How to select Water well screen for filter : Method of selecting well screen

December 31, 2017

Why Wedge Wire For Well Screen?

January 16, 2018

The Foundation of Exploration and Utilization: High-Performance Wedge Wire Well Screens

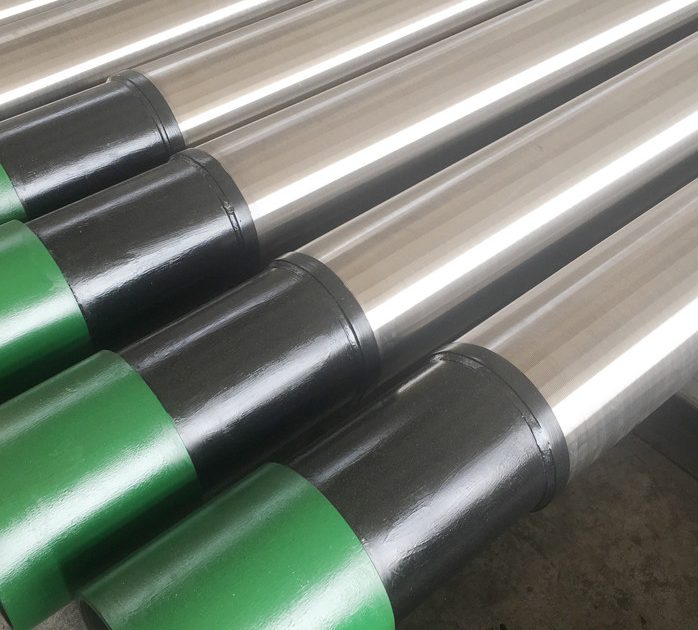

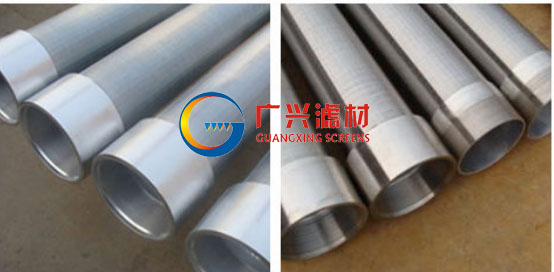

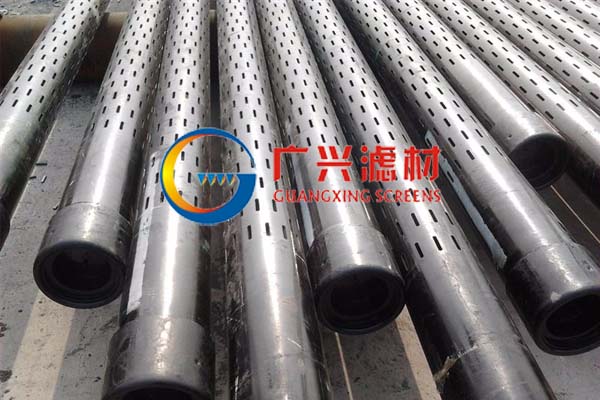

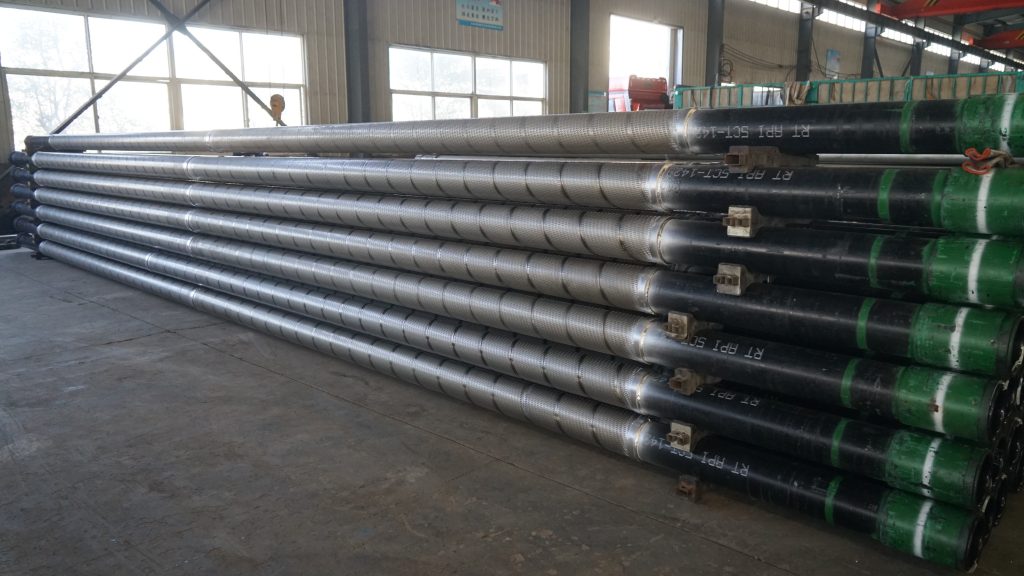

In the fields of water resource development, oil and gas extraction, and critical industrial filtration, the Wire Wrapped Well Screen (Wedge Wire Screen) is the core component that ensures clean fluid media, safeguards equipment, and maintains long-term production. As the crucial interface between the wellbore and the formation, its performance directly determines the lifespan and efficiency of oil wells, gas wells, and water wells.

Our company is committed to providing industry-leading Wedge Wire Screen / Wire Wrapped Screen product lines. Through innovative V-Shaped Continuous Slot design and a comprehensive All-Welded Structure, we completely solve the core issues of clogging, insufficient strength, and short lifespan faced by traditional filtration equipment. Our screens stand out with their exceptional corrosion resistance, high open area, and precise slot dimensions, making them the ideal choice for various media filtration applications.

