Stainless Steel Pipe Base Screens Comprehensive Guide

October 10, 2025

: Analyzing the Impact of Well Screen Diameter on Horizontal Gas Well Productivity

December 5, 2025The Geo-Resilient Vee-Wire Filter System: Designing an Anti-Clogging Well Screen for High-Enthalpy Geothermal Extraction

The pursuit of sustainable, baseload power from geothermal reservoirs—particularly those characterized by high temperatures and corrosive fluid chemistry—presents one of the most demanding engineering challenges in subsurface resource extraction. Unlike the relatively benign environments of conventional oil and gas or low-temperature water wells, geothermal brines are aggressive cocktails of high heat, pressure, chlorides, non-condensable gases ($\text{CO}_2$ and $\text{H}_2\text{S}$), and dissolved silica. The failure point in these systems is frequently the well screen, the critical interface between the hot reservoir rock and the cold steel wellbore, where rapid pressure and temperature drops trigger a catastrophic process known as scaling or mineral precipitation. Scaling—primarily driven by silica ($\text{SiO}_2$) and calcite ($\text{CaCO}_3$)—can rapidly plug the screen slots, severely restricting fluid flow (inflow impedance), decreasing well output, and necessitating extremely costly workover interventions.

To overcome this fundamental limitation, the design of an anti-clogging geothermal well screen must evolve beyond simple particle exclusion. It requires a holistic design philosophy rooted in thermo-chemical resistance, precision fluid dynamics, and advanced metallurgy. The resulting product, which we define as the Geo-Resilient Vee-Wire Filter System, must integrate a specialized geometry that inherently resists particle bridging with a high-performance alloy chosen for its imperviousness to high-chloride, sour service corrosion. This system is a high-cost, high-reliability component whose initial investment is justified by the immense operational savings realized from the avoidance of premature scaling and subsequent loss of production. The following exposition details the rationale, specifications, and features of this critical piece of subsurface engineering, a product whose entire existence is a defense against chemical and physical entropy.

1. The Hostile Frontier: Geothermal Environments and the Clogging Imperative

Geothermal well environments, especially those tapping into high-enthalpy fields (temperatures exceeding $200^{\circ}\text{C}$), represent an exceptionally corrosive and mineral-rich fluid environment that places extreme demands on downhole equipment. The well screen’s failure mechanisms are complex and interconnected, requiring a multi-faceted design response.

The primary environmental adversaries of the well screen can be categorized into three interconnected threats: Corrosion, Scaling (Chemical Precipitation), and Particle Bridging.

-

Corrosion: High-temperature brines often contain elevated concentrations of chloride ions ($\text{Cl}^-$), hydrogen sulfide ($\text{H}_2\text{S}$), and carbon dioxide ($\text{CO}_2$). The combination of high temperature and high chloride concentration drastically lowers the threshold for pitting corrosion and stress corrosion cracking (SCC) in conventional steels. Sour service conditions (high $\text{H}_2\text{S}$) further demand materials resistant to sulfide stress cracking, a vulnerability intensified by the tensile stress inherent in a welded screen structure. The screen metallurgy must be non-negotiable in its resistance to this cocktail.

-

Scaling (Chemical Precipitation): This is the most destructive phenomenon. As the superheated reservoir fluid travels up the wellbore, it experiences a drop in both pressure and temperature.

-

Silica Scaling: As the fluid cools, dissolved silica ($\text{H}_4\text{SiO}_4$) transitions from a stable dissolved state to an oversaturated state and begins to polymerize and precipitate as hard $\text{SiO}_2$ or silicates, often clinging tenaciously to the screen wire surfaces and restricting the slot opening.

- Calcite Scaling: The pressure drop can cause the flashing of the liquid water to steam, stripping dissolved $\text{CO}_2$ from the brine. The removal of $\text{CO}_2$ increases the $\text{pH}$ of the remaining liquid phase, reducing the solubility of calcium carbonate ($\text{CaCO}_3$), which then precipitates as calcite scale, often quickly filling the slots from the inside out.The screen design must minimize the pressure drop ($\Delta P$) across the screen face to inhibit flashing and precipitation right at the fluid entry point.

