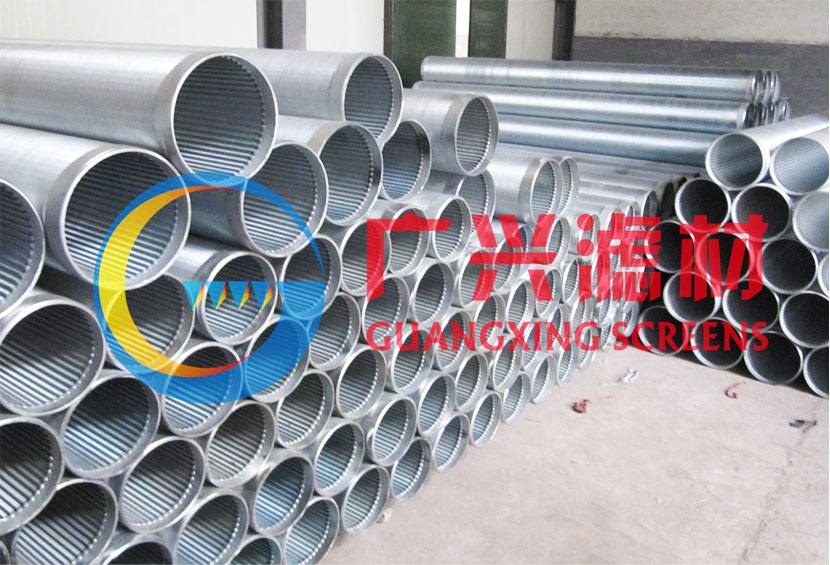

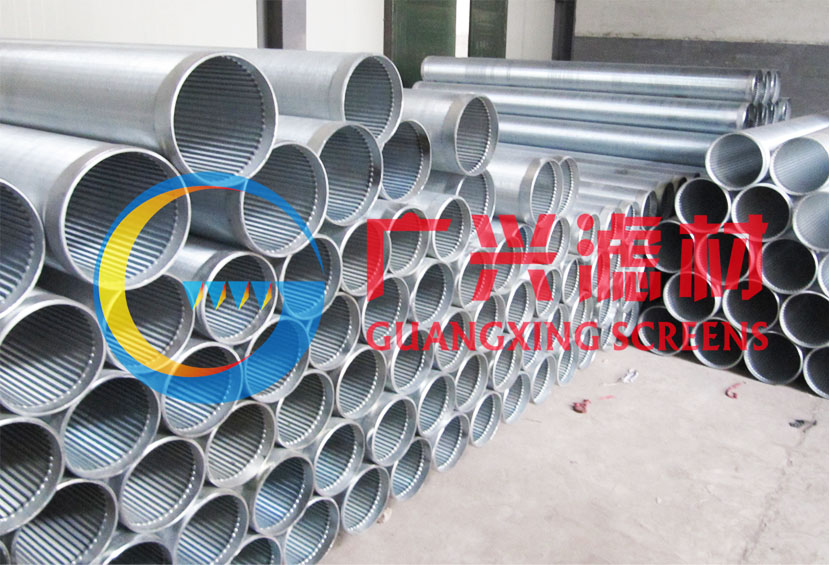

Johnson Screens stainless steel well screens

December 6, 2017

intake traveling water screen and Drum Intake Screens

December 8, 2017Johnson Screens’ solution for improving the gravel pack — the Muni-Pak screen. For contractors, this state-of-the-art, pre-packed screen eliminates the need for a larger borehole, shortens the time required to drill a well and speeds development time. It simplifies the contractor’s work and improves successful well development.

For the well owner, the Muni-Pak screen offers long-term benefits. This innovation uses ceramic or glass beads as the filter media — a concept that reduces the likelihood of filter pack fouling from biofilm and encrustation, lowering overall well maintenance costs.

Johnson Screens’ solution for improving the gravel pack — the Muni-Pak screen. For contractors, this state-of-the-art, pre-packed screen eliminates the need for a larger borehole, shortens the time required to drill a well and speeds development time. It simplifies the contractor’s work and improves successful well development.

For the well owner, the Muni-Pak screen offers long-term benefits. This innovation uses ceramic or glass beads as the filter media — a concept that reduces the likelihood of filter pack fouling from biofilm and encrustation, lowering overall well maintenance costs.

