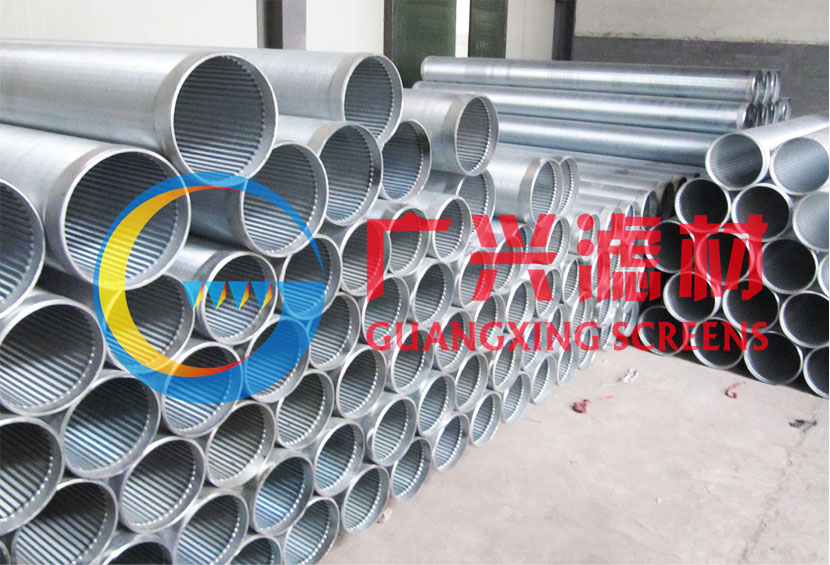

Stainless Steel Well Screens Manufacturing Processes

September 9, 2025

Johnson Well Screen Stainless Steel Drilling Pipe

September 20, 2025The Essential Guide to Water Well Screen Filter Pipes: Engineering the Lifeline for Pure Water

Abstract

The extraction of clean, sustainable groundwater is a critical endeavor for countless industries and municipalities worldwide. At the very heart of a successful water well system lies a component whose importance cannot be overstated: the well screen. Far more than a simple pipe, the well screen is a precision-engineered filter, the primary interface between the aquifer and the well. Its design and material selection directly dictate the well’s efficiency, longevity, and water quality. This comprehensive guide delves into the world of water well screen filter pipes, with a specific focus on the advanced technology of stainless steel wedge wire screens. We will explore their construction, materials, key parameters, and vast applications, providing a detailed comparative analysis to inform selection for optimal performance and return on investment.

1. Introduction: The Role of the Well Screen

A well screen is a filtering device installed at the intake section of a water well. Its core functions are:

- Facilitating Water Entry: To allow water from the aquifer to flow freely into the well.

- Filtering Sediment: To prevent sand and fine aquifer materials from entering the well, which protects the pump from abrasion, prevents well clogging, and ensures sediment-free water.

- Supporting the Formation: To provide structural support for the unconsolidated aquifer formation around the well bore, preventing collapse.

A poorly chosen or manufactured screen is a leading cause of well failure, resulting in diminished yield, sand pumping, frequent maintenance, and a significantly shortened operational lifespan. Therefore, selecting the right screen is not a matter of cost, but of long-term value and performance.

