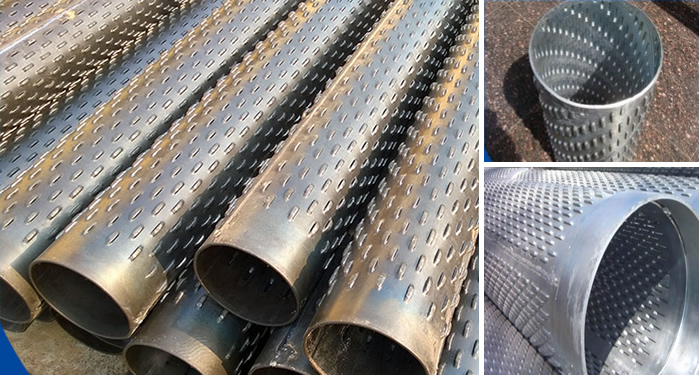

ASTM A 312 stainless steel 316L Perforated Casing screen Pipe

November 15, 2017

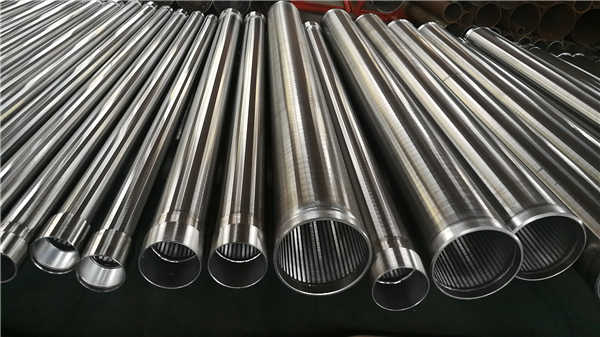

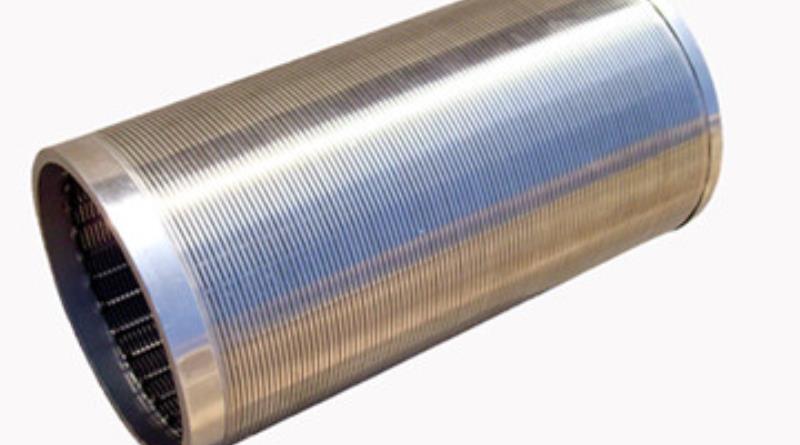

johnson continuous slot pipe based water well screens

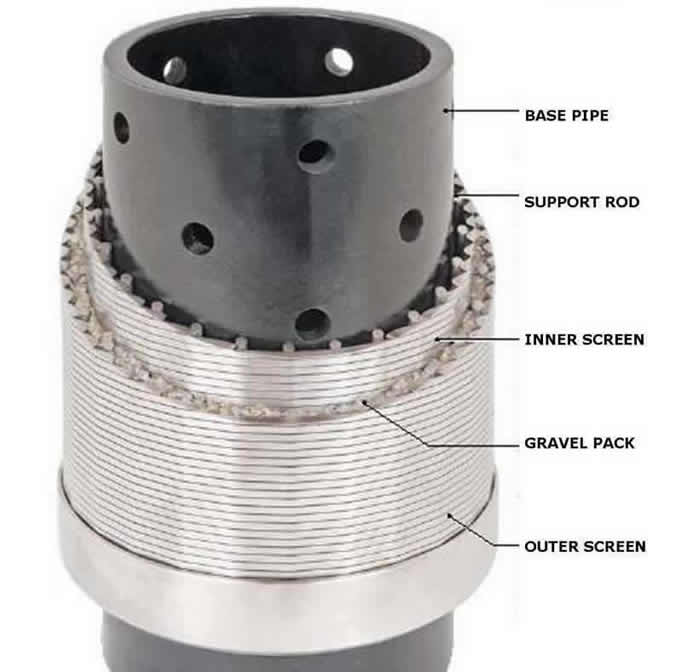

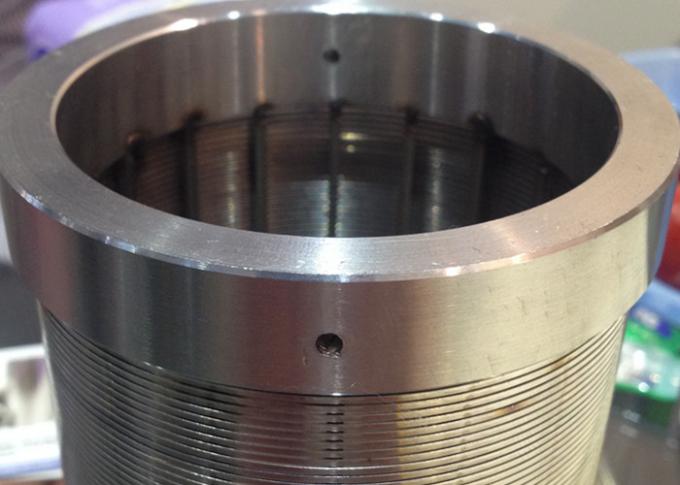

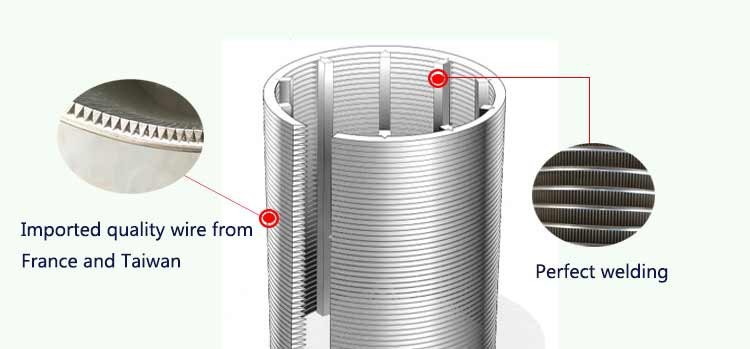

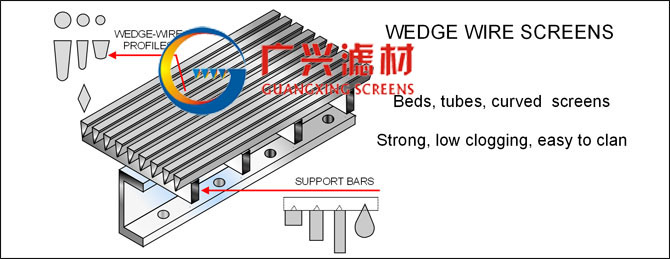

November 17, 2017stainless steel wedge wire screen is manufactured by a v or wedge shaped wire around an internal array of

longitudinal support rods. Each intersecting point of these wire is fusion welded.

The v or wedge shaped profile wire wraps around the support rods over the full length of the screen creating a continuous slot opening, hence the screen allows water (oil) to enter your well freely in ample quantities,

while at the same time keeps the majority of sand and gravel out of the well.

Technical Specification of wedge wire screen/johnson screens

| Specification (wedge wire): | Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

| Specification (support rod): | Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

| Note: other specifications available as per request | |

| Slot size | 0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

| Material: | galvanized low carton (LCG), stainless steel (304,316 etc.) |

| Length | up to 6 meters. |

| Diameter | from 25mm to 1200mm. |

| End connection | Plain beveled ends, flanged or threaded couplings |

Johnson screens strainer is manufactured by a v or wedge shaped wire around an internal array of longitudinal support rods.

