Johnson Wedge Wire Filter Screen Nozzles in Precision Water Filtration

September 28, 2025

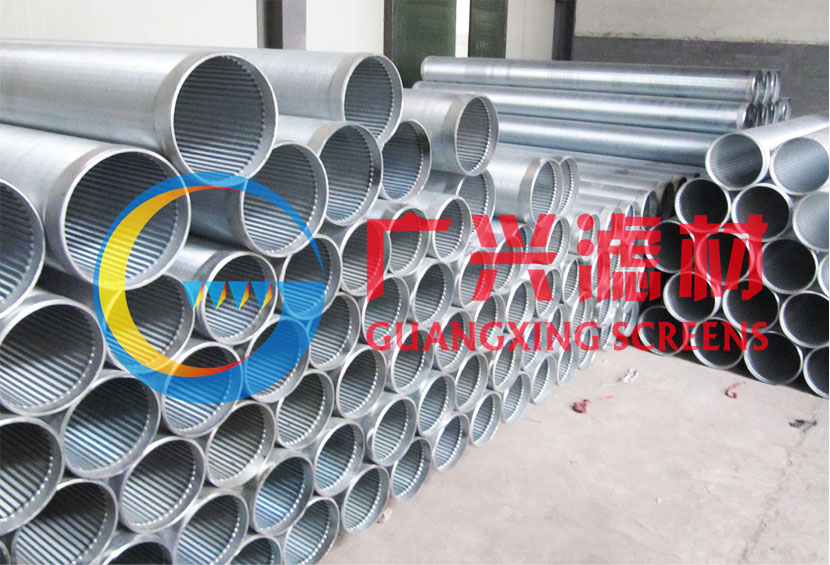

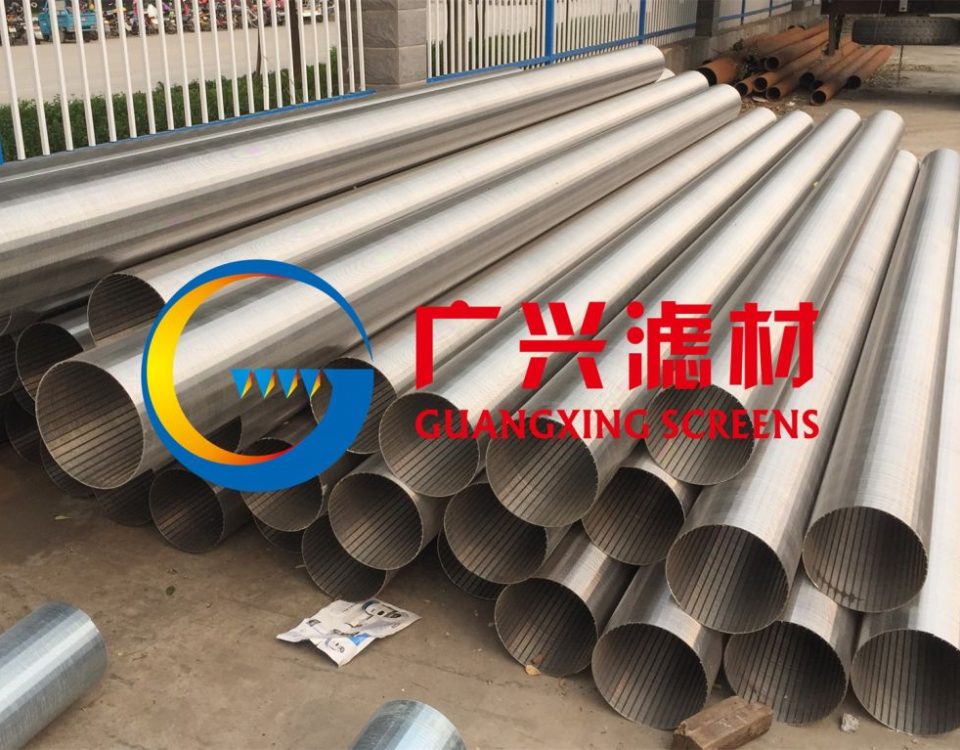

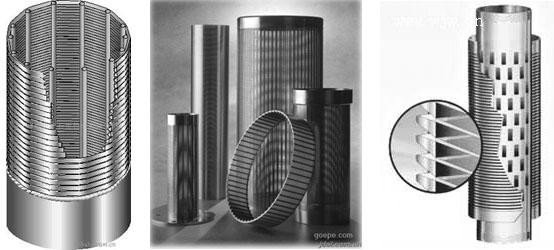

Stainless Steel Pipe Base Wire Wrapped Well Screens

October 4, 2025The Primary Hydraulic Advantage of V-Shaped Profile Wire in Continuous Slot Screens

