V-Shaped Wire Screen Hydraulic Advantage

September 30, 2025

Stainless Steel Pipe Base Screens Comprehensive Guide

October 10, 2025The Apex of Downhole Reliability: Stainless Steel Pipe Base Wire Wrapped Well Screens

1. Introduction: Securing Productivity with Integrated Sand Control

In the highly challenging and resource-intensive environment of hydrocarbon and water extraction, the foundation of wellbore integrity and sustained production lies in effective **sand control**. Uncontrolled migration of formation sand can lead to catastrophic equipment failure, premature well abandonment, and significant operational costs. To mitigate this pervasive risk, the industry relies on specialized filtration devices. Among the array of available technologies, the **Stainless Steel Pipe Base Wire Wrapped Well Screen** stands as the definitive solution for applications demanding the utmost in mechanical strength, filtration accuracy, and corrosion resistance.

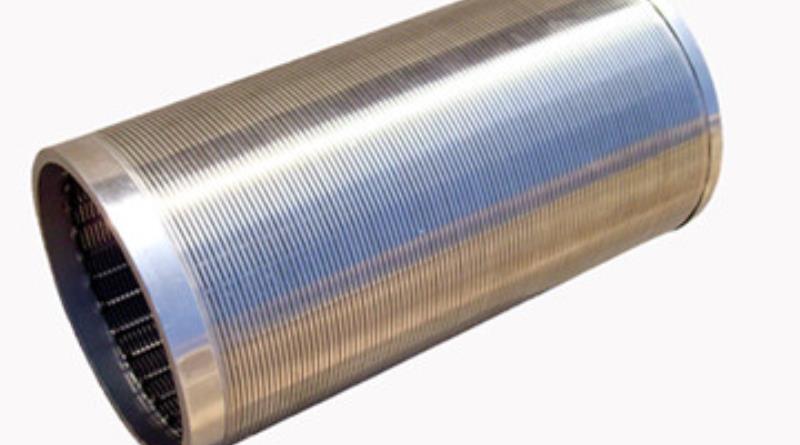

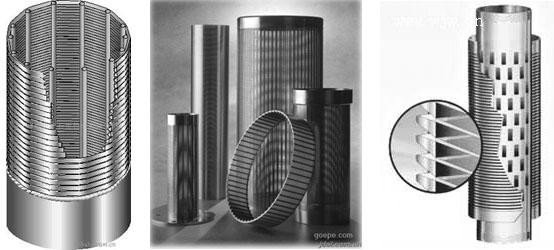

This product is not merely a filter; it is a meticulously engineered composite structural element. By integrating a high-strength perforated **API casing or tubing base pipe** with an external, precision-welded **wedge wire jacket**, these screens achieve a symbiotic relationship between strength and filtration efficiency. This design fundamentally addresses the historical trade-off between the mechanical robustness required to survive deep wellbore installation and formation pressures, and the hydraulic requirements necessary for maximizing fluid flow and minimizing plugging.

Manufactured from corrosion-resistant alloys, specifically the highly durable **Stainless Steel 304** and the superior, molybdenum-bearing **316L**, our pipe base screens are engineered for longevity and performance in aggressive downhole fluids—including high \(\text{H}_2\text{S}\), \(\text{CO}_2\), and chloride environments. This comprehensive technical review will dissect the critical design, material science, manufacturing precision, and operational advantages of our **Pipe Based Well Screens**, illustrating why their unparalleled strength, reliability, and hydraulic characteristics make them the essential choice for securing high-value, long-term wellbore productivity. We will detail the specific engineering parameters and material properties that confirm the superior performance of these **Double Layer Wire Wrapped Screens** over conventional filtration methods.