-

-

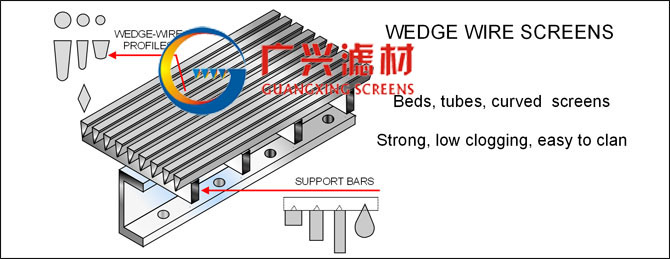

Particle Bridging: Fine sand and silt from the formation migrate toward the wellbore. While the screen is designed to exclude the bulk of the formation, these fines can lodge within the screen slots, particularly if the slots are rectangular (as in slotted liner pipe). Once a few particles bridge the gap, they create a site for further fine particle accumulation and, critically, a nucleation site for mineral scale deposition, accelerating the clogging process.

The engineering solution must therefore be a specialized well screen that employs a high Pitting Resistance Equivalent Number (PREN) alloy to defeat corrosion, combined with a precise geometry that defeats both particle bridging and chemical nucleation.

2. The Geometry of Anti-Clogging: Advanced Vee-Wire Design

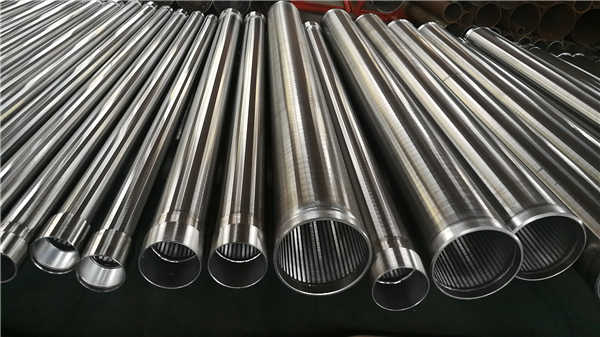

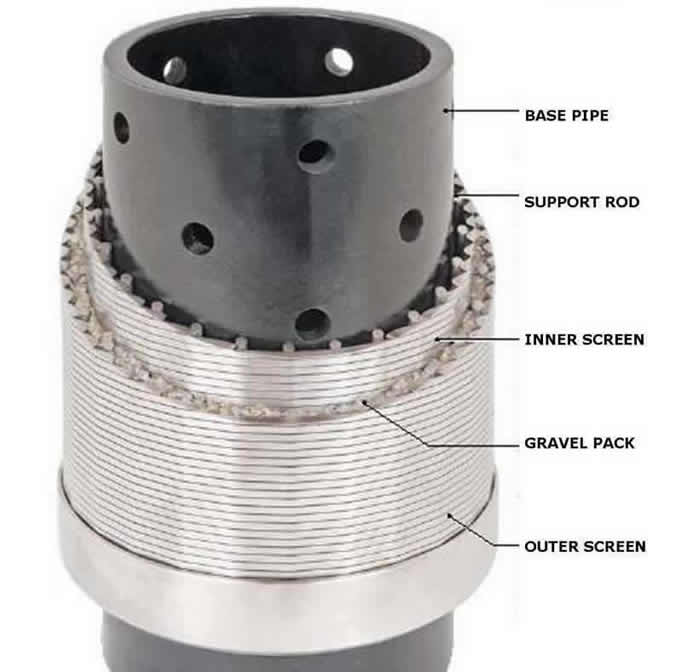

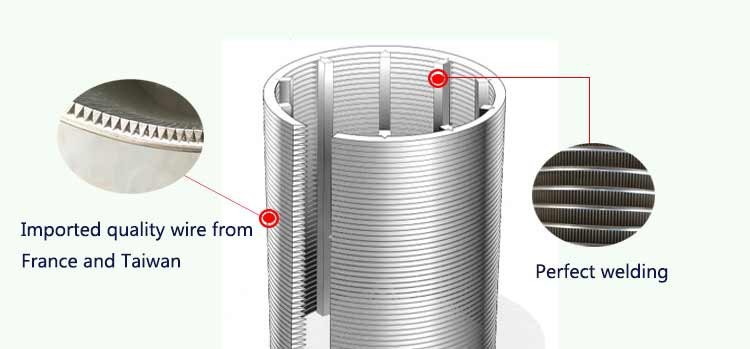

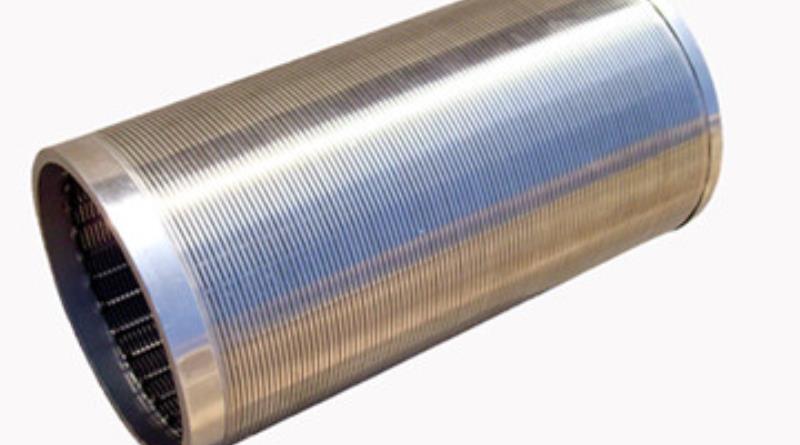

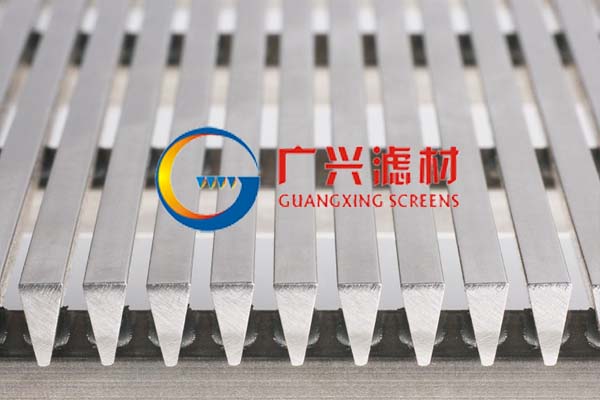

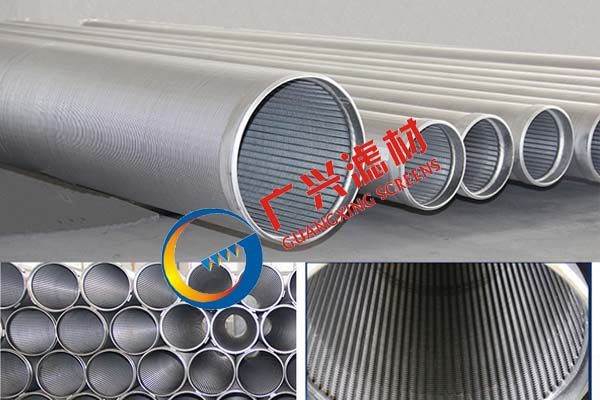

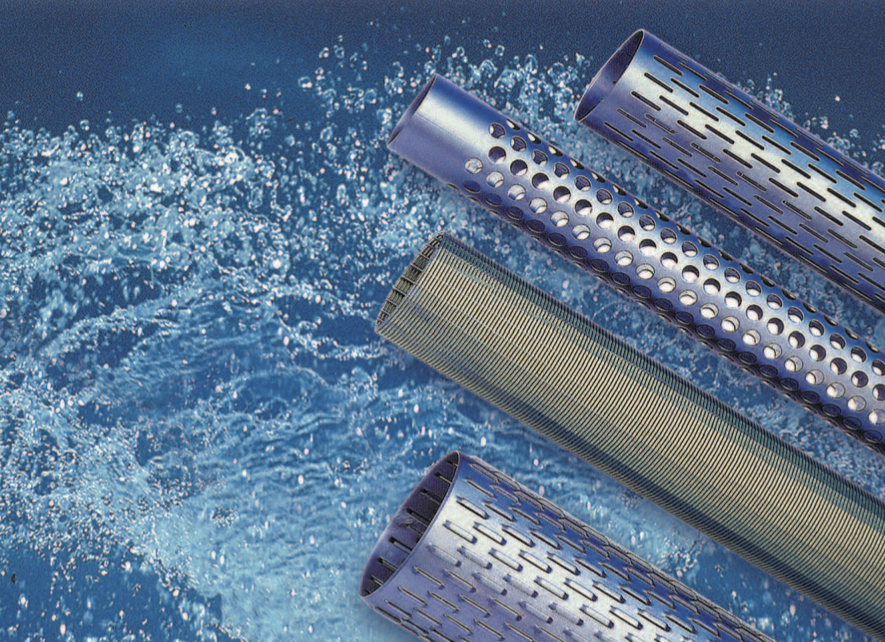

The Geo-Resilient Well Screen must utilize a Vee-Wire (or Wedge-Wire) design, as its geometric principles are fundamentally superior to slotted liners or perforated pipe for non-clogging performance. The screen is constructed by helically wrapping a continuous V-shaped wire around an array of longitudinal support rods, with each intersection point precision-welded.