The primary hydraulic advantage of the V-shaped profile wire used in Continuous Slot Screens is the establishment of a fundamentally non-clogging structure, which, in turn, cascades into superior, long-term hydraulic efficiency across diverse applications, most notably in water well, intake, and process filtration systems. This single geometric feature—the inward taper—solves the most critical operational problem associated with any filtration medium: the reduction of flow due to the wedging of particles. To fully appreciate this advantage, one must examine the specific mechanics of the wedge profile, compare it to conventional slot designs, and trace the resultant benefits through all stages of screen operation, from initial development to decades of continuous service.

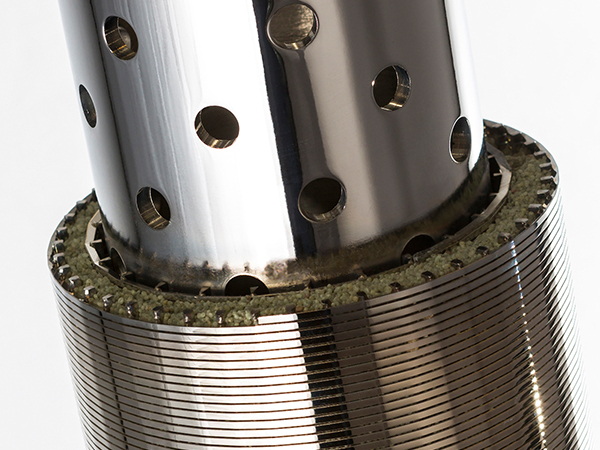

The Mechanism of Clog Resistance: The Inwardly Widening Slot

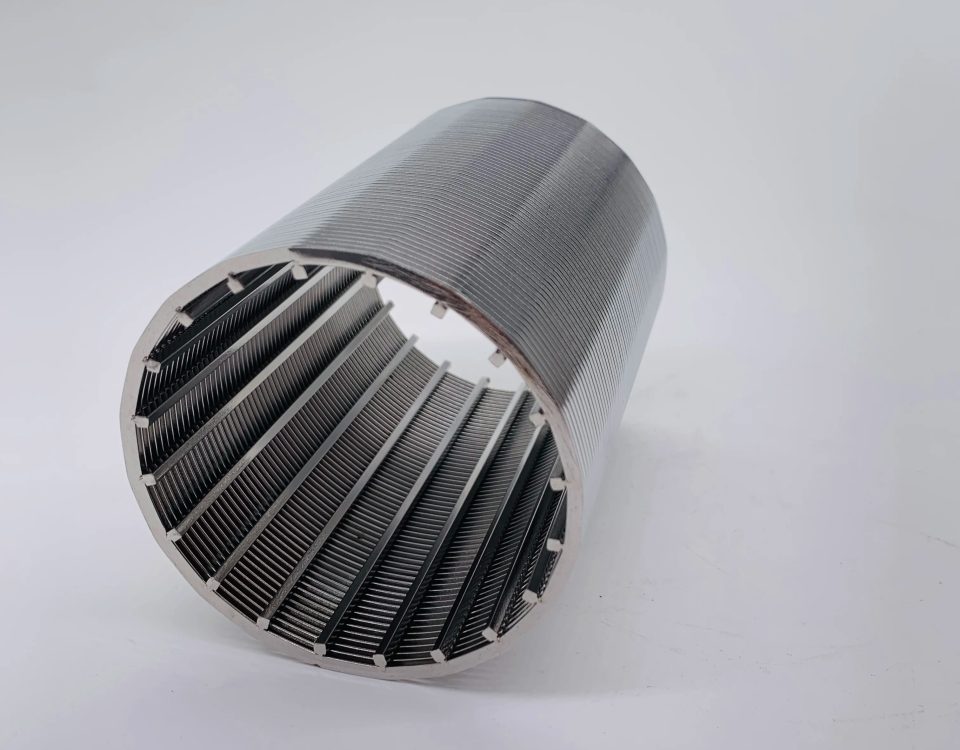

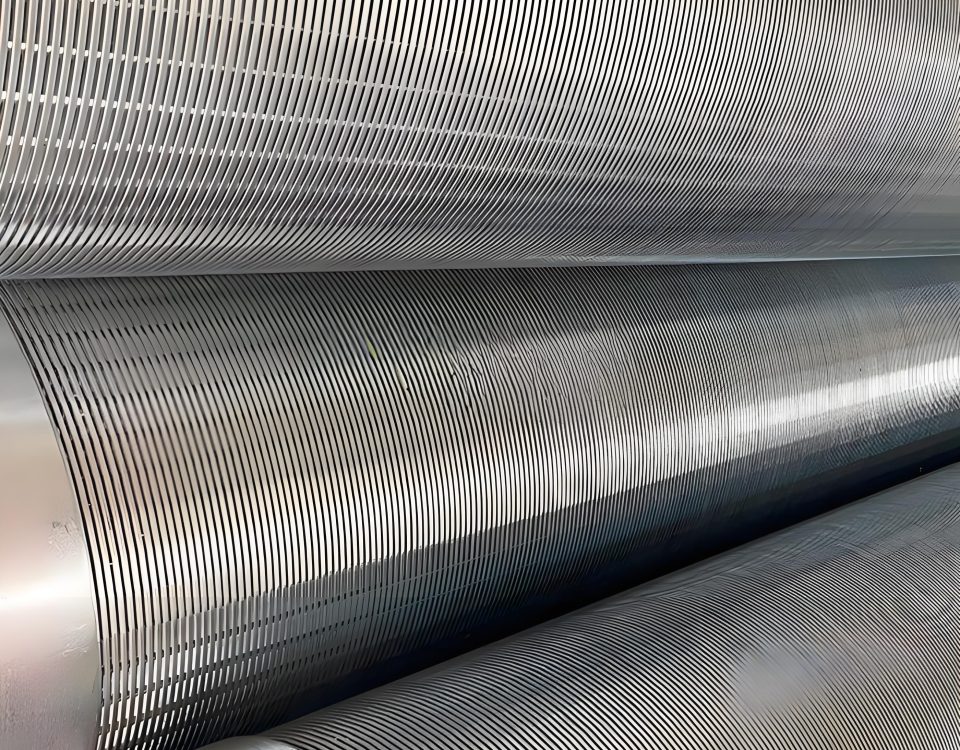

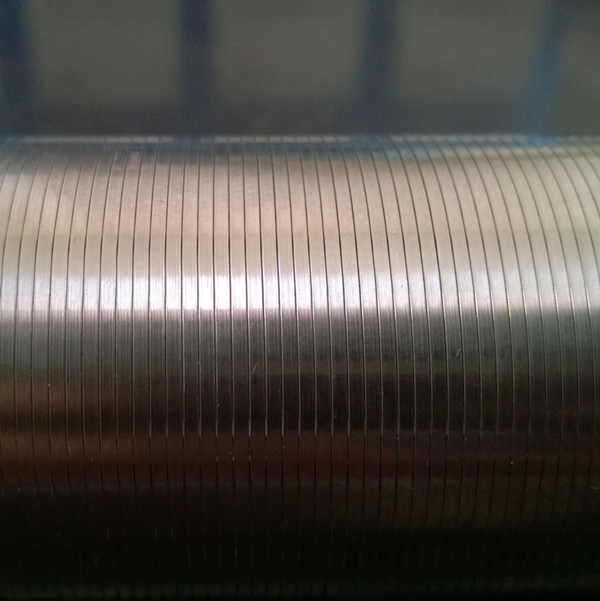

The $\text{V}$-shaped profile wire, also known as a wedge wire, is the foundational element of the continuous slot screen. This wire has a triangular or trapezoidal cross-section and is spirally wrapped around an array of longitudinal support rods. The resulting aperture, or slot, is defined by the pitch of the $\text{V}$-wires. Crucially, the $\text{V}$-wire is installed with the apex of the ‘$\text{V}$’ facing outward, meaning the slot opens wider as it progresses inward towards the screen’s interior diameter.

This geometric configuration creates the defining hydraulic property: the non-clogging slot.

A particle, such as a sand grain in a water well environment, approaching the screen must first pass through the narrowest point of the aperture. This point determines the nominal slot size. If the particle is slightly larger than this critical dimension, it is retained on the exterior face of the screen, where the smooth profile of the $\text{V}$-wire allows it to be easily washed away or remain lodged as part of the stable formation/gravel pack.

