Wedge Wire Sieve Plate,Sieve Plate Wedge Wire Lauter Tun Screen

February 24, 2018

304 stainless steel well screen filter

March 4, 2018Sand-control technology with wire wrapped liner pipe Packing-sand control knowledge

Today to bring you around the wire wrapped liner pipe gravel filling sand control technology, I hope we have harvested. Sand-control technology of wire-liner gravel Packing This is the world’s most common sand control technology, about 90% of all the total sand control construction, the status of the important. We will focus on this. It has high sand-control strength, high success rate, long validity, good adaptability, after decades of research, application and development, technology is very mature.

In vertical wells, directional wells (even horizontal wells), offshore wells, conventional wells, steam injection thermal recovery wells, new and old wells are widely used, the effect is very good, is the most preferred sand control methods. This method is referred to as “gravel filling”.

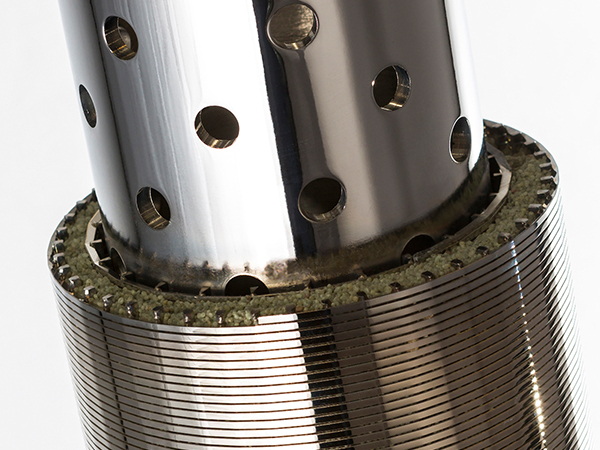

In fact, it is made from the combination of a wire liner and a packed gravel to complete the sand control.

(i) Technical principles and process characteristics The method of sand control can be used in the hole (open hole or casing) is under the sand formation into the metal fully welded winding wire wrapped liner pipe , then pump gravel mortar in the wire wrapped liner pipe and hole annulus, if the casing perforation completes the well, but also the part of the gravel squeeze incident hole and the surrounding formation cavity, using the bridge plugging effect of gravel to prevent the formation of sand migration, The filled gravel is also blocked by the wire wrapped liner pipe.

This multistage filtration barrier ensures that the oil flow along the filling body porous system is continuously raised to the ground through the screen liner, while the formation sand is well made in the ground, and the production of the well is not out of sand or slightly out of the sand.

This shows that gravel-filled sand control has the following characteristics:

1. High Sand Control strength The dense gravel backfill in the casing prevents the

for mation structure from being destroyed, while the metal filament screen itself has great strength and large seepage area, so the flow resistance through the sieve seam is very small. Therefore, the filtration system can prevent the formation of sand with the large production pressure difference.

The maximum pressure difference of gravel filling with 2.45MPa was studied by experiment.

2. Length of validity

Because of its high sand-control strength, stainless steel wire wrapped liner pipe is corrosion resistant, the chemical properties of gravel (quartz sand) are stable, and the filtration system of wire wrapped liner pipe and filling body has no moving parts, the sand grains are blocked from the system, so the filtration system can guarantee the long-term safe production, can work effectively for 8-10 years, and almost finish a permanent sand-control filtration system.

3. Wide range of adaptation Because the sand control mechanism is based on multistage filtration, plus many years ‘ development, the technology is mature, the choice of technology is many, so it is very adaptable to stratum and well. Regardless of the length of the Well section, the formation fluid characteristics, whether straight wells, inclined shafts, conventional wells, thermal recovery wells, single-layer completion or multi-layer completion can obtain over work, the success rate of more than 90%.

But silty sand rock is not suitable, because the extremely fine formation sand can gradually invade the filling body reunion blockage and prevent sand failure.

4. Relatively small loss of capacity Any kind of sand control method inevitably brings the production capacity loss of the well, and it is also the price that must pay for the sand control to ensure the normal production of the well. field data show that the normal pipe gravel filling capacity loss of about 30%, but the effective remedial measures, the capacity loss can be reduced to 10%, which is completely acceptable.

These technical measures are specifically discussed in later chapters.

(b) Gravel packing scope of application and well-chosen conditions

1. Not suitable for fine sand rock (d50<0.07mm);

2. The casing diameter is less than 5in small hole construction difficulty, does not apply or does not use;

3. For multilayer reservoir, if the oil field development plan requires frequent replacement of the oil wells which are mined in the strata; 4. Water injection wells are not applicable and horizontal wells are being popularized.

In addition to the above conditions, the vast majority of oil and gas wells and strata are suitable for the use of gravel-filled sand control technology, and has achieved good results, showing a strong vitality.