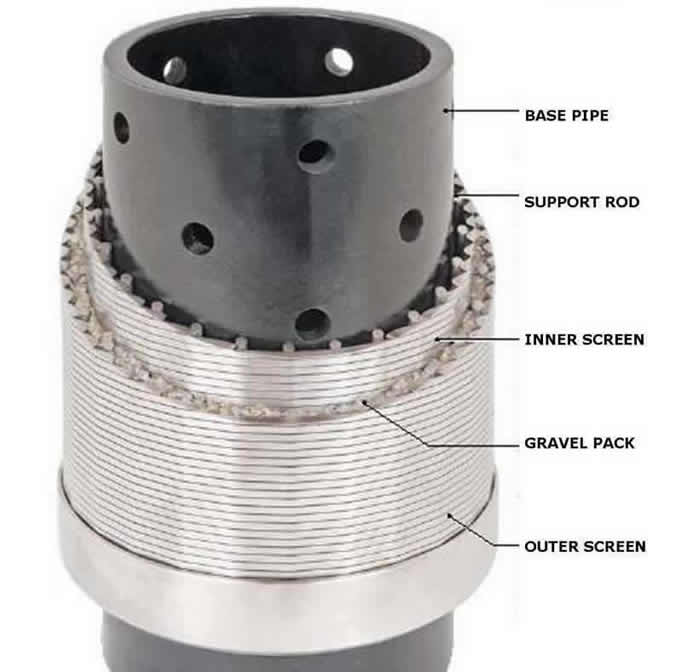

2. Core Design and Construction: The Anatomy of a High-Integrity Screen

The effectiveness of the pipe-based screen rests entirely on the sophisticated integration of its three primary components. This **”double layer”** approach provides a degree of redundancy and mechanical integrity unmatched by single-layer screens.

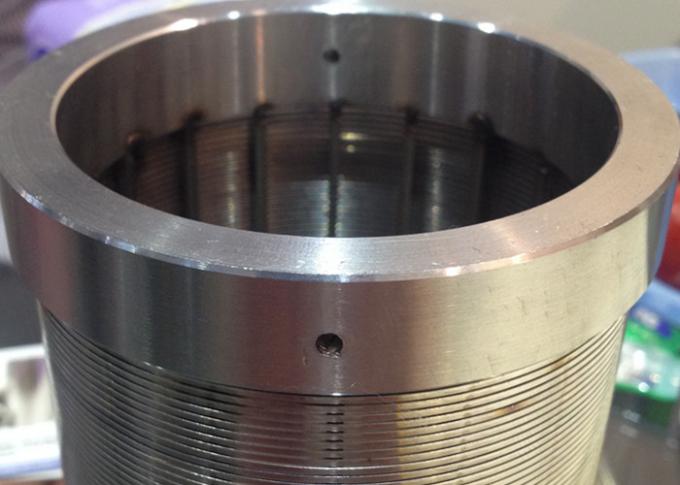

2.1. The Base Pipe: Structural Backbone and API Compliance

The internal core of the assembly is the **Base Pipe**, which provides the vast majority of the screen’s mechanical strength, including its critical resistance to tension, compression, collapse, and burst.

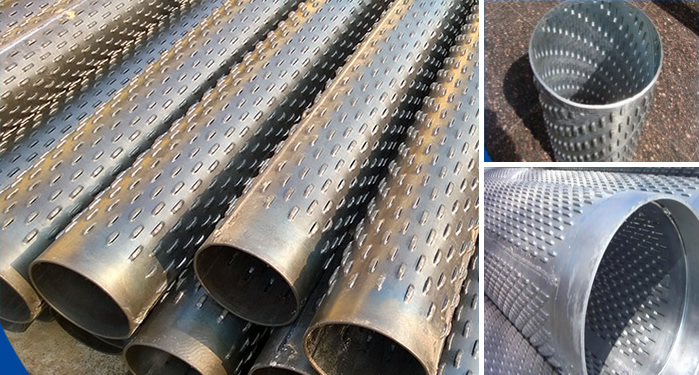

- Material and Standard: The base pipe is typically a standard API casing or tubing, often compliant with **API Spec 5CT** requirements. While stainless steel (304 or 316L) base pipe can be specified for extreme corrosion, **carbon steel API grades** (such as J55, K55, N80, or P110) are frequently used due to their superior integrated strength and cost-effectiveness, especially when the outer wedge wire jacket provides the necessary corrosion barrier.

- Perforation or Slotting: The pipe is internally prepared with either precisely **slotted or perforated holes**. These openings are designed to maximize the open area for fluid flow while ensuring that the residual strength of the pipe is retained. The mechanical feature provided by the customer highlights the fact that the integrated strength of the perforated base pipe only decreases by a mere **2% to 3%** compared to the standard casing. This negligible reduction confirms that the pipe-based screen maintains essentially the full structural integrity of the chosen API casing grade, a decisive advantage in deep, high-pressure wells.