However, the genius of the $\text{V}$-wire design lies in what happens to particles that do manage to enter the slot. Because the slot aperture continuously widens in the direction of the flow (inward), any particle that passes the entry point is instantly in a channel that is larger than the particle itself. It is mathematically impossible for that particle to become wedged or pinched, as it would in a rectangular or square slot of equivalent size. In a rectangular slot, a particle that enters the opening can tumble or turn, lodging itself firmly across the constant width of the aperture, leading to rapid screen blinding and flow reduction. The $\text{V}$-slot design ensures that once a particle is cleared for entry, the path for its passage to the interior of the screen is clear and unimpeded.

This continuous geometric taper prevents the accumulation of material within the filter medium itself, guaranteeing a stable filtration surface area over the life of the screen.

Cascading Hydraulic Benefit I: Maximizing Open Area and Minimizing Entrance Velocity

The primary hydraulic advantage of non-clogging is intrinsically linked to two further critical hydraulic parameters: open area and entrance velocity ($\text{V}_e$).

Maximizing Effective Open Area

Continuous slot screens typically offer a much higher open area percentage compared to other designs, such as slotted pipe or bridge-slot screens. The open area is the total percentage of the screen surface available for water inflow. A high open area is achieved not just by the geometry of the continuous slot, but by the $\text{V}$-wire’s resistance to blinding.

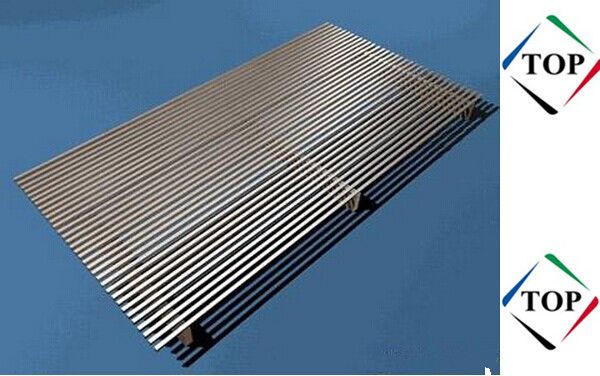

- Continuous Slot: Unlike drilled holes or milled slots, the $\text{V}$-wire is wound, creating a spiral slot that runs the entire length of the screen. This maximizes the physical open area.

- Sustained Open Area: The critical contribution of the $\text{V}$-shape is that it ensures this high physical open area remains an effective open area. A conventional screen may start with a decent physical open area, but if $50\%$ of its slots are blinded by wedged particles after a week, its effective open area drops drastically, leading to a catastrophic increase in hydraulic resistance. The $\text{V}$-wire’s non-clogging property maintains the screen’s original design hydraulic capacity.

Minimizing Entrance Velocity ($\text{V}_e$)

The relationship between effective open area ($A_o$) and entrance velocity ($V_e$) is fundamental to groundwater hydraulics and the longevity of the well:

where $Q$ is the flow rate (discharge) and $A_o$ is the effective open area.

By maximizing and sustaining the effective open area ($A_o$), the $\text{V}$-shaped screen successfully minimizes the entrance velocity ($V_e$) of the water flowing into the wellbore. Maintaining a low $V_e$ is paramount for several hydraulic reasons:

- Reduced Drawdown and Pumping Cost: Lower $V_e$ means less energy is dissipated as the water moves through the screen. This translates directly to reduced drawdown ($s$), which is the drop in the water level inside the well during pumping. Less drawdown means the pump has to lift the water a shorter distance, requiring less energy and significantly lowering long-term operational costs.

- Mitigation of Encrustation and Corrosion: High entrance velocities can cause localized pressure drops below the saturation vapor pressure of dissolved gasses (like $\text{CO}_2$), leading to the release of gas bubbles and a change in $\text{pH}$. This process accelerates the precipitation of minerals ($\text{CaCO}_3$, iron, manganese), leading to chemical encrustation on the screen surface. By keeping $V_e$ below the critical limit (often cited as $0.1 \text{ ft/s}$ or $3 \text{ cm/s}$), the $\text{V}$-wire screen significantly retards the rate of both biological and chemical fouling, thereby preserving the initial hydraulic performance for years.

- Preventing Screen Erosion: Extremely high velocities can physically erode the screen material over time, particularly in sand-heavy environments, causing the slots to widen and eventually fail to control the aquifer sand. Low $V_e$ preserves the integrity of the critical slot opening.

In essence, the hydraulic advantage starts with non-clogging, but the functional, measurable result is a sustainable, low entrance velocity which is the hallmark of an efficient hydraulic system.

Cascading Hydraulic Benefit II: Enhanced Well Development and Sand Control

In the context of water wells, the $\text{V}$-wire’s hydraulic superiority extends to the crucial process of well development and long-term sand control.