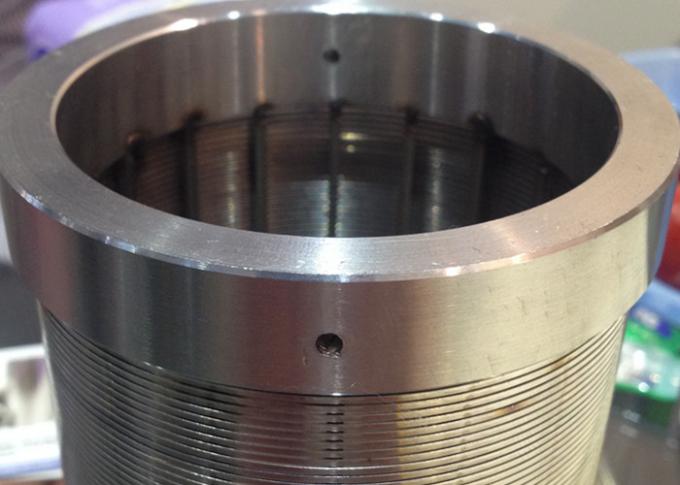

The Non-Plugging V-Shape Aperture

The defining feature is the V-shaped aperture formed by the wire profile. The slot opening (width) is maintained on the outer diameter (OD) surface, and the slot aperture widens slightly towards the inner diameter (ID). This feature is critical for anti-clogging:

-

Particle Rejection: Any particle that manages to pass through the narrowest point of the slot opening must be able to continue its journey into the wellbore. The outward-tapering V-shape ensures that if a particle passes the external slot, it cannot be physically wedged or bridged further down the slot, which is the mechanism that plugs rectangular slots. The Vee-Wire design forces the formation of a natural, stable filter cake outside the screen, rather than clogging within it.

-

Maximized Open Area: The continuous slot design, running the entire length of the screen, provides the maximum possible open area per unit length—often 3 to 10 times higher than conventional slotted liners. This high open area translates directly into a minimal fluid entry velocity and, crucially, a minimal pressure drop ($\Delta P$) across the screen face. As discussed, minimizing $\Delta P$ is essential to inhibit the flashing and subsequent precipitation of calcite and silica scale directly onto the wire surface.

The Anti-Clogging Enhancement: Surface Finish and Flow Optimization

For geothermal service, the standard Vee-Wire design must be enhanced to maximize resistance to chemical precipitation:

-

Precision Slot Taper: The internal slot taper is optimized to guarantee hydraulic continuity and to prevent any micro-recirculation zones within the slot itself, which could otherwise act as nucleation sites for scale crystallization.

-

Electro-Polishing or Passivation: The entire assembled screen, made from high-alloy material, must undergo a specialized finishing process, such as electro-polishing or chemical passivation. This process removes micro-imperfections, burrs, and surface contaminants (like free iron) left by fabrication. The resulting ultra-smooth surface finish and the development of a passive chromic oxide layer ($\text{Cr}_2\text{O}_3$) significantly reduce the surface energy and chemical affinity of the screen material, making it mechanically more difficult for mineral crystals (silica, calcite) to nucleate and adhere to the wire surface.

The final Geo-Resilient screen is thus a geometrically precise filter that is hydraulically designed to prevent the physical wedging of formation particles and chemically conditioned to minimize the adherence of mineral scale. The slot width selection will be highly specific to the formation’s particle size distribution ($D_{50}$), typically designed to exclude $40\%$ to $70\%$ of the formation or to retain a meticulously placed gravel pack material.