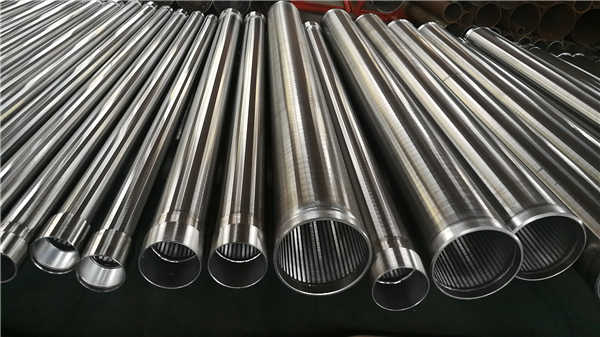

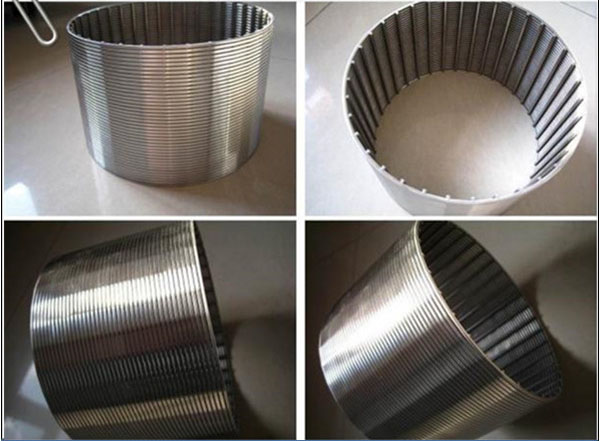

2.2. The Wedge Wire Jacket: Filtration Precision

The external component is the **All-Welded Wedge Wire Screen**, the filtration medium itself. It is the primary layer responsible for controlling the flow of formation solids (sand) while allowing reservoir fluids (oil, gas, water) to enter the wellbore.

- Vee-Shaped Opening: The defining feature is the \(\text{vee}\)-shaped wire profile, which creates a precise, fixed slot opening. The slot widens inwardly toward the base pipe. This design is fundamentally **anti-plugging**; any sand particle that successfully passes through the narrowest part of the slot opening is free to continue flowing through the rest of the screen and into the wellbore. This self-cleaning characteristic drastically reduces the chance of fines accumulating and blinding the screen surface, thereby sustaining higher hydraulic efficiency over time.

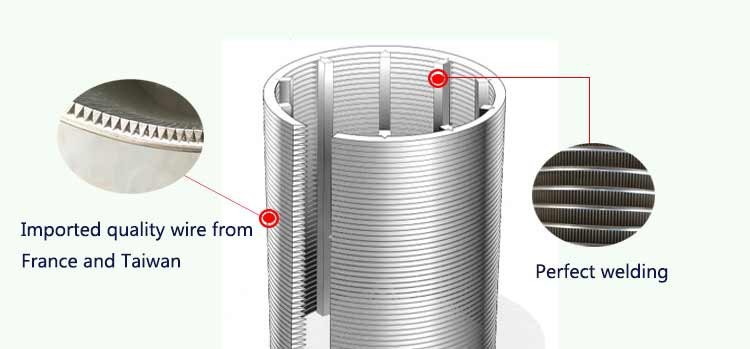

- All-Welded Construction: The profile wire is resistance-welded to the support rods at every intersection. This creates a monolithic, extremely rigid filtration jacket that cannot unravel, warp, or vibrate loose under production loads.

2.3. Supporting Rods: The Integration Element

The two layers—the base pipe and the wedge wire jacket—are mechanically integrated using **Supporting Rods**. These rods, usually circumferentially placed and longitudinally continuous, are welded to the outer surface of the perforated base pipe and then, in turn, welded to the inner surface of the wedge wire jacket. This welding sequence creates a continuous, high-strength annular space, ensuring:

- Load Distribution: The rods distribute axial and torsional loads between the pipe and the jacket, preventing any relative movement.

- Annular Flow: The spacing between the rods provides an unobstructed annular space for the filtered fluid to travel along the screen length and access the perforations in the base pipe, minimizing pressure drop.

The term **Double Layer Wire Wrapped Screens** can refer to the use of an outer protective shroud over the filtration jacket, or more commonly in the context of pipe-based screens, the integrated system of the base pipe acting as the inner structural layer and the wedge wire jacket acting as the outer filtration layer.

3. Materials Science Focus: Stainless Steel 304 and 316L Excellence

The longevity and reliability of a well screen in the corrosive downhole environment are inextricably linked to its material composition. Our selection of **Stainless Steel (SS) 304** and **SS 316L** offers a calculated balance of cost, strength, and corrosion resistance for the external wedge wire jacket.

3.1. SS 304: The Workhorse of Corrosion Resistance

Stainless Steel 304, an austenitic alloy, is the standard choice for general service well screens where formation fluids exhibit moderate salinity and low concentrations of corrosive gases (\(\text{H}_2\text{S}\) and \(\text{CO}_2\)).

- Composition: \(\text{SS } 304\) derives its fundamental corrosion resistance from a high **chromium (\(\text{Cr}\))** content (typically 18-20%) and a moderate **nickel (\(\text{Ni}\))** content (8-10.5%). The \(\text{Cr}\) forms a stable, passive oxide film on the surface, which is self-healing and protects the underlying steel from attack.