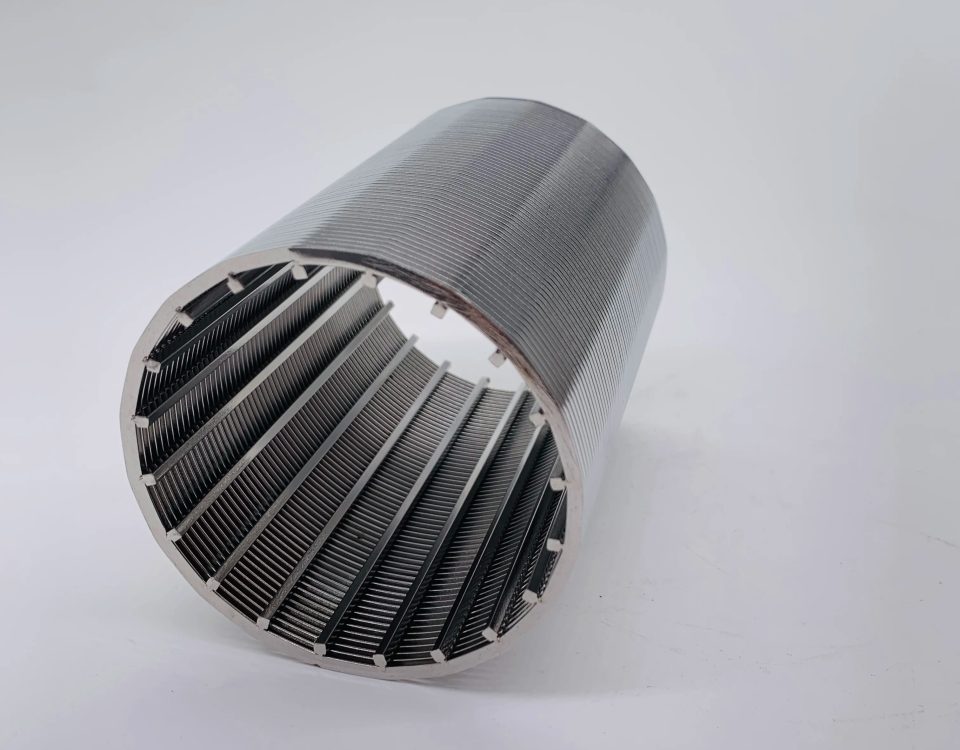

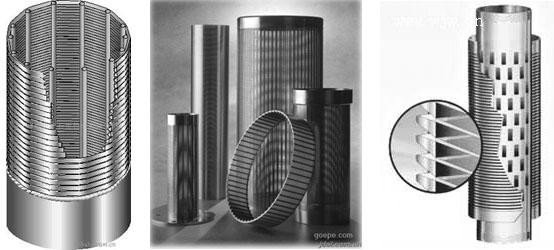

2. Unveiling the Technology: Wedge Wire Construction

The provided specifications point to a premium category of well screens: those manufactured using the wedge wire technique. This design is superior to traditional slotted or perforated pipes for most demanding applications.

What is Wedge Wire?