3. The Metallurgical Defense: Choosing High-Nickel Alloys

The aggressive chemical nature of geothermal fluids means that material selection is the single most important factor determining the screen’s service life. Standard low-carbon steel (like A36 or API 5L) is immediately ruled out due to its susceptibility to rapid pitting and sulfide stress cracking. The material must be a high-performance alloy selected based on its Pitting Resistance Equivalent Number (PREN), which quantifies an alloy’s resistance to localized pitting corrosion in chloride-rich environments:

Super Duplex Stainless Steel (The Baseline for Corrosivity)

For most high-temperature, high-chloride geothermal fields, the baseline material requirement is Super Duplex Stainless Steel (SDSS), typically conforming to UNS S32750 or S32760.

-

Rationale: SDSS possesses a balanced microstructure of approximately $50\%$ austenite and $50\%$ ferrite, providing a unique combination of high mechanical strength (exceeding many conventional stainless steels) and excellent corrosion resistance.

-

PREN Value: SDSS typically achieves a PREN $\geq 40$. The high content of Chromium ($\sim 25\%$), Molybdenum ($\sim 3.5\%$), and Nitrogen ($\sim 0.25\%$) guarantees exceptional resistance to chloride-induced pitting and crevice corrosion, which are the primary modes of failure for screens in geothermal brines. Its high yield strength is also necessary to withstand the external collapse pressure in deep wells and the structural loads during installation.

Higher Nickel Alloys (For Extreme Service)

In fields characterized by ultra-sour conditions (high $\text{H}_2\text{S}$ and $\text{CO}_2$) or temperatures consistently exceeding $250^{\circ}\text{C}$, even SDSS may not suffice due to susceptibility to environmental cracking. In these extreme cases, higher Nickel Alloys are mandated, such as Inconel 825 or Hastelloy C276.

-

Inconel 825 (UNS N08825): A Nickel-Iron-Chromium alloy with added Molybdenum and Copper. It offers superior resistance to general corrosion, pitting, and stress corrosion cracking in reducing and oxidizing acids, making it highly effective against the complex chemistries encountered in geothermal brines.

-

Hastelloy C276 (UNS N10276): A Nickel-Molybdenum-Chromium superalloy with Tungsten. It offers the highest level of resistance to localized corrosion, making it the material of choice when $\text{Cl}^-$ concentration and temperature are at the extreme upper limits and absolutely no failure is tolerable.

The engineering decision is always a life-cycle cost analysis: the high initial cost of the Super Duplex or Inconel screen is justified by extending the screen’s operational life from perhaps 5 years (for low-grade steel) to 20+ years, avoiding multiple $5 \text{ million USD}$ workover operations.

| Parameter | Specification / Requirement | Super Duplex (UNS S32750) | Higher Nickel Alloy (Inconel 825) |

| Material Standard | ASTM A790/A928 (Pipe) or B407 (Tubing) | ASTM A240/A790/A928 | ASTM B423 / B407 |

| Application | High-Enthalpy Geothermal Wells | High $\text{Cl}^-$, $\text{H}_2\text{S}$ (Sour Service), $\text{T} \leq 250^{\circ}\text{C}$ | Ultra-Sour Service, $\text{T} > 250^{\circ}\text{C}$, Highly Acidic Brine |

| PREN Value | Mandatory $\text{PREN} \geq 40$ | Typically $\text{PREN} \geq 41$ | Typically $\text{PREN} \geq 32$ (Excellent SCC resistance due to high Ni) |

| Heat Treatment | Solution Annealing ($1080^{\circ}\text{C}$ and rapid cooling) | Mandatory after welding to avoid sigma phase formation | Annealed (Required for microstructure stability) |

| Chemical Composition | $\text{Cr} \sim 25\%$, $\text{Ni} \sim 7\%$, $\text{Mo} \sim 3.5\%$, $\text{N} \sim 0.25\%$ | $\text{Ni} \sim 42\%$, $\text{Cr} \sim 21.5\%$, $\text{Mo} \sim 3\%$, $\text{Cu} \sim 2\%$ | |

| Tensile Requirements | $R_{eH} \geq 550 \text{ MPa}$, $R_m \geq 750 \text{ MPa}$ | $R_{eH} \geq 220 \text{ MPa}$, $R_m \geq 586 \text{ MPa}$ |

4. Fabrication, Dimensional Control, and Operational Features

The Geo-Resilient Vee-Wire Filter is not just a collection of materials; it is a precision-fabricated pressure-retaining component. The severe demands of the geothermal environment necessitate fabrication and dimensional tolerances far stricter than those for general sand screens.