I. Product Overview and Structural Principle

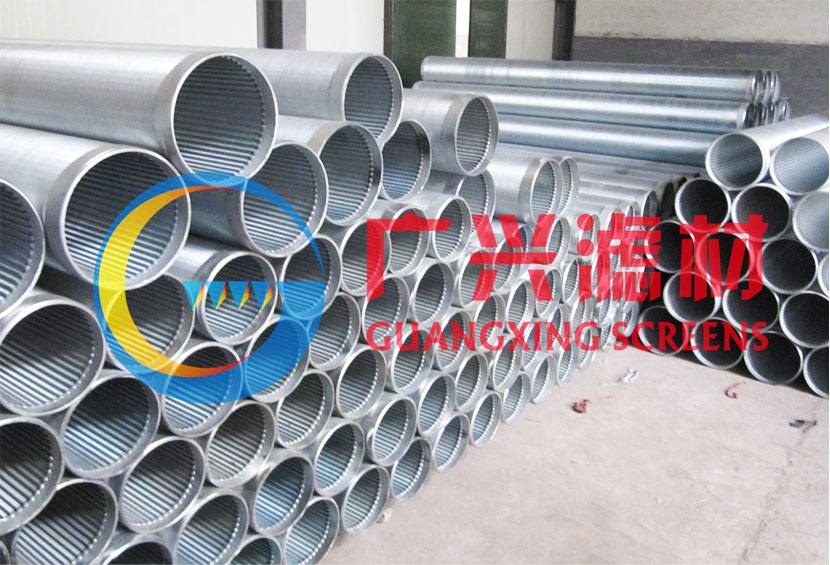

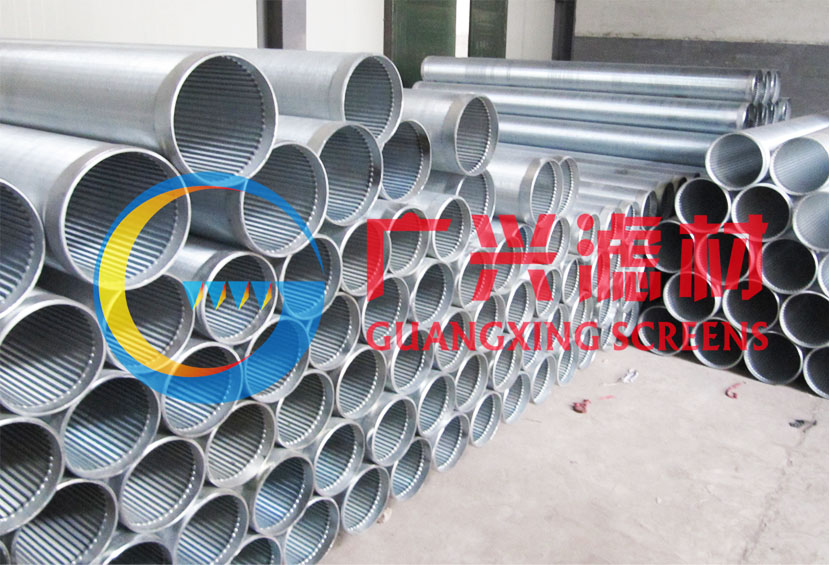

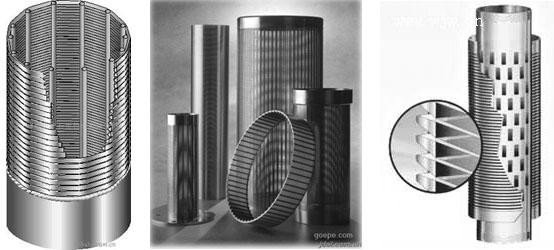

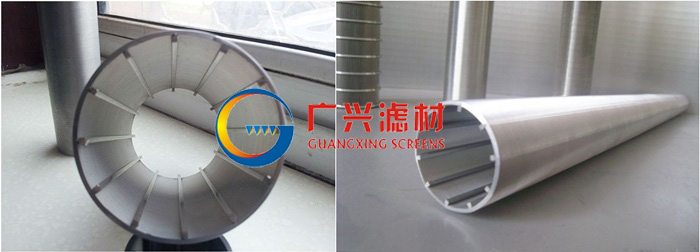

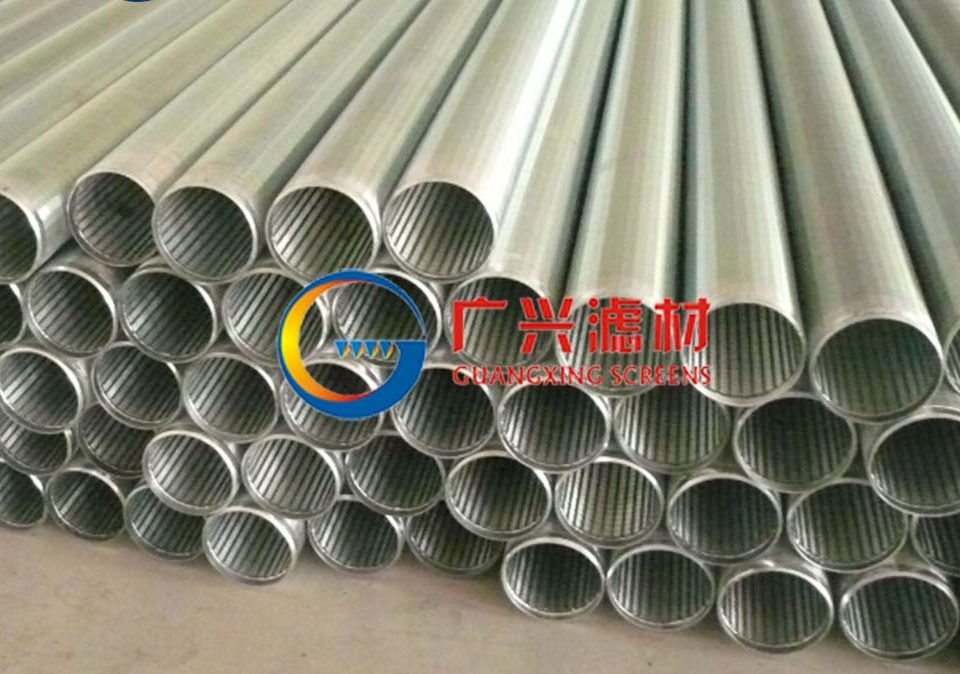

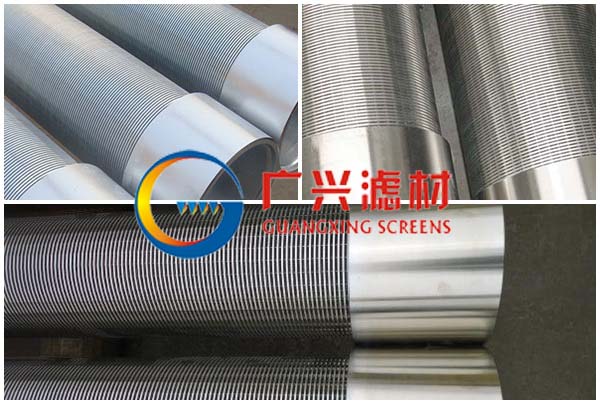

Our well screens, also known as wedge wire screens or wire wrapped screens, are high-performance filtering water pipes. They are formed by fusing structural rods and the surrounding **wedge wire** through a precise