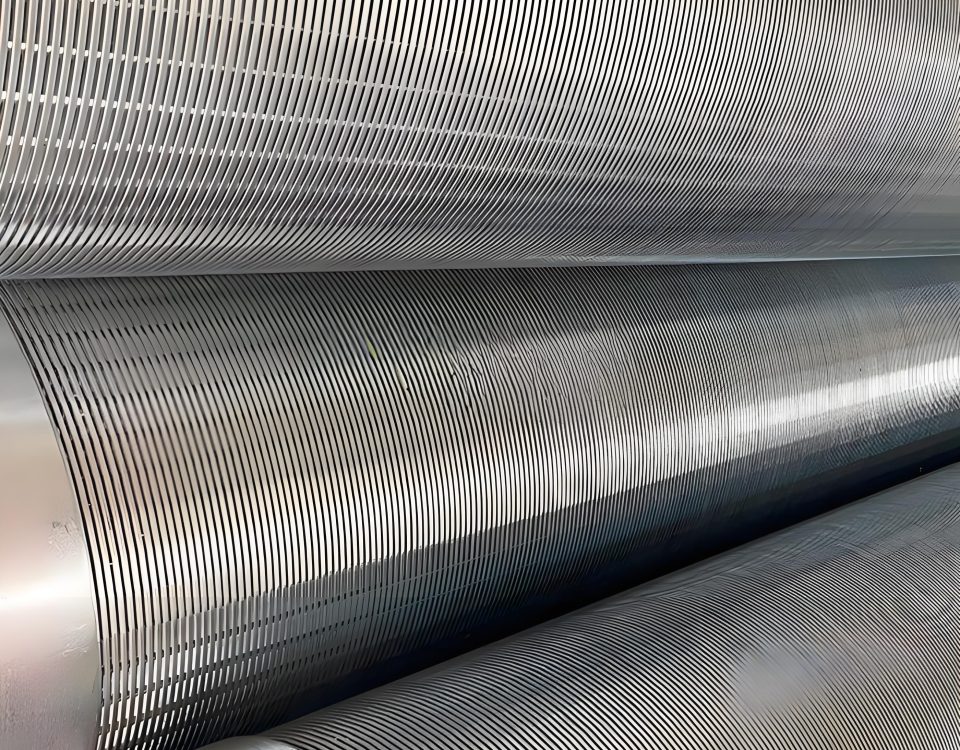

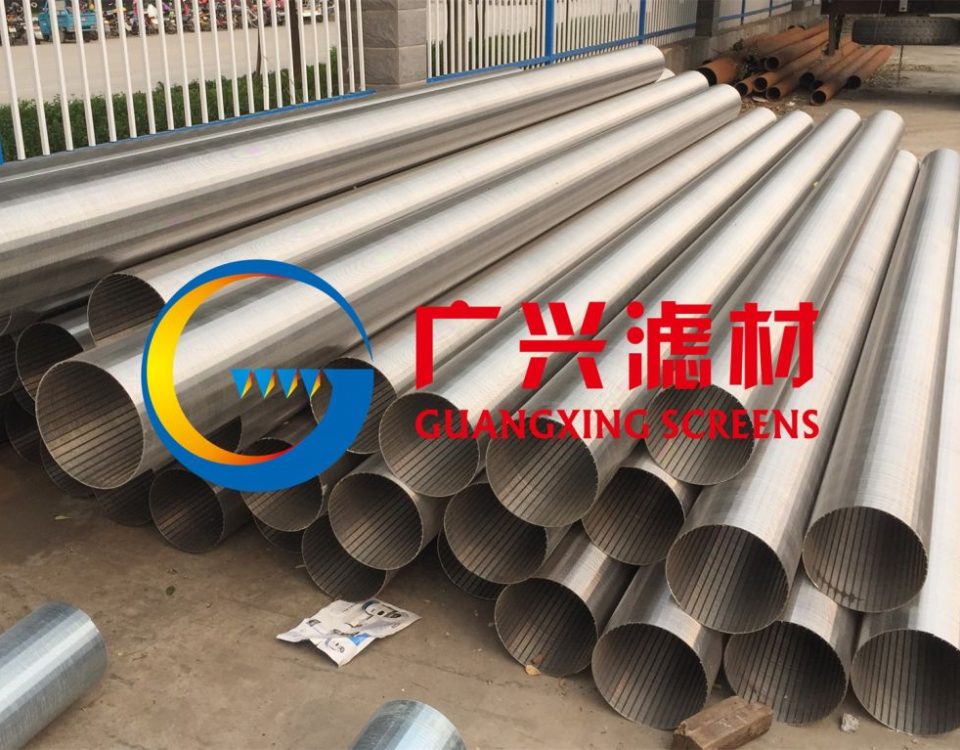

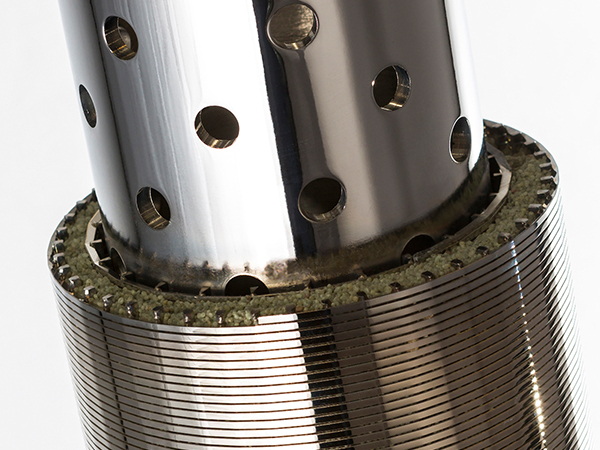

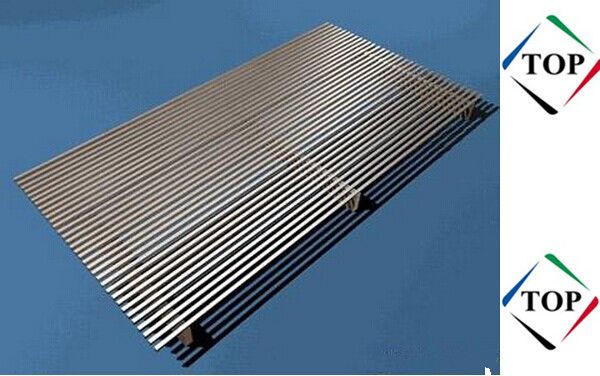

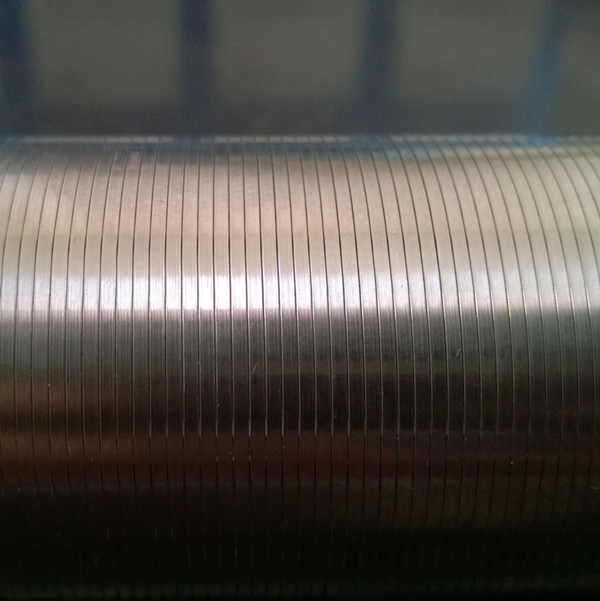

A wedge wire screen is constructed from profile wires (wires with a trapezoidal cross-section) welded onto a robust internal support frame, typically vertical rods. The profile wires are spaced with extreme precision to create continuous, uniform slots running the length of the screen.

Why is this Design Superior?

- V-Shaped Slot (The Wedge): The trapezoidal wire creates a slot that is narrow on the outer face and widens inward. This V-shaped profile is inherently non-clogging. Particles smaller than the slot pass through, while those larger than the opening are rejected. If any particles do lodge in the opening, the widening internal profile allows them to be easily dislodged by backwashing or natural flow reversals.

- High Open Area: Wedge wire screens offer a much higher percentage of open area (the total surface area of the slots) compared to drilled or punched screens. A higher open area means less resistance to flow (lower entrance velocity), which reduces drawdown in the well and increases efficiency. This also minimizes the risk of incrustation (mineral buildup) and biofouling.

- Strength and Durability: The continuous weld along the length of each support rod creates an exceptionally strong, rigid, and robust cylinder capable of withstanding high pressures and installation stresses without deforming.

3. Deep Dive into Key Parameters and Specifications

The performance of a well screen is defined by its precise specifications. Let’s break down the provided parameters.

1. Material: The Foundation of Longevity

The choice of material is paramount and depends entirely on the chemistry of the groundwater and the intended application.

- Stainless Steel 304: An excellent general-purpose, corrosion-resistant alloy. Suitable for most freshwaters with a near-neutral pH. It offers a great balance of performance and cost.