Fabrication Challenges and Control

The difficulty in manufacturing the screen arises from the need to precision-weld the high-alloy wire to the high-alloy rod. High-nickel alloys are sensitive to heat input, which can lead to the formation of detrimental intermetallic phases (like the brittle sigma phase in SDSS) if not precisely controlled.

-

Welding: Automated Resistance Welding or Laser Welding is mandatory to achieve the high energy density and low heat input necessary to weld the wire intersections without damaging the local microstructure of the SDSS or Inconel material. Post-weld heat treatment, typically solution annealing and rapid quenching, is mandatory for Super Duplex to re-establish the ideal $50/50$ austenitic-ferritic balance and restore maximum corrosion resistance.

-

Structural Strength: The screen is required to meet the collapse, burst, and tensile standards specified by API 5CT or API 11D1 (Packer and Sand Screen). The internal structure (support rods) must be robustly connected to the external Vee-Wire jacket and the end connectors to prevent structural failure under the high external pressure loads of deep wells.

Dimensional Specifications and Tolerances

The most critical dimensional specification is the Slot Width and its Tolerance.

-

Slot Width Tolerance: The slot width must be manufactured to extremely tight tolerances, typically $\pm 0.05 \text{ mm}$ ($\pm 0.002 \text{ inches}$) or tighter. This precision is non-negotiable, as the final sand exclusion and flow area are directly dependent on it. Inconsistencies lead to localized fluid acceleration, which exacerbates both erosion and scaling.

-

Ovality and Straightness: The screen must maintain excellent straightness and low ovality, particularly when designed to be run inside a casing or designed for swellable packer deployment. Non-straight screens increase frictional drag during running and complicate the setting of downhole tools.

| Parameter | Standard / Governing Code | Tolerance of Slot Width | Tolerance of Outer Diameter (OD) |

| Overall Standard | API 11D1 / ISO 17824 (Sand Screen Performance) | $\pm 0.05 \text{ mm}$ (critical for sand control and flow) | $\pm 0.25 \text{ mm}$ (critical for running clearance) |

| Substrate Pipe | ASME B36.10M / ASTM A790 (Super Duplex) | N/A | $\pm 0.5\%$ of nominal OD |

| Wall Thickness Schedule | Based on Collapse/Burst Calculation (API 5CT) | Thickness of Wire and Rods (Specific to manufacturer’s design) | $\pm 10\%$ of Substrate Pipe WT |

| Connection Type | API 5B / Proprietary Threading | N/A | N/A |

A Triumph of Geothermal Engineering

The Geo-Resilient Vee-Wire Filter System, designed specifically for the aggressive, scaling environment of high-enthalpy geothermal wells, represents a triumph of applied metallurgical and hydraulic engineering. It moves beyond the limitations of conventional sand screens by addressing the primary failure modes—corrosion and chemical scaling—head-on.

The use of high-PREN alloys like Super Duplex Stainless Steel or Inconel 825 provides the chemical barrier necessary to withstand the high-temperature, sour chloride brines. Critically, the adoption of the precision-fabricated Vee-Wire geometry, with its non-plugging V-shaped aperture and maximized open area, minimizes the flow velocity and pressure drop across the screen, effectively inhibiting the kinetic triggers for silica and calcite precipitation. This is further enhanced by specialized surface finishing to discourage crystal nucleation.

The high cost of the initial materials and specialized welding processes is a necessary investment. In the challenging economics of deep geothermal extraction, where workover costs are exceptionally high, the reliability and extended operational life delivered by the Geo-Resilient screen system are not merely features—they are fundamental prerequisites for the long-term viability and profitability of the geothermal power project. This engineered component is the essential interface that allows the thermal power of the Earth to be harnessed efficiently and sustainably.