Perforated Pipe for Wedge Wire,Wedge Wire Water Screen Pipe

May 30, 2018

single wedge wire filter nozzle, Filter Nozzle Screen For Water Treatment

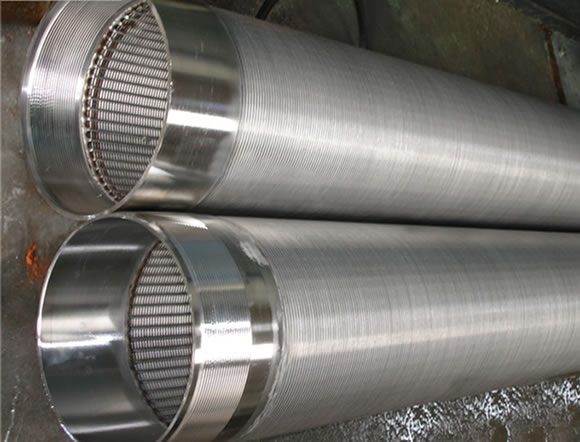

June 14, 2018Wedge screens are manufactured by resistance welding vee-shaped wire on support rods. The distance between the vee-shaped wire is controlled accurately, as it forms the slot

through which the filtrate flows. Welding is performed in a continuous rolled motion to join the wire and the rods. The welding process welds the continuous length of the wire to the

rods as it circulates.

welded wedge wire candle filters are ideal for removing particles of very small size upto 10 microns. These filters can be easily washed through a back flush of the steam.

Specifications of Welded Wedge Wire Candle Filter

1. The materials of Welded wedge wire candle filter: carbon steel, stainless steel

2. slot size: 0.15mm-3.5mm

3. length: 50mm-6000mm

4. Thickness: 2.0-10mm

wire products manufactured by Filter Solutions include:

Flat Screens

Support Grids

Candle Filters

• Cartridges

• Nozzles

Resin Traps

Screen Lateral Systems

Fractal Collectors and

Distributors

Sieve Bends and Boxes

Cylindrical Baskets

Conical Baskets

Pressure Screens

Screw Press Screens

The features of Welded wedge wire candle filter

1. Welded wedge wire candle filter has high flow rate, large open area and long lasting.

2. Welded wedge wire candle filter has“ V” shaped profile wire and avoids clogging.

3. Welded wedge wire candle filter is self-cleaning and ensures an uninterrupted flow.

industry applications of Welded Wedge Wire Candle Filter

Water and waste water

Pulp and paper

Chemical

Petrochemical

• Water Supply

Mineral and aggregate pro-

cessing

Plastics extrusion

Machine coolant filtration

Architectural applications

water well

• Construction

Drilling

Separating

• Filtering

• Media retention

• Sizing

• Dewatering

classifing

• Drying

Water Intake

• Fish diversion

• Backwashing

Centrifuges

• Floor Grating