- Stainless Steel 316: Contains molybdenum, which significantly enhances its resistance to chlorides and pitting corrosion. It is the mandatory choice for brackish water, saltwater environments (like sea water desalination intake), or aggressive industrial applications.

- Low Carbon Steel (e.g., AISI 1010/1018): Used for its high tensile strength and lower cost. It is almost always used with a protective coating, such as epoxy, vinyl, or galvanization, to prevent rust and corrosion. Ideal for temporary wells, certain oil and gas applications, or large-diameter dewatering projects where fluid corrosivity is low and cost is a major factor.

2. Slot Size: The Precision Filter

The slot opening, measured in millimeters or inches, is the most critical sizing parameter. It must be chosen based on a sieve analysis (grain size distribution) of the aquifer formation.

- Common Openings: 0.5mm, 0.75mm, 1mm, and 1.5mm (as provided) are standard for finer sands. A wide range is available, from very fine (0.10mm) to coarse (3.0mm+).

- Selection Rule: The slot size is chosen to retain a significant portion (typically 40-60%) of the aquifer formation. An engineer will analyze the sand sample and select a slot size that corresponds to the 40th-50th percentile (D40/D50) of the grain size distribution. Choosing the correct slot is essential for creating a stable, naturally filtering gravel pack around the screen.

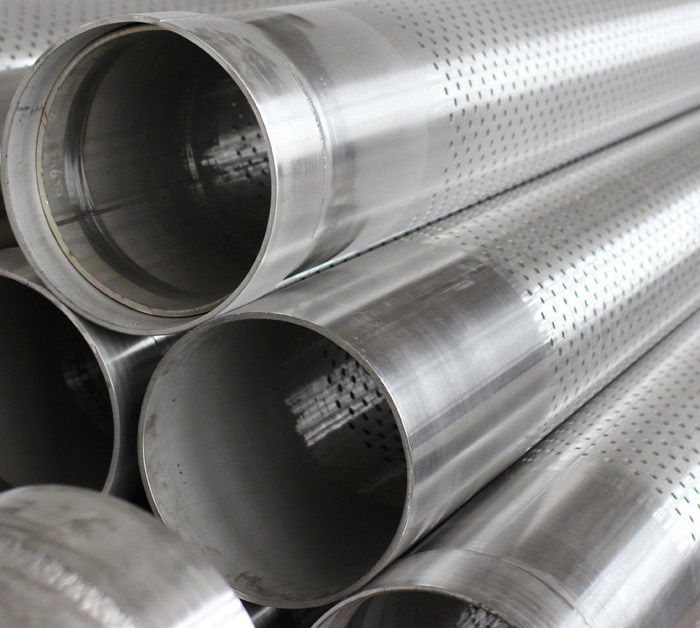

3. Diameter and Length: The Dimensions of Capacity

- Outside Diameter (OD): Standard sizes like 4″, 6″, 8″, 10″, and 12″ are common, but wedge wire screens can be fabricated in very large diameters (e.g., 24 inches or more) for municipal and industrial high-yield wells. The 9 5/8″ specification is a common size in the oil & gas industry.

4. End Finishing: The Connection System

The end finishing allows the screen to be integrated into the well string.

- Thread Fitting (Box/Pin): Standard threaded ends that screw directly onto the pump housing or plain pipe. Common for smaller diameter wells.

- Flange: A flat, circular rim with bolt holes welded to the end of the screen. Allows for a strong, bolted connection to other flanged components. Used for large-diameter wells.

- Closed Plate & Metal Ring: These are often used to create a blank section (to seal off an aquifer) or to provide a solid base cap at the bottom of the screen. A metal ring can be added for additional strength at the connection point.

4. Comparative Analysis: Choosing the Right Screen

The following table provides a detailed comparison of the key screen types based on the provided parameters and beyond.