- Application: It is ideal for fresh water wells, moderate-salinity water injection wells, and oil/gas wells with known mild corrosive conditions. Its strength and ductility make it excellent for the required all-welded wedge wire manufacturing process.

3.2. SS 316L: Enhanced Durability with Molybdenum

For demanding environments—especially deep reservoirs with high chloride concentrations, elevated temperatures, and significant \(\text{CO}_2\) or trace \(\text{H}_2\text{S}\)—**SS 316L** is the material of choice. The “\(\text{L}\)” denotes low carbon content (maximum 0.03%), which is critically important for weldability, minimizing the risk of sensitization and **intergranular corrosion** in the heat-affected zone (HAZ) of the welds.

- Molybdenum (Mo) Advantage: The distinguishing feature of \(\text{SS } 316\text{L}\) is the addition of $2\%$ to $3\%$ **molybdenum (\(\text{Mo}\))**. Molybdenum significantly enhances the stability of the passive film and provides vastly superior resistance to **pitting** and **crevice corrosion** in chloride-rich brines. Pitting is the most common failure mode for stainless steel in chloride environments, and \(\text{Mo}\) acts as the primary deterrent against this localized attack.

- Application: \(\text{SS } 316\text{L}\) is the benchmark for oil and gas production wells, geothermal wells, and high-salinity water wells where screen longevity and resistance to localized corrosion are paramount.

3.3. Chemical Composition Table

The precise control of these elements is verified through material test reports, ensuring the screens deliver the expected metallurgical performance required by the chosen grade.

| Element | Stainless Steel 304 (Weight %) | Stainless Steel 316L (Weight %) | Role in Corrosion Resistance |

|---|---|---|---|

| Carbon (C) max. | 0.08 | 0.03 | Low C (‘L’ grade) prevents sensitization and intergranular corrosion during welding. |

| Chromium (Cr) | 18.0 – 20.0 | 16.0 – 18.0 | Primary element for passive film formation; confers general corrosion resistance. |

| Nickel (Ni) | 8.0 – 10.5 | 10.0 – 14.0 | Stabilizes the austenitic structure; improves toughness and ductility. |

| Molybdenum (Mo) | – | 2.0 – 3.0 | Crucial for resistance to pitting and crevice corrosion in chloride environments. |

| Manganese (Mn) max. | 2.0 | 2.0 | Deoxidizer and sulfur fixative. |

| Phosphorus (P) max. | 0.045 | 0.045 | Impurity; controlled to maintain ductility. |

| Sulfur (S) max. | 0.030 | 0.030 | Impurity; controlled to maintain weld integrity. |

—

4. Manufacturing Precision: Forging a Structural Filter

The manufacturing process for pipe based well screens is a complex fusion of precision machining (for the base pipe) and advanced welding technology (for the jacket assembly and integration). The final product’s high performance is a direct result of tightly controlled tolerances and rigorous quality checks at every stage.

4.1. Base Pipe Preparation and Collapse Resistance

The base pipe selection dictates the structural limit of the entire screen assembly. We ensure the **API 5CT** casing used is subjected to non-destructive testing (NDT) to verify its integrity before modification. The perforation or slotting process is precisely engineered:

- Pattern Design: The pattern of openings (staggered or inline) is calculated to balance the maximization of open area (for fluid entry) with the preservation of the casing’s original collapse and burst strength. As noted, the superior design ensures this strength reduction is minimal (\(2\% \text{ to } 3\%\)).

- Burr and Debris Removal: After machining, all internal and external surfaces are meticulously cleaned to remove metal burrs, which could interfere with subsequent welding, or debris, which could lead to sand-trapping and plugging during operation.

4.2. All-Welded Wedge Wire Assembly

The filtration jacket is manufactured independently and then integrated. The core technology is the continuous welding of the trapezoidal (wedge) profile wires onto the support rods.

- Automated Welding: This is achieved using specialized, high-precision automated welding machines. The process is typically continuous resistance welding, which melts the wires and rods at their point of intersection. This creates a homogeneous, high-strength metallic bond without the use of filler material, maintaining the integrity of the stainless steel grade (304 or 316L).

- Slot Tolerance: The separation between the profile wires defines the **slot size**, the critical parameter for sand control. Our advanced wrapping and welding machinery maintains slot widths—which can be as small as \(0.004\) inches (100 microns)—with micron-level accuracy along the entire length of the screen section. This dimensional consistency is fundamental to reliable sand exclusion.

4.3. Final Integration and Quality Assurance

The integration of the pre-fabricated jacket onto the base pipe is the final step, involving welding the supporting rods to the perforated casing. This process must be carefully controlled to prevent heat distortion in the base pipe or degradation of the wedge wire jacket.

