Johnson V Wire Water Well Screen,screen wire

November 29, 2017

Johnson Screens stainless steel well screens

December 6, 2017Johnson Screens’ continuous-slot, Vee-Wire construction of Johnson’s rod based screens

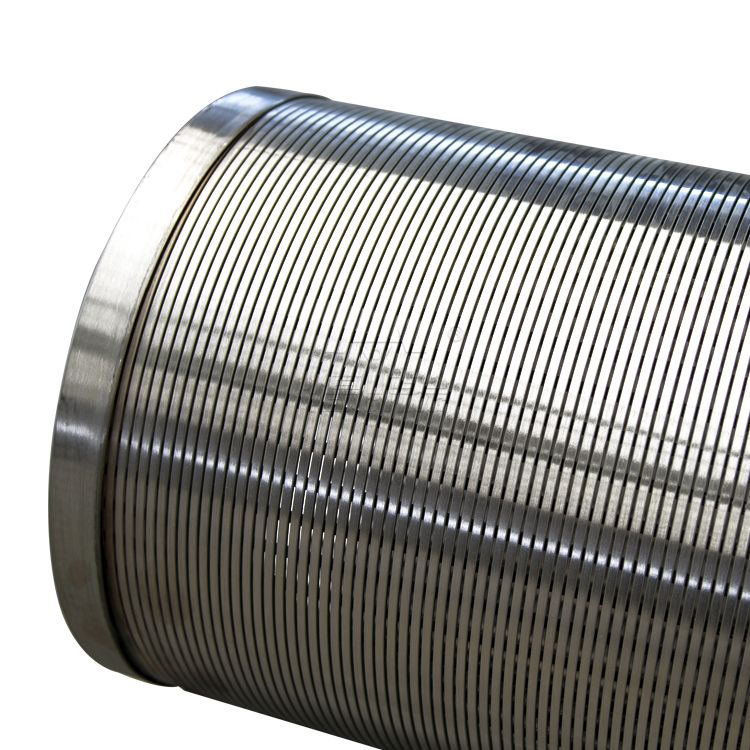

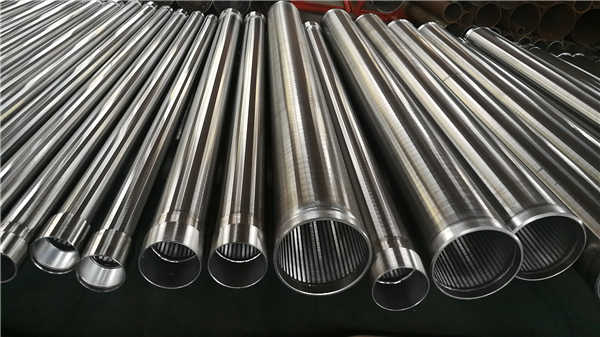

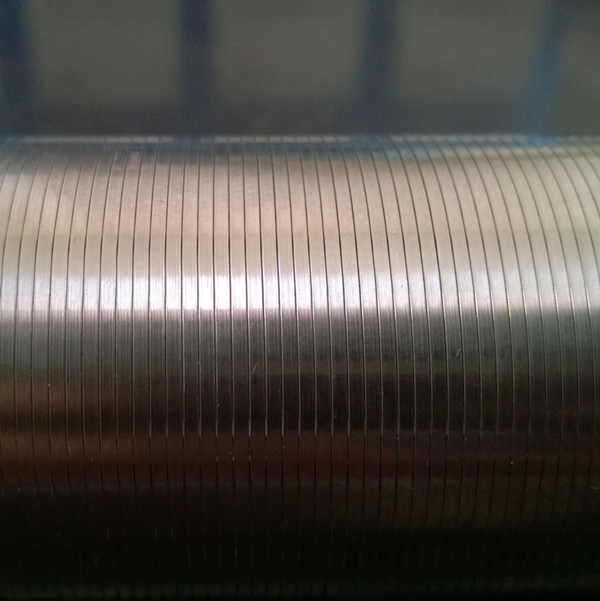

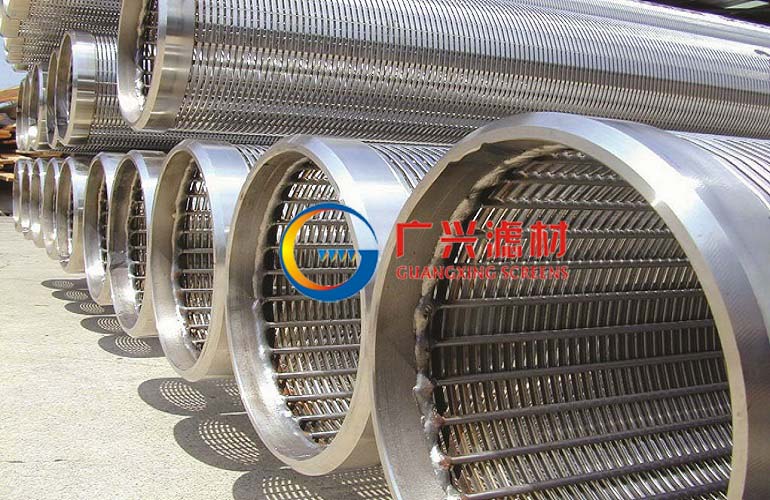

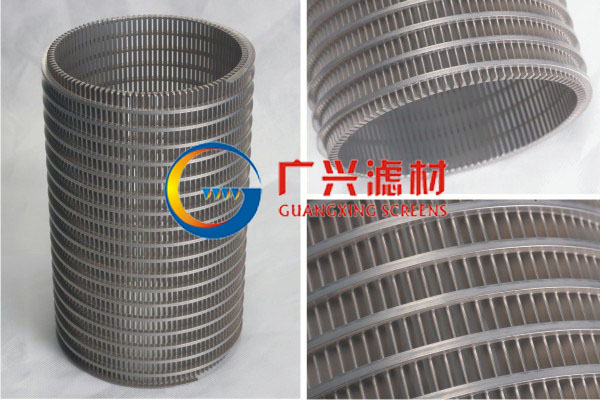

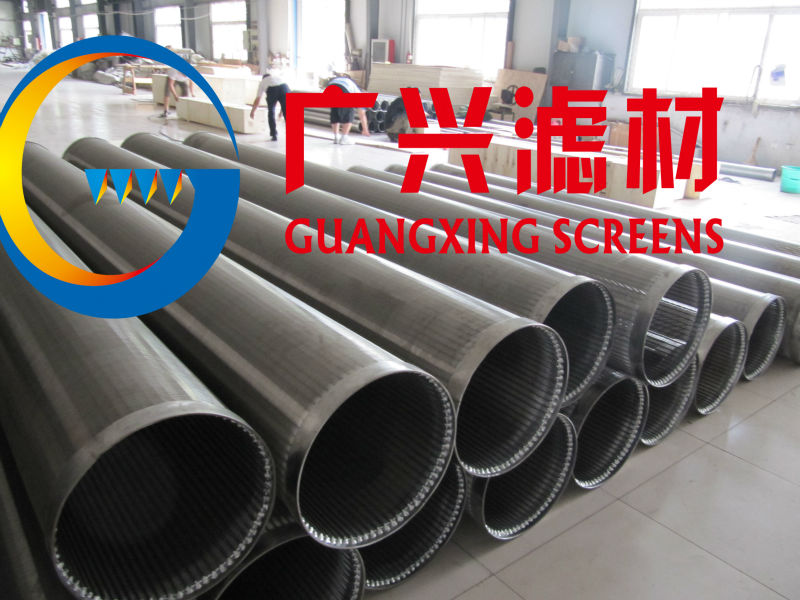

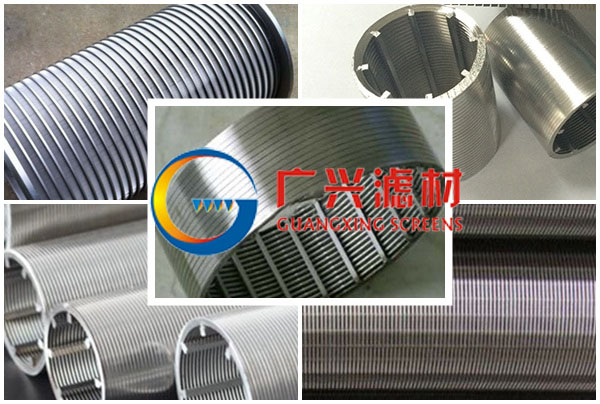

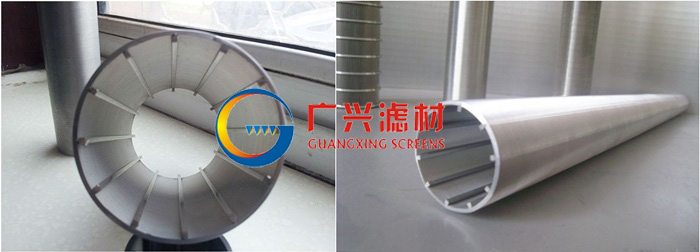

Johnson Screens’ continuous-slot, Vee-Wire construction of Johnson’s rod based screens is known around the world as the industry’s best well screen. Providing more open area, these non-plugging well screens have a tight slot tolerance, effective sand control and a lower entrance velocity. Our manufacturing capabilities covers the full range from shallow wells to deep wells, where the collapse resistance may be achieved with the use of heavy-duty Vee-Wire. Johnson Screens’ specific continuous-slot construction aims to optimise flow rates, minimizes clogging and help develop the water-bearing geological formations faster. It is best applied in the following situations: Geological formations