Each intersecting point of these wire is fusion welded.The v or wedge shaped profile wire wraps around the support rods over the full length of the screen creating a continuous slot opening, hence the screen allows water (oil) to enter your well freely in ample quantities, while at the same time keeps the majority of sand and gravel out of the well.

Surface treatment:

The main properties of stainless steels, i.e. their corrosion resistance, is due to a ‘passive’,chromium rich complex, oxide film that forms naturally on the surface. However stainless steel cannot be considered corrosion resistant under all service conditions: depending on its composition and the surrounding environment, the passive layer can be broken down and prevented from reforming. The surface then becomes active, resulting in corrosion. It usually occurs in small areas deprived of oxygen such as around mechanical joints, tight corners or welding areas. The result can be localised forms of crevice or pitting attack.

THREADED CONNECTIONS

Male/female threaded joints can be supplied according to various standards

• BSP (gas) thread for the smallest diameters, up to 6”

• API threads such as STC (up to 13 3/8”) or bTC

• Connections according to the German Din 4922 standard can also be supplied.

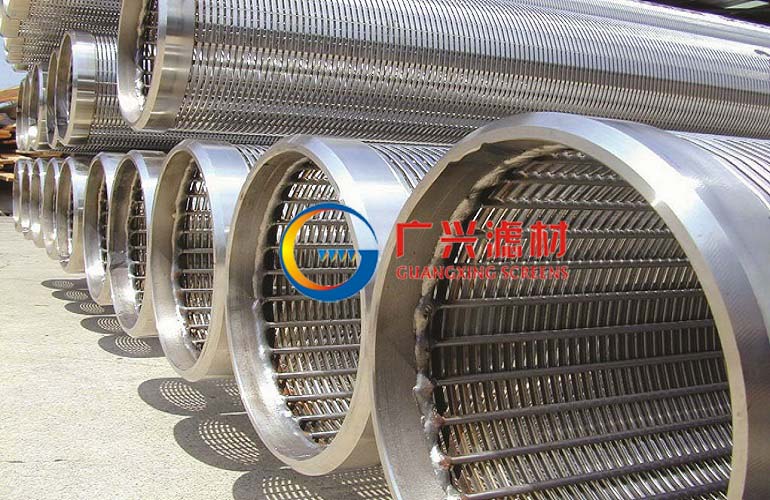

Features of stainless steel Johnson Screens, Vee-Wire continuous slot screen

Protection for your pump

The slots can be very narrow and precisely sized to keep out even fine sand grains which could otherwise destroy your pump through abrasion.

Lower pumping cost

Even with narrow slots, the total open area fort the water to enter is far higher than any other kind of screen design.

Longer wear life

The slots widen inward so sand grains don’t wedge and plug.

The screen can be stainless steel for maximum corrosion resistance.

The high open area of a Johnson screen lets the water enter slowly to avoid the problems which arise when water is pumped at high velocity.

(If water passes into the screen too quickly, pressure drops and gasses are released, allowing minerals to drop out of solution and form encrustation on the screen surface. High velocity water can also erode the screen, causing the slots to widen and allow sand to enter the well).

slot water well screens, continuous slot wedge wire screens/johnson screens

applications of stainless steel Johnson Screens, Vee-Wire continuous slot screen

Architecture & Construction

Food & Beverage Screens

Mineral & Aggregate Processing

OEM Screen Components

Pulp & Paper Screens

Refining & Petrochemical

Water Process & Fluid Treatment

Water Well

Screening and processing solutions are custom engineered to optimize performance. The company will work with you to build the best possible solution for your project. Known world-wide for their innovative stainless steel Vee-Wire® screens, Johnson Screens also provide top-of-the-line progressing cavity pumps, PVC screens and pipes, coagulant and flocculent water treatment systems, processing equipment and more.