- Hydrostatic Testing: All finished pipe based screens are subjected to rigorous quality control, including dimensional checks and, often, **hydrostatic pressure testing** of the base pipe. Though the hydrostatic test may be waived for screens, our internal standards frequently necessitate its performance to confirm the integrity of the casing and the structural competence of the base pipe perforations under pressure.

- Weld Integrity NDT: The final welds that integrate the jacket to the base pipe are often checked using non-destructive testing (NDT) techniques, such as liquid penetrant inspection (PT) or magnetic particle inspection (MT) for carbon steel, or ultrasonic testing (UT) for highly critical applications, to ensure there are no cracks or lack of fusion that could compromise the screen’s structural reliability.

—

5. Mechanical Integrity and Performance: Strength Beyond Filtration

The paramount feature highlighted by our product description is the superior mechanical strength derived from the pipe-based design. In deep wells, the screen must withstand massive forces during running, setting, and long-term production.

5.1. Resistance to Collapse and Burst

The limiting factor for the screen’s operational depth and pressure rating is the strength of the **API casing base pipe**. The pipe based screen’s primary mechanical benefit is the retention of nearly **\(97\%\) to \(98\%\) of the original casing strength**.

- Collapse Resistance: During installation or under reservoir depletion, the screen must resist external pressure from the formation and wellbore fluids. A stand-alone screen relies solely on the thin profile wire structure for collapse resistance, which is inherently limited. The pipe-based screen, conversely, relies on the full wall thickness of the inner API casing, providing predictable and immense collapse strength based on the selected API grade (J55, N80, etc.).

- Axial and Torsional Strength: When running the screen into the hole, the assembly is subjected to high axial tension (due to weight) and torsional loads (due to rotation). The API-grade base pipe ensures that the screen string can be safely run to any depth that the standard casing could reach, eliminating the depth limitations often associated with independent screen types.

5.2. Resistance to Deformation and Sand Control Reliability

The structural feature of the pipe base screen that most directly impacts sand control is its resistance to localized deformation.

- No Slot Widening: Even if extreme formation pressure causes localized deformation or slight collapse of the base pipe, the presence of the rigid internal base pipe prevents the outer wedge wire jacket from bowing inward or experiencing the kind of catastrophic localized failure that would widen the slot size. This is a critical distinction: the pipe base screen ensures that the **slot size integrity is maintained** even if the pipe structure is marginally compromised, thereby guaranteeing the continuous, reliable exclusion of sand. This ensures **higher sand control reliability**, as stated in the product features.

- Integrated Strength Calculation: For an engineer, this translates into predictable performance. The calculation for the maximum allowable external pressure (\(\text{P}_{\text{max}}\)) for the screen is defined by the collapse pressure of the chosen API casing grade, not the filtration medium.

5.3. Mechanical Property Benchmarks

The mechanical integrity is defined by the base pipe (\(\text{API } 5\text{CT}\)) and the wedge wire material (\(\text{SS } 304/316\text{L}\)). The table below lists the typical mechanical properties for the wedge wire material and common base pipe reference grades.

| Material Component | Minimum Yield Strength (\(R_{p0.2}\)) (\(\text{MPa}\) / psi) | Minimum Tensile Strength (\(R_{m}\)) (\(\text{MPa}\) / psi) | Minimum Elongation (%) |

|---|---|---|---|

| SS 304/316L (Wedge Wire) | \(205\) / \(30,000\) | \(515\) / \(75,000\) | 40 |

| API 5CT Grade J55 (Base Pipe) | \(379\) / \(55,000\) | \(517\) / \(75,000\) | – |

| API 5CT Grade N80 (Base Pipe) | \(552\) / \(80,000\) | \(689\) / \(100,000\) | – |

The combined structure leverages the high mechanical values of the API casing with the inherent corrosion resistance and ductility of the stainless steel jacket, creating a uniquely robust composite screen.

—

6. Hydraulic Efficiency and Productivity: The \(\text{Vee}\)-Slot Advantage

The hydraulic performance of a well screen is determined by its **open area** and its ability to resist blinding (plugging). The \(\text{vee}\)-slot design of the all-welded wedge wire jacket is fundamentally optimized for fluid flow and longevity.

6.1. The \(\text{Vee}\)-Slot: Non-Plugging Flow Dynamics

The trapezoidal profile wire creates a slot opening that is significantly wider on the inside (facing the base pipe) than on the outside (facing the formation). This critical geometry ensures that:

- Particle Clearance: A particle that enters the slot will not become wedged. Instead, it is either small enough to pass completely through or large enough to be immediately stopped at the outside edge. This principle eliminates the primary cause of screen plugging: **bridging** within the slot opening.

