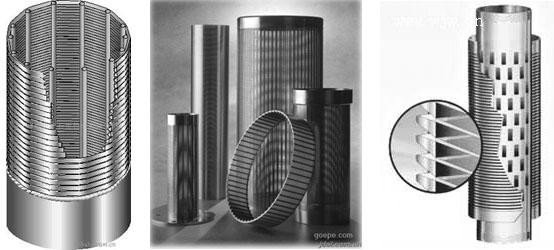

January 21, 2018Wedge wire is known as profile wire screen, V- wire screen, and wedge wire screen. Why Wedge Wire?

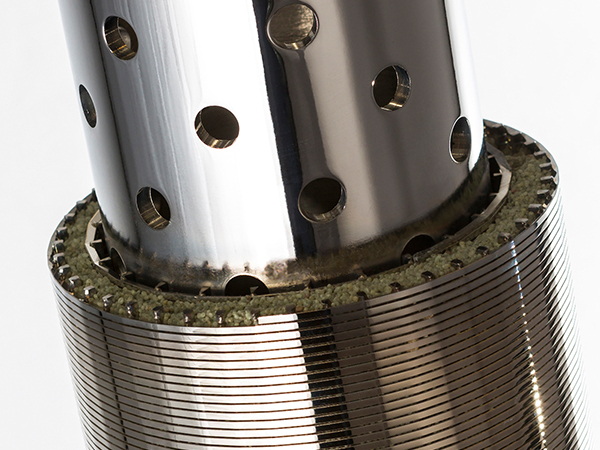

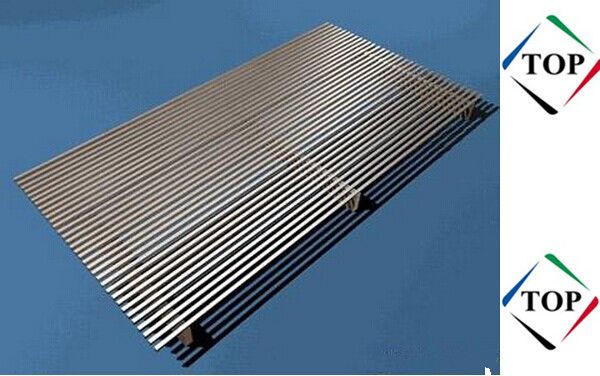

Wedge-Wire products are manufactured by an exclusive process of continuously welding an outer profile wire circumferentially in a helix pattern to a series of longitudinal support rods.It can mead: Conical strainers , Strainer baskets , pressure cylindrical screens , traps , nozzles , designed fabricated parts

