Tilted wire welded wedge wire sieve bend screen for industry filtration

October 13, 2017

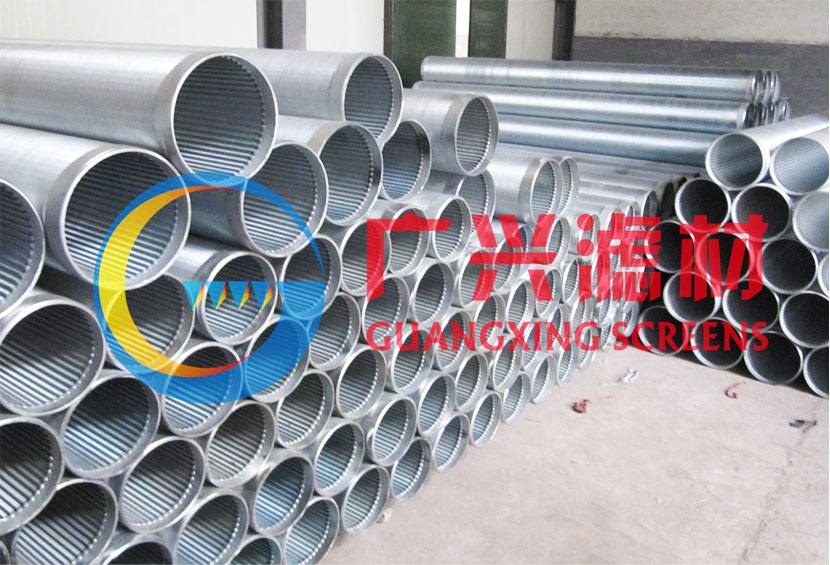

Water Well screen Perforated Casing pipe for drilling wells

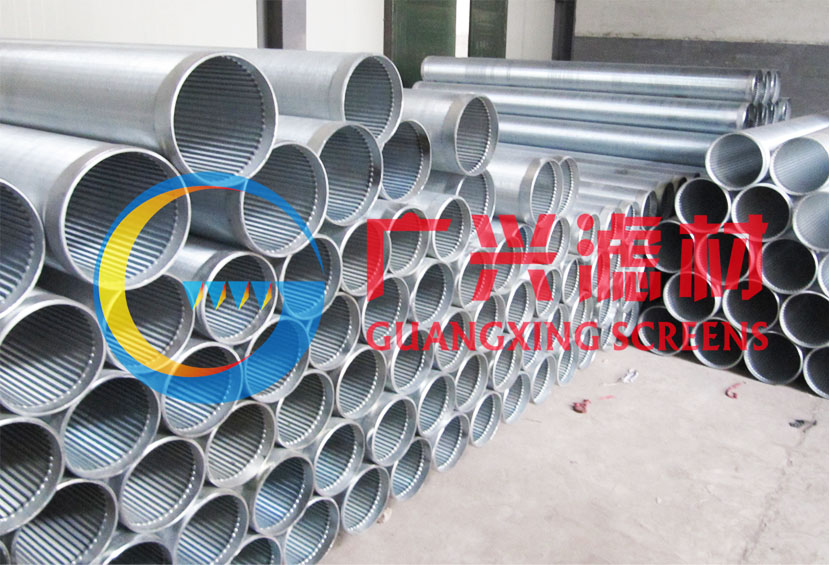

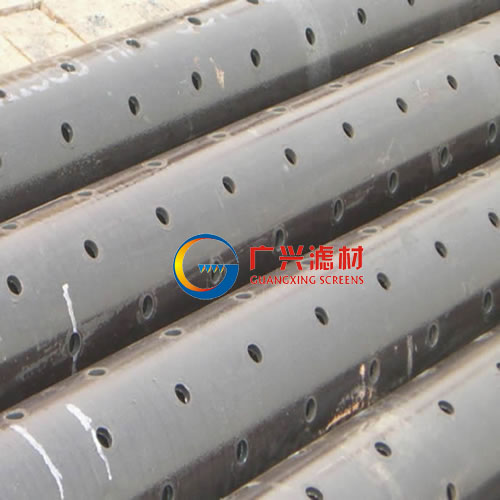

November 8, 2017A well screen is a filtering device that serves as the intake portion of wells constructed in unconsolidated or semi-consolidated aquifers. The screen permits water to enter the well from the saturated aquifer, prevents sediment from entering the well, and serves structurally to support the aquifer material.A well screen is an engineered device used in many water wells to help maintain a good water supply from the aquifer and allow for long-term satisfactory operation of the well.

The screen prevents rock fragments from entering the well, helps support the wall of the well and allows water to enter. Silt or sand particles may cause excessive abrasion and early failure of the well pump and/ or plugging of equipment in the home. In addition, sand may accumulate in a well and block off water-bearing zones.