Table 1: Comprehensive Parameter Comparison of Well Screen Types

| Parameter | Wedge Wire Screen (SS 304/316) | Wedge Wire Screen (Coated Carbon Steel) | Perforated Pipe Screen | Slotted Pipe Screen | Continuous Slot Screen (Bridge Slot) |

|---|---|---|---|---|---|

| Primary Material | Stainless Steel 304/316 | Low Carbon Steel (Epoxy/Vinyl Coated) | Mild Steel, Stainless Steel, PVC | Mild Steel, Stainless Steel, PVC | Stainless Steel, Galvanized Steel |

| Slot Precision | Excellent. Laser-set, uniform, consistent. | Excellent. Laser-set, uniform, consistent. | Poor. Irregular, burred. | Fair. More uniform than perforated. | Very Good. Mechanically cut, consistent. |

| Open Area | Very High (20% – 40%) | Very Low (1% – 5%) | Low (2% – 8%) | Moderate (10% – 15%) | |

| Anti-Clogging | Excellent. V-shaped slot design. | Excellent. V-shaped slot design. | Poor. Liable to plugging. | Fair. Prone to plugging. | Good. |

| Corrosion Resistance | Excellent (316), Very Good (304) | Good (Dependent on coating integrity) | Varies by material | Varies by material | Varies by material |

| Strength/Durability | Very High. All-welded construction. | Very High. All-welded construction. | High (if thick-walled) | Moderate | Moderate to High |

| Cost Factor | High | Medium-High | Low | Low | Medium |

| Ideal Application | Critical water supply, aggressive environments, high flow. | Large-diameter dewatering, oil/gas, cost-sensitive projects. | Very rough, temporary applications, low priority wells. | Budget-conscious, low-yield domestic wells. | General purpose municipal & industrial wells. |

5. Applications Across Industries

The provided list of applicable industries highlights the versatility of this technology:

- Energy & Mining: Used for dewatering mines, extracting process water, and in-situ leaching. Their strength and resistance to abrasion from sandy water are critical.

- Oil Filtration: Used in intake screens for water injection wells and filter vessels within production facilities.

- Sea Water Desalination: 316 stainless steel is mandatory for intake screens that draw ocean water, resisting the highly corrosive saltwater environment.

- Beer/Beverage Equipment: The food-grade quality of 304 and 316 stainless steel makes them perfect for filtration steps in brewing, ensuring no contamination or corrosion affects the product taste.

- Beyond the List: Municipal water supply, agricultural irrigation, geothermal wells, environmental monitoring wells, and construction dewatering.

6. The Criticality of Features: Pressure, Temperature, and Inclined Shafts

The mentioned features are not just marketing points; they are engineered solutions:

- High Pressure: The all-welded, monolithic construction of a wedge wire screen can be designed to withstand extreme external pressures from deep aquifers or internal pressures from well development procedures like surging or jetting.

- High Temperature: Stainless steels 304 and 316 retain their strength and corrosion resistance at elevated temperatures, making them suitable for geothermal applications or industrial processes involving hot fluids.

- Inclined Shaft Environments: Installing a screen in a directionally drilled well (not vertical) places immense stress on the joints. The high strength and rigidity of wedge wire screens prevent buckling and deformation during installation in these challenging well bores.

7. Conclusion: An Investment in Performance and Longevity

Selecting a water well screen filter pipe is a fundamental engineering decision with decades-long consequences. While initial costs for advanced wedge wire screens are higher than for simpler alternatives, this investment is quickly justified through superior performance.

The benefits are clear: maximized well yield through high open area, elimination of sand pumping through precise slot control, extended well life through superior corrosion and clogging resistance, and reduced maintenance costs over the asset’s lifetime.

By understanding the specifications—from the critical choice between 304 and 316 stainless steel to the precision of the slot opening and the strength of the end finishing—engineers and project managers can specify the optimal screen. This ensures that the well, the most critical asset in the water extraction system, remains a reliable and prolific source of water for years to come. In the world of water well technology, the screen is not just a component; it is the guardian of the well’s integrity and the guarantor of its output.