- Increased Flow Area: For a given slot size, the \(\text{vee}\)-wire construction provides a larger percentage of open area per unit length compared to conventional slotted pipe or mesh screens. This translates directly to reduced pressure drop (\(\Delta P\)) across the screen, which is essential for maximizing fluid entry.

6.2. The Productivity Paradox: Smaller Slot, Higher Output

The product feature notes that a **smaller slot will increase the oil and gas production**. This seemingly counter-intuitive statement is a cornerstone of modern sand control theory, directly related to minimizing the **skin effect**—the localized damage or flow impedance near the wellbore.

- Optimal Skin Effect: By using a smaller, more accurately controlled slot size (often sized to retain the smallest \(10\%\) to \(40\%\) of the formation grain size, or \(d_{10}\) to \(d_{40}\)), the screen helps to stabilize the native formation immediately adjacent to the wellbore. This stabilization minimizes the turbulence and fine particle movement that typically cause formation collapse, fines migration, and the resulting high skin factor (flow resistance).

- Formation Stability: The small slot size encourages the formation of a **stable, permeable filter cake** on the screen’s exterior, composed of the coarse formation particles. This natural filter medium has higher intrinsic permeability than a gravel pack placed against a large slot opening. By creating a stable, minimal-damage zone, the screen maximizes the *effective* hydraulic conductivity of the entire near-wellbore region, leading to sustained, higher production rates and the avoidance of high-rate pressure loss.

6.3. Calculating Open Area

The open area (\(\text{A}_{\text{open}}\)) is calculated based on the slot width (\(\text{W}_{\text{slot}}\)), the number of slots per length, and the dimensions of the profile wire. Maximizing \(\text{A}_{\text{open}}\) is a primary design goal, typically ranging from \(15\%\) to over \(35\%\) for wedge wire screens. High \(\text{A}_{\text{open}}\) ensures that fluid enters the screen with low velocity, minimizing pressure drop and the tendency for fines to plug the screen surface due to localized high-speed flow.

—

7. Superior Sand Control and Filtration Theory

The effectiveness of the pipe base screen in sand control is rooted in its robust design and its interaction with the reservoir formation, whether it is an open hole or a gravel-packed completion.

7.1. Function in Gravel Pack Completions

In the most demanding applications, the pipe base screen serves as the conduit within a **gravel pack completion**. Here, the screen’s primary function is structural support and retention of the artificial, highly permeable gravel pack material:

- Gravel Retention: The screen’s slot size is selected to retain \(90\%\) or more of the gravel pack particle size (typically \(d_{90}\)).

- Structural Integrity: This is where the strength of the pipe base design is critical. The screen must withstand the weight and forces of the gravel slurry emplacement and the differential pressure across the pack during production. The guaranteed **non-widening slot size** (due to the rigid base pipe) ensures that the expensive, carefully sized gravel pack material remains in place, preventing its mixing with formation sand and subsequent screen failure.

7.2. Function in Stand-Alone Screen (SAS) Applications

In competent formations, the pipe base screen is run without an artificial gravel pack. The screen then relies on its precise slot size and deformation resistance to create the stable filter cake described in Section 6.

- Controlled Flow: The combination of the rigid external \(\text{SS}\) jacket and the strong internal \(\text{API}\) base pipe minimizes the risk of screen washouts or catastrophic failure from turbulent fluid entry, especially in long horizontal sections where localized high velocity spots can be problematic. The rigid structure ensures the integrity of the filter cake remains constant along the entire production interval.

7.3. Resistance to \(\text{H}_2\text{S}/\text{CO}_2\) Stress Corrosion

Beyond general corrosion, high-strength tubular goods are susceptible to **Sulfide Stress Cracking (SSC)** from \(\text{H}_2\text{S}\) and **Stress Corrosion Cracking (SCC)** from \(\text{CO}_2\)/chlorides. By utilizing \(\text{SS } 316\text{L}\) (low carbon, molybdenum) for the exterior jacket and often specifying corrosion-resistant alloy (CRA) or appropriate N80 / P110 variants for the base pipe, the entire assembly’s resistance to these forms of localized, stress-induced cracking is maximized, ensuring a design life that meets or exceeds the reservoir’s production life.

—

8. Quality Control and API Casing Compliance

To function reliably at depth, the pipe base screen must maintain the certification and strength standards of the industry’s most rigorous specifications.

8.1. Adherence to API 5CT and API 10D

The base pipe is the single most important structural element and must be traceable to its original **API 5CT** certification. This ensures compliance with standard metallurgical, dimensional, and mechanical property requirements (e.g., drift test, yield strength verification). By starting with API certified material, the final screen inherits a verified level of collapse and burst resistance.