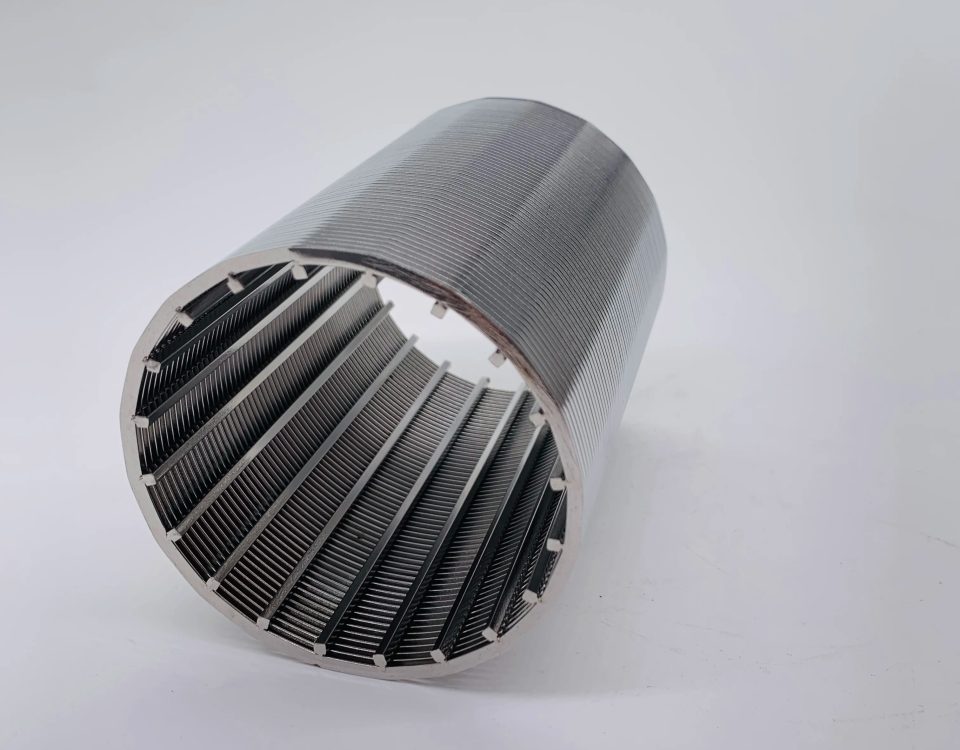

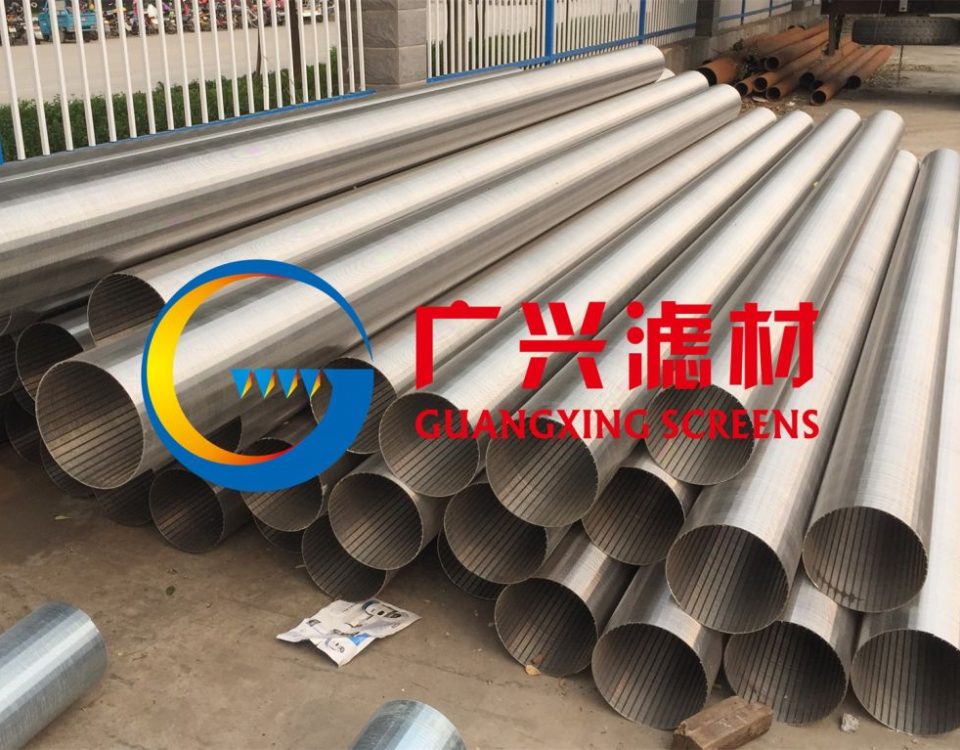

Continuous slot screens made of V shape wire wrapped around a series of vertical rods. This allows the most inlet area and higher productions rates.

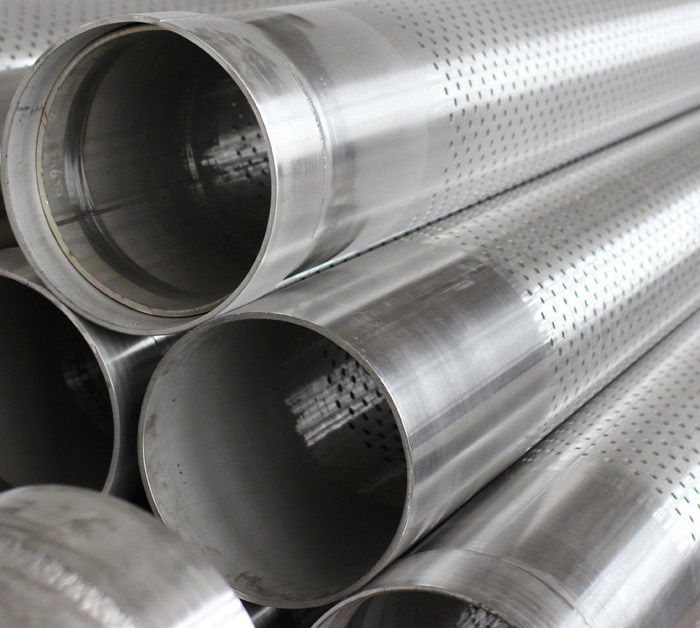

Sand can represent a major obstacle to oil and gas well production. When produced with hydrocarbons and water, sand represents a costly problem. Hence, sand control is vital to the overall completion process in many reservoirs.

design and versatility of wedge wire products makes itself an ideal component for fluid treatment industry.