Utilizes a smaller borehole

Eliminates gravel placement

Shortens the amount of time required to drill a well

Reduces development time

Has a thinner filter pack

Reduces overall maintenance costs

Muni-Pak Screen Specifications

| xz | xz | xz | xz |

Inner Screen Open Area – |

Outer Screen Open Area – |

|||||||||||||

| Size¹ (in.) |

Approx. Screen ID (in.) |

Approx. Screen OD (in.) |

Media Annular Thickness (in.) |

Screen Slot Size |

Screen Slot Size |

Approx. Screen Weight (lbs/ft.) |

||||||||||||

| xz | xz | xz | xz |

8 |

12 |

20 |

25 |

30 |

40 |

50 |

8 |

12 |

20 |

25 |

30 |

40 |

50 |

x |

|

2 x 4 |

2.2 |

4.5 |

0.85 |

11 |

15 |

22 |

26 |

30 |

36 |

41 |

20 |

28 |

42 |

50 |

57 |

68 |

77 |

17 |

|

3 x 5 |

3.0 |

5.7 |

0.97 |

16 |

22 |

33 |

39 |

44 |

53 |

60 |

25 |

36 |

54 |

63 |

72 |

86 |

98 |

23 |

|

4 x 6 |

4.0 |

6.7 |

0.94 |

20 |

28 |

42 |

50 |

57 |

68 |

77 |

30 |

42 |

63 |

74 |

84 |

101 |

115 |

25 |

|

5 x 7 |

5.0 |

7.7 |

0.87 |

25 |

35 |

53 |

62 |

71 |

85 |

96 |

34 |

48 |

73 |

85 |

97 |

116 |

132 |

27 |

|

6 x 8 |

6.0 |

8.7 |

0.84 |

20 |

29 |

45 |

54 |

62 |

77 |

89 |

27 |

39 |

60 |

71 |

82 |

101 |

117 |

35 |

|

8 x 10 |

8.0 |

10.8 |

0.84 |

27 |

38 |

59 |

71 |

81 |

100 |

116 |

33 |

48 |

74 |

89 |

102 |

125 |

145 |

55 |

|

10 x 12 |

10.0 |

12.8 |

0.84 |

26 |

38 |

60 |

72 |

83 |

104 |

122 |

31 |

45 |

71 |

86 |

99 |

124 |

145 |

70 |

|

12 x 15 |

12.0 |

15.0 |

0.84 |

31 |

45 |

71 |

85 |

99 |

123 |

145 |

36 |

53 |

83 |

100 |

116 |

145 |

170 |

85 |

|

14 x 16 |

13.2 |

16.0 |

0.64 |

36 |

52 |

81 |

98 |

113 |

141 |

165 |

41 |

59 |

93 |

112 |

129 |

161 |

188 |

100 |

|

16 x 18 |

15.2 |

18.0 |

0.64 |

41 |

59 |

93 |

112 |

129 |

161 |

188 |

46 |

67 |

104 |

126 |

145 |

181 |

212 |

115 |

|

18 x 20 |

17.0 |

20.0 |

0.78 |

39 |

57 |

90 |

109 |

127 |

160 |

188 |

44 |

64 |

101 |

122 |

141 |

177 |

209 |

128 |

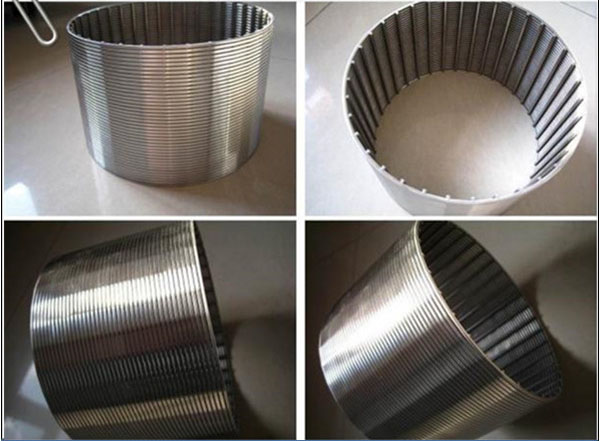

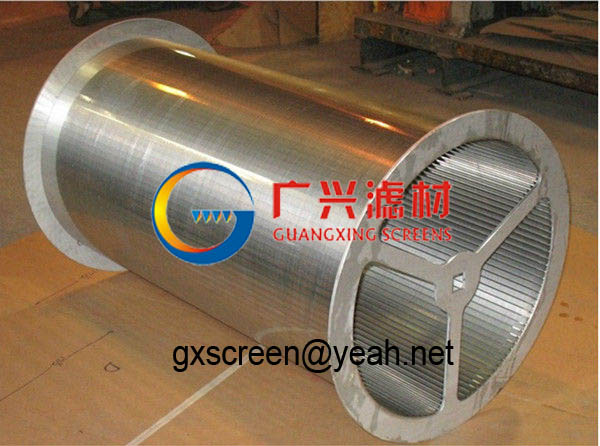

The Muni-Pak’s dual-screen construction is four times stronger than standard rod-based screens, allowing more aggressive development and better immunity to unexpected hole problems—providing lower costs.

Applications of stainless steel muni-pak screen

Controls sand infiltration in new, high-capacity municipal, industrial and agricultural wells

Can be used as a liner in existing wells to eliminate the need for constructing a new well

Custom applications such as infiltration galleries

Environmental remediations

Horizontal applications

The Muni-Pak’s dual-screen construction is four times stronger than standard rod-based screens, allowing more aggressive development and better immunity to unexpected hole problems—providing lower costs.

Muni-Pak works great as a liner in existing well construction, eliminating the need the construction and the cost of a new.

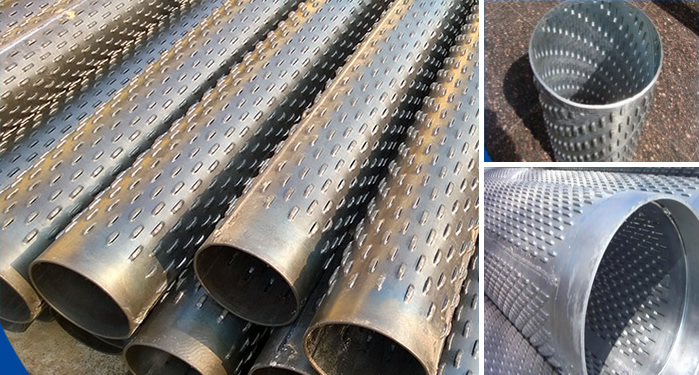

filter pack is one of the most common designs used today for high-capacity municipal, industrial and agricultural wells. Before the installation of a filter pack, the contractor and the well owner must take into account some significant issues:

- The borehole must be sufficiently oversized to allow for adequate placement of the filter pack. In practice, an annular thickness of 3 to 5 in. is considered minimum. The oversized borehole is costly to the contractor (and therefore to the well owner) and keeps the crew on site for additional time.

- The filter pack must be carefully selected, placed and developed to avoid bridging and sand pumping.

- The well owner is concerned with long-term performance. Biofouling and encrustation are issues that will eventually affect performance.