comprised of small, fine particles Water wells where gravel packs will be installed Thin aquifers, where maximum open area is required Large- and small-diameter deep wells Available for both small- and large-diameter applications, Johnson rod based screens are available in stainless steel, low carbon steel and PVC with slot sizes as small as 0.1 mm (0.004 in.) and lengths up to 12 m (40 ft.).

StandardStandard

JB/T 8734—2012

Others like BS, DIN, AS/NZS, ICEA upon request

Application

The product is suitable for flexible connections of electric appliances, instruments, electronic devices, automatic devices, and other places requiring screen.

Characteristic

1. Rated voltage

300V/300V

2. Maximum conductor temperature at normal operation

70°C

3. Minimum ambient laying temperature

0°C4. The product has the good property of electromagnetic compatibility.

| Material | SS304, SS304L, SS316, SS316L, SS321, Duplex, Hastelloy, etc | ||||||

| OD Range | 19mm-2000mm | ||||||

| ID Range | 13mm-1981mm | ||||||

| Length Range | Up to 6000 mm | ||||||

| Slot Range | 20 micron to 3000 micron (Tolerance:+-5 micron) | ||||||

| Wedge Wire | 0.5×1.5 | 0.75×1.5 | 1×2 | 1.5*2 | 2×3 | 2*4 | 3*5 |

| Support Rod | 1.5×2.5

2×3 |

1.5×2.5

2×3 |

1.5×2.5

2×3 |

1.8*2.5

2×3 |

2×3

2×4 3×5 3×6 3×10 4×7 |

2×4

3×5 3×6 3×10 4×7 5×6 |

3×5

3×6 3×10 4×7 5×6 5×8 |

| End Finishing | Thread fitting, Flange, Closed Plated, Resistance welded closed plate, Metal Ring, etc | ||||||

| Note | Customized According To Requirement | ||||||

stainless steel screen is strong and versatile enough to be installed into window and door frames in order to resist vandals and keep out insects. Government agencies and construction companies rely on stainless steel screen to provide protection to the interior of buildings from broken glass and debris caused by inclement weather. Panic room manufacturers install stainless steel screen and stainless wire mesh inside walls and doors to provide enhanced security from intruders. Stainless steel screen also works well to guard roof gutters from tree leaves and other debris.

Optimum structural strength for heavy loads

Minimal plugging and blinding

High pressure/pulsating pressure capability

Corrosive application suitability

Thermal resistance

Long-life — almost endless cleanability

Sterile application / food industry suitability

Low pressure drop

High flow rate

Application:

widly used in coal,mine,water treatment and etc field.