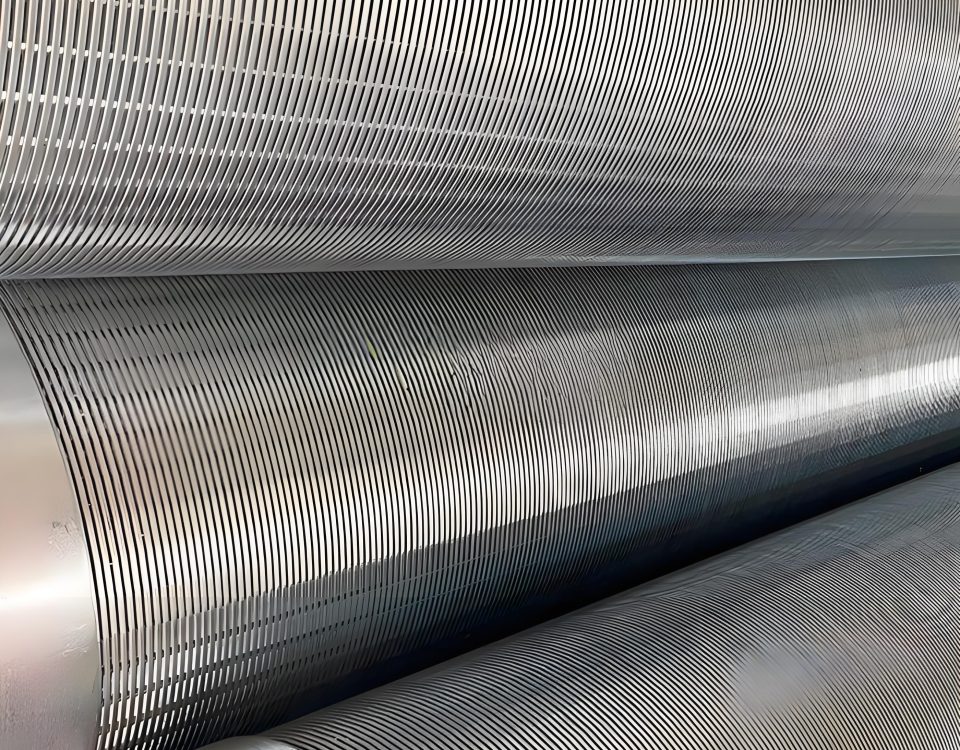

Its characteristic features are accurate production and precise gap sizes, which result in the ability to carry heavy loads. The slotted screen is also characterized by low possibility of blanking, perfectly smooth surface and high open surface ratio. As a result of modern technology of welding, different wires may be used, various slots in one wedge wire screen, as well as different distances between supporting wires can be created.

well Screens · Self-cleaning Screens · Polyurethane Screens · Rubber Screens · Perforated Metal Plate · Electro-welded Screens · Wedge Wire Screens · Vibrating Finger Screens · Other Products and Accessories · Crusher wear and spare parts. Contact information

• Strength and quality of material make the screens highly resistant to corrosion and impact damage

• Every intersection of wrap wire and support bar is resistance welded

Lower Maintenance Cost

• Sturdy construction using highest quality materials result in a longer lasting screen that requres little or no maintenance

• Profile and slot construstion helps eliminate screen blinding and clogging

Custom Design

• Screens are manufactured to suit your individual job requirements

Well screens (filtering devices) are installed in the water bearing formations, allowing water to move into the well, while keeping out gravel and sand. The most popular filtering devices for water wells are continuous slot (wire-wrapped) screens and perforated liners.

GUANGXING COMPANY Wedge Wire Screens & Filtration Devices are among the best in the industry!