single wedge wire filter nozzle, Filter Nozzle Screen For Water Treatment

June 14, 2018

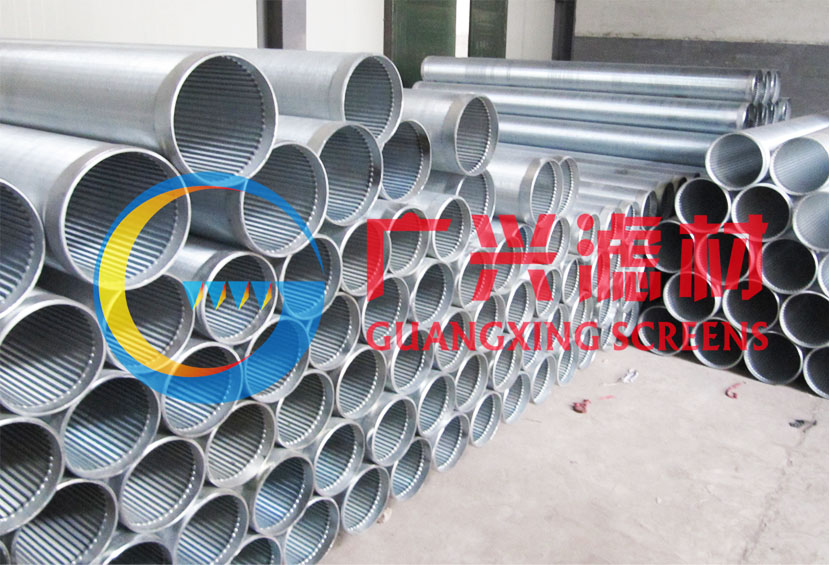

slip on wire-wrapped screens

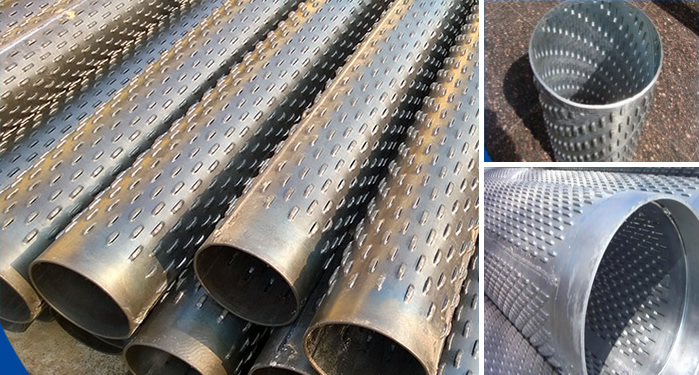

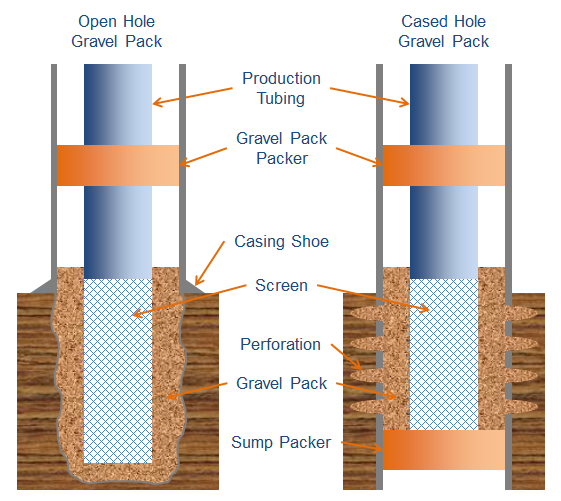

July 9, 2018Sand screens are of importance in producing oil, natural gas and water which are often located deep underground. Large drills are used to bore below the surface of the earth to collect oil or gas. Then sand screen is inserted into the bore allowing natural oil, gases to come in while prevent sand out except very fine particles. Sand screen is like a separator of gas, oil and sand. Once the large sand entering into the bore, it can decrease the production or even make the drilling equipment unworkable.

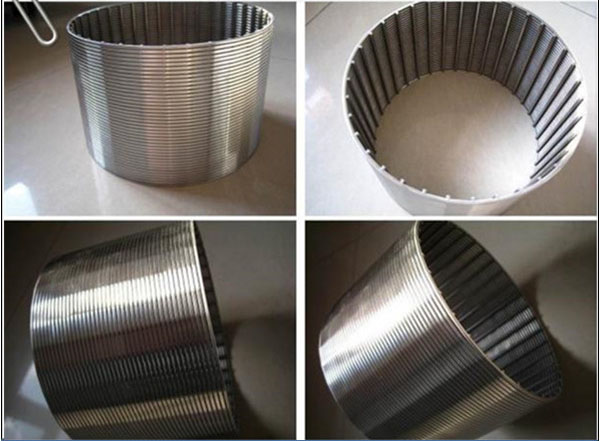

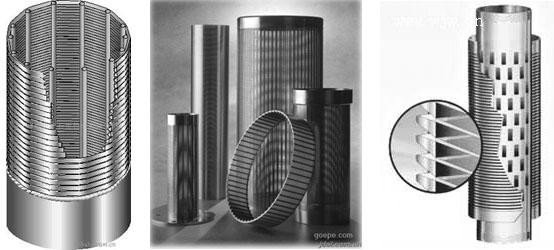

The oil well sand control screen consists of a base pipe that conforms to the API standard and a high-precision filter water pipe.

Screen size: 2.2*3.0mm, 2.3*3.0mm, 3.0*4.6mm, 3.0*5.0mm, etc.

Specifications of the ties: 3.8mm / 22, 3.8mm / 32, 3.8mm / 48, 3.8mm / 50

Features of Oil well sand control screen:

1. It has strong pressure bearing capacity. With the support of the inner layer base pipe, the external filter pipe will be deformed locally in time, the gap will not increase, and the sand control performance is more reliable. Suitable for harsh environments.

2. The outer screen has a uniform gap and the error is 0.05mm, which can effectively prevent sand.

3. Screen gap density Due to other screen tubes, the flow resistance is reduced, which greatly increases oil and gas production.

4. The pipe diameter is fine, which reduces the construction difficulty of drilling.

5. The continuous V-shaped structure reduces the infiltration velocity of the water flow and reduces the pressure on the pipe body and equipment.

6, the base pipe material is API standard J55, K55, N80, etc., the outer screen is stainless steel 304, can also use other materials according to customer requirements.

Applicable environment: deep wells in kilometers, oil wells, geothermal wells, and stratum with poor construction conditions.

Sand Control Screen