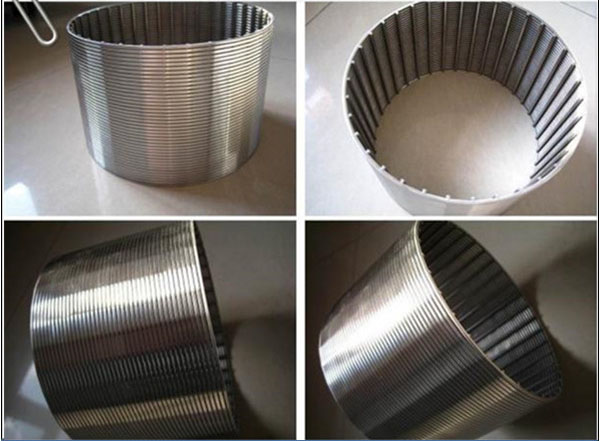

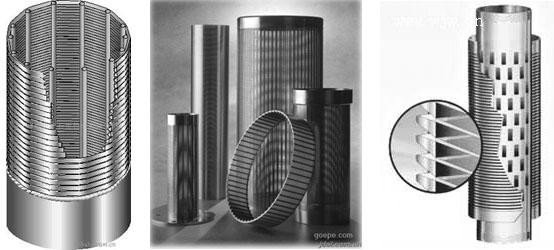

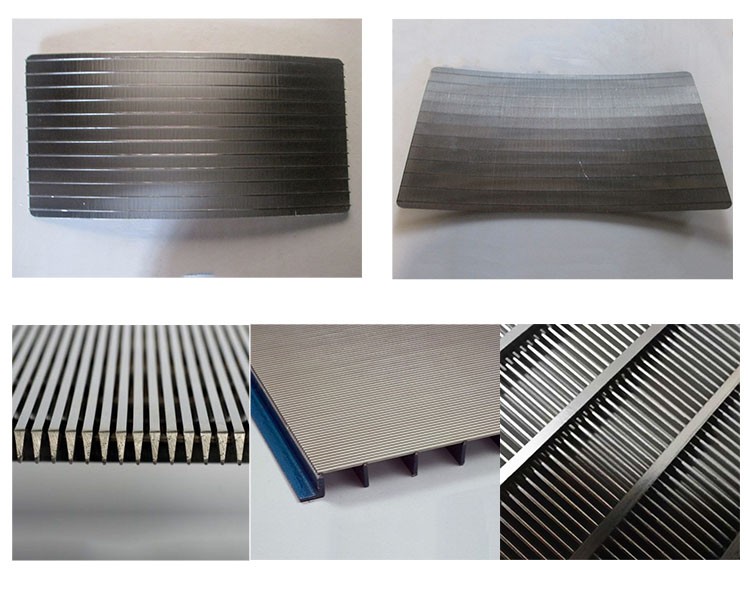

In all wells, it is preferable to have water enter slowly. Turbulent flow can more easily transport particles and agitated water may release minerals and clog up the well. Selection of the right screen and the right length of screen can help improve a well’s efficiency and productive life. A commonly used and effective screen type for water wells uses a continuous slot construction, made by wrapping and welding a continuous length of wire or plastic around vertical rods. Wrapped screens have an elongated triangle shape when viewed in cross-section with the “point” of the triangle oriented inwards so that the outside slot width is small compared to the inside spacing. This design allows particles that do penetrate the screen to continue through without getting stuck.

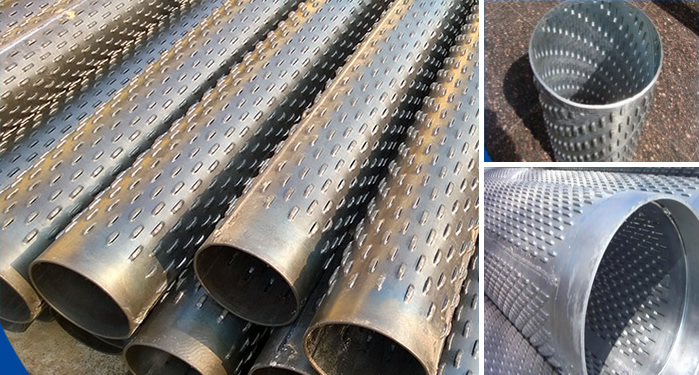

Screens are also made by precision machine slotting (vertical or horizontal slots) or by making louver openings. Louver type well screens (shutter screens) are typically used only for high yield wells. Screens are made in many different slot or opening sizes and are usually installed by fixing the screen to the end of the casing, which is then lowered down the well to the selected water-producing zone(s) of the aquifer.