- Traceability: Every screen joint is manufactured with full material traceability, linking the final product back to the mill heat number and the original \(\text{API}\) Certificate of Conformance. This is non-negotiable for critical downhole tools.

8.2. Dimensional Tolerance and \(\text{ISO}\) Standards

The screens are manufactured under a robust quality management system, typically compliant with **ISO 9001**. Key dimensional checks include:

- Slot Tolerance: Verification that the slot width is maintained within the specified micron tolerance using high-magnification optical comparators.

- Pipe End Preparation: The threads (if applicable) or bevels (for welding) on the base pipe must conform to \(\text{API}\) specifications to ensure seamless integration with the rest of the casing string.

- Straightness and Concentricity: The wedge wire jacket must be perfectly concentric with the base pipe to prevent eccentric loading and maintain a uniform flow area, which is verified using precision jigs and instruments.

—

9. Application Versatility and Selection Criteria

The pipe base screen’s inherent strength and design flexibility make it suitable for a wide array of downhole applications, particularly where depth, high pressure, or corrosive fluids limit the use of less robust screens.

9.1. Versatile Application Spectrum

- Oil and Gas Production: High-rate oil and gas wells, especially those completed in unconsolidated or weakly consolidated sandstone reservoirs. Essential for long **horizontal wells** where running weight and frictional drag require maximum axial strength.

- Water Wells: Deep water wells where the screen must withstand massive formation pressure during pumping and be resistant to corrosion from aggressive groundwater chemistry.

- Injection Wells: Used in water or \(\text{CO}_2\) injection wells, where the screen protects the injection pumps from particulates and must withstand the high pressures inherent in deep injection programs.

- Remedial and Workover Operations: Their high strength allows them to be used as robust liner completions in unstable boreholes.

9.2. Key Selection Criteria

The engineer’s selection process hinges on the synergy between the base pipe and the filtration jacket:

- Slot Size: Determined by the formation particle size distribution (\(\text{PSD}\)) or the required gravel pack particle size, ranging typically from \(0.004\) in to \(0.080\) in.

- Material Grade: The \(\text{SS } 304\) vs. \(\text{SS } 316\text{L}\) decision is dictated by the \(\text{H}_2\text{S}\), \(\text{CO}_2\), and chloride content of the reservoir fluid. The base pipe grade is selected based on the well’s pressure profile (\(\text{P}_{\text{collapse}}\), \(\text{P}_{\text{burst}}\)).

- Base Pipe Dimension: Selected to match the casing or liner size (e.g., \(4\frac{1}{2}\) in, \(5\frac{1}{2}\) in, \(7\) in \(\text{OD}\)) and wall thickness (\(\text{WT}\)) required for the well design.

9.3. Technical Parameters and Dimensions

The following table outlines the typical range of dimensions and features available for our pipe based well screens, confirming the wide array of customization possible under the robust \(\text{API } 5\text{CT}\) framework.

| Parameter | Typical Range | Units | Notes on Customization |

|---|---|---|---|

| Outer Diameter (OD) | \(4\) to \(13\frac{3}{8}\) | inches | Matches standard \(\text{API}\) casing sizes for seamless integration. |

| Base Pipe Weight | \(9.5\) to \(68.0\) | \(\text{lb}/\text{ft}\) | Chosen based on \(\text{API}\) grade for collapse/burst resistance. |

| Wall Thickness (WT) | \(0.205\) to \(0.595\) | inches | Dictated by the required structural integrity and \(\text{API}\) grade. |

| Slot Size | \(0.004\) to \(0.080\) | inches (in) | Critical parameter based on \(\text{PSD}\) or gravel pack size; maintained with micron accuracy. |

| Base Pipe Open Area | \(3\%\) to \(10\%\) | Percentage | Engineered to minimize strength reduction (\(2\% \text{ to } 3\%\)) while allowing sufficient flow. |

| Screen Jacket Open Area | \(15\%\) to \(35\%\) | Percentage | Directly influences the hydraulic efficiency (\(\Delta P\)) of the filter medium. |

| Standard Length | \(10\) to \(40\) | \(\text{ft}\) | Manufactured in standard joint lengths for ease of running. |

| End Connections | \(\text{API}\) \(\text{Thread}\) (e.g., \(\text{BTC}\), \(\text{LTC}\), \(\text{STC}\)) or Beveled | – | Customized to match the casing/liner running string. |

—

10. Installation and Operational Advantages: Longevity and Minimal Intervention

The decision to deploy a pipe based wire wrapped screen impacts not just the initial completion phase, but the entire operational lifespan of the well, reducing the frequency of costly interventions.