Facilitating Well Development

Well development is the hydraulic process of cleaning the filter pack and the formation surrounding the screen by introducing high-velocity surging and pumping to selectively remove the finer silt and clay particles while leaving a stable, coarser formation immediately adjacent to the screen.

The $\text{V}$-wire screen is inherently better suited for this process because its non-clogging nature allows for higher intensity development techniques (like surging, jetting, and air-lifting) without the risk of permanently plugging the screen. The $\text{V}$-slot allows the targeted fines to pass through without getting stuck, ensuring the well reaches its maximum potential specific capacity ($Q/s$). A screen that clogs during development will never achieve optimal hydraulic efficiency. The smooth internal flow path of the $\text{V}$-wire is designed to pass these fines with minimal friction until they are discharged from the well.

Optimized Sand Control

The $\text{V}$-wire screen is often used in conjunction with a gravel pack, a layer of uniformly sorted gravel placed between the screen and the natural formation. The screen acts as the final control barrier. The $\text{V}$-shape’s geometry enhances sand control in two ways:

- Stable Retention: The knife-edge contact of the $\text{V}$-wire with the sand grain minimizes the surface area where a particle can be held, but its sharp, precise slot size is highly effective at retaining the coarser filter pack material.

- Avoiding Bridging: The continuous, non-clogging slot ensures that the critical sand grains from the formation/gravel pack do not bridge (form an arch) across the opening and blind it prematurely. The screen only retains material that is truly oversized, allowing all other material to pass or remain settled in a stable configuration. This stability is a hydraulic advantage because an unstable formation can lead to continual fines production and the breakdown of the aquifer integrity.

Structural Integrity and Reverse-Flow Hydraulics

While the primary advantage is hydraulic, the manufacturing process that creates the $\text{V}$-wire screen’s exceptional strength is directly related to its sustained hydraulic performance. The profile wire is continuously welded to the support rods at every intersection point. This creates a homogeneous, robust, cage-like structure that resists the massive compressive and tensile forces encountered during installation and operation.

- Resistance to Collapse: High-performance screens must withstand significant pressure differentials (hydraulic collapse loads) from the formation during pumping or when the well is dewatered. Structural failure would instantly result in catastrophic hydraulic failure (e.g., uncontrolled sand influx). The $\text{V}$-wire screen’s integral welded construction ensures the slot size remains absolutely uniform and the screen does not deform under pressure, thus maintaining the original, high-efficiency hydraulic geometry.

- Reverse-Flow (Backwashing) Efficiency: In industrial and process filtration (e.g., intake screens, resin traps, carbon media filters), the $\text{V}$-wire design facilitates vastly superior backwashing or back-flush cleaning cycles—a reverse hydraulic function. Because the slot widens in the direction of forward flow, it narrows in the direction of reverse flow. When a powerful reverse pulse is applied, the $\text{V}$-shape acts as an accelerating nozzle. The smooth, minimal-contact surface, combined with the inwardly narrowing slot for reverse-flow, allows trapped particles on the outer surface to be easily lifted and expelled with minimal pressure, restoring the filter’s hydraulic capacity rapidly and completely. This efficient cleaning mechanism is a direct hydraulic consequence of the $\text{V}$-wire geometry.

The Ultimate Hydraulic Outcome: Maximizing Specific Capacity

The cumulative effect of the $\text{V}$-wire’s non-clogging geometry, high sustained open area, and resulting low entrance velocity is the optimization of a well’s specific capacity ($\text{C}$), which is the most definitive metric of hydraulic efficiency.

where $Q$ is the stable flow rate and $s$ is the drawdown.

A $\text{V}$-wire screen maximizes the numerator ($Q$) by maintaining the flow path and minimizes the denominator ($s$) by reducing head loss. In comparison to screens of equivalent length, diameter, and nominal slot size, the continuous slot $\text{V}$-wire screen often delivers a specific capacity that is significantly higher than that of conventional screens because it minimizes the component of drawdown attributable to head loss across the screen itself (known as screen loss or skin loss).

In conclusion, the $\text{V}$-shaped profile wire transforms a filtration medium from a potential flow bottleneck into a hydrodynamically efficient component. Its primary hydraulic advantage is the inherent non-clogging property, established by the inwardly widening slot. This core characteristic is the essential catalyst that enables all other desirable hydraulic outcomes: maximum sustainable open area, critically low entrance velocity, reduced drawdown, minimized encrustation, prolonged well life, and superior backwashing capability—all converging to ensure the highest possible long-term specific capacity and the lowest operational pumping cost.