10.1. Running and Setting Reliability

The mechanical strength derived from the \(\text{API}\) base pipe ensures unparalleled reliability during installation:

- Resistance to Drag and Snagging: Unlike many mesh or pre-packed screens, the robust, all-welded construction of the wedge wire jacket can tolerate moderate rubbing and drag against the borehole wall or pre-drilled liner without damage or deformation to the slots. The high axial strength allows the screen string to be pushed or pulled safely through highly deviated or horizontal sections.

- Reduced Risk of Screen Failure: The integrity provided by the **Double Layer Wire Wrapped Screens** effectively eliminates the risk of component failure during crucial running procedures, a common cause of delays and expensive fishing operations. The screen acts and handles like the production casing itself.

10.2. Comparison to Alternative Screens

The pipe based wire wrapped screen outperforms conventional screens in critical areas:

| Feature | Pipe Based Wire Wrapped Screen | Pre-Packed Screens (Sandwich) | Conventional Slotted Liner |

|---|---|---|---|

| Structural Strength | Highest (\(\text{API}\) Casing Strength Maintained) | Moderate (relies on internal pipe/outer shroud) | High (but weakened by slots) |

| Filtration Accuracy | Highest (Precision All-Welded Slots) | Good (relies on media permeability) | Lowest (slots often cut by saw with wide tolerances) |

| Resistance to Plugging | Excellent (\(\text{Vee}\)-Slot Self-Cleaning) | Good (but requires precise slurry design) | Poor (Slots are rectangular, prone to bridging) |

| Deformation Reliability | Excellent (Slot size integrity maintained even if pipe yields) | Moderate (deformation risks damage to the resin-coated sand) | Moderate (slots widen upon deformation) |

10.3. Longevity and Maintenance Reduction

The selection of \(\text{SS } 316\text{L}\) ensures that the primary filtration medium resists corrosion for decades. This corrosion resistance, combined with the structural robustness and self-cleaning \(\text{vee}\)-slot design, results in a screen that rarely requires chemical treatment for scale or fines removal, and virtually never requires mechanical intervention due to structural failure. This maximized service life is the ultimate economic driver for choosing the pipe base screen.

—

11. Economic and Environmental Impact

The significant initial investment in high-quality stainless steel pipe base screens is rapidly recouped through reduced operational expenditure and enhanced resource recovery.

11.1. Total Cost of Ownership (TCO)

TCO analysis overwhelmingly favors the pipe base screen due to:

- Minimized Intervention Costs: The single largest cost savings come from eliminating or drastically reducing the need for well workovers, fishing, or chemical treatments associated with screen plugging or failure. A single workover can eclipse the cost of the entire screen string.

- Sustained Production: The superior hydraulic efficiency and sand control reliability ensure that the well maintains its maximum potential production rate for a longer period, resulting in higher net present value (\(\text{NPV}\)) from the reservoir.

- Avoidance of Abandonment: In highly unconsolidated reservoirs, screen failure can lead to severe casing erosion or sand-out, necessitating premature well abandonment. The structural integrity of the pipe base screen prevents this.

11.2. Environmental and Safety Benefits

The use of stainless steel pipe base screens contributes positively to safety and environmental responsibility:

- Reduced NPT (Non-Productive Time): Reliable downhole equipment reduces the frequency of drilling or completion delays, minimizing personnel exposure and associated risks.

- Sustainable Material: Stainless steel, being a highly durable alloy, provides maximum service life. Furthermore, at the end of the well’s life, the steel components are fully recyclable, contributing to a circular economy in material usage.

- Optimized Resource Recovery: By maintaining the wellbore’s integrity and flow efficiency, the screen maximizes the recovery factor of the hydrocarbon or water resource, ensuring efficient resource management.

—

12. Conclusion: The Foundation of Wellbore Assurance

The **Stainless Steel Pipe Base Wire Wrapped Well Screen**—manufactured from corrosion-resistant \(\text{SS } 304\) or \(\text{SS } 316\text{L}\) and built upon an \(\text{API}\) certified casing base pipe—represents the pinnacle of wellbore sand control technology. Its design is a structural marvel, maintaining \(\text{97\%}\) to \(\text{98\%}\) of the original casing strength while providing a meticulously accurate, non-plugging \(\text{vee}\)-slot filtration medium.

The combination of the highest achievable mechanical integrity (critical for deep, deviated wells) with superior filtration characteristics (critical for sustained, high-rate production) makes these **Double Layer Wire Wrapped Screens** the most reliable and economically sound solution for mitigating sand production. From the superior pitting resistance offered by \(\text{316L}\)’s molybdenum content to the fundamental assurance that its slots will not widen under formation pressure, every element of this screen is engineered for guaranteed, long-term wellbore success. Investing in this technology is not merely a component purchase; it is an investment in the long-term, high-rate, and reliable production of the well.