welding process, creating a filter medium that is both robust and highly efficient.

1. Structural Features: All-Welded and Trapezoidal Wire Design

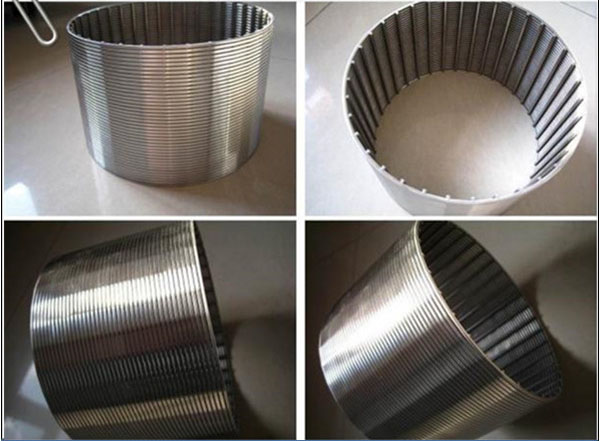

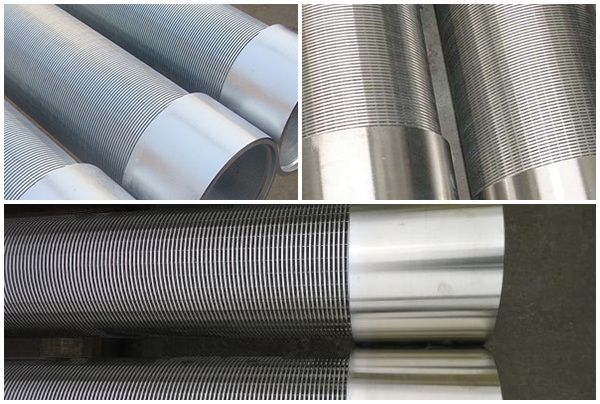

The well screen jacket (or screen) consists of Rods (Support Rods) and Warp Wires (Profile Wires). These are rigidly fused together using electric fusion welding technology, guaranteeing the screen’s strength and the accuracy of the slot openings.

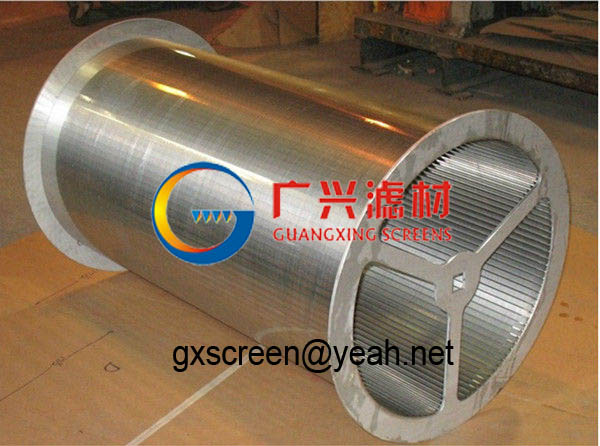

- Support Rods (Rod): The rods are the skeleton of the screen, providing axial and radial structural support. They can be made of **round wire, triangular wire, or trapezoidal wire** profiles, depending on the required strength and hydraulic characteristics.

- Warp Wires (Profile Wire): The warp wire is critical to the filtration function. We utilize the unique **Triangular Wire (V-Shaped Wire)** profile for the warp, which is the core design element that achieves the **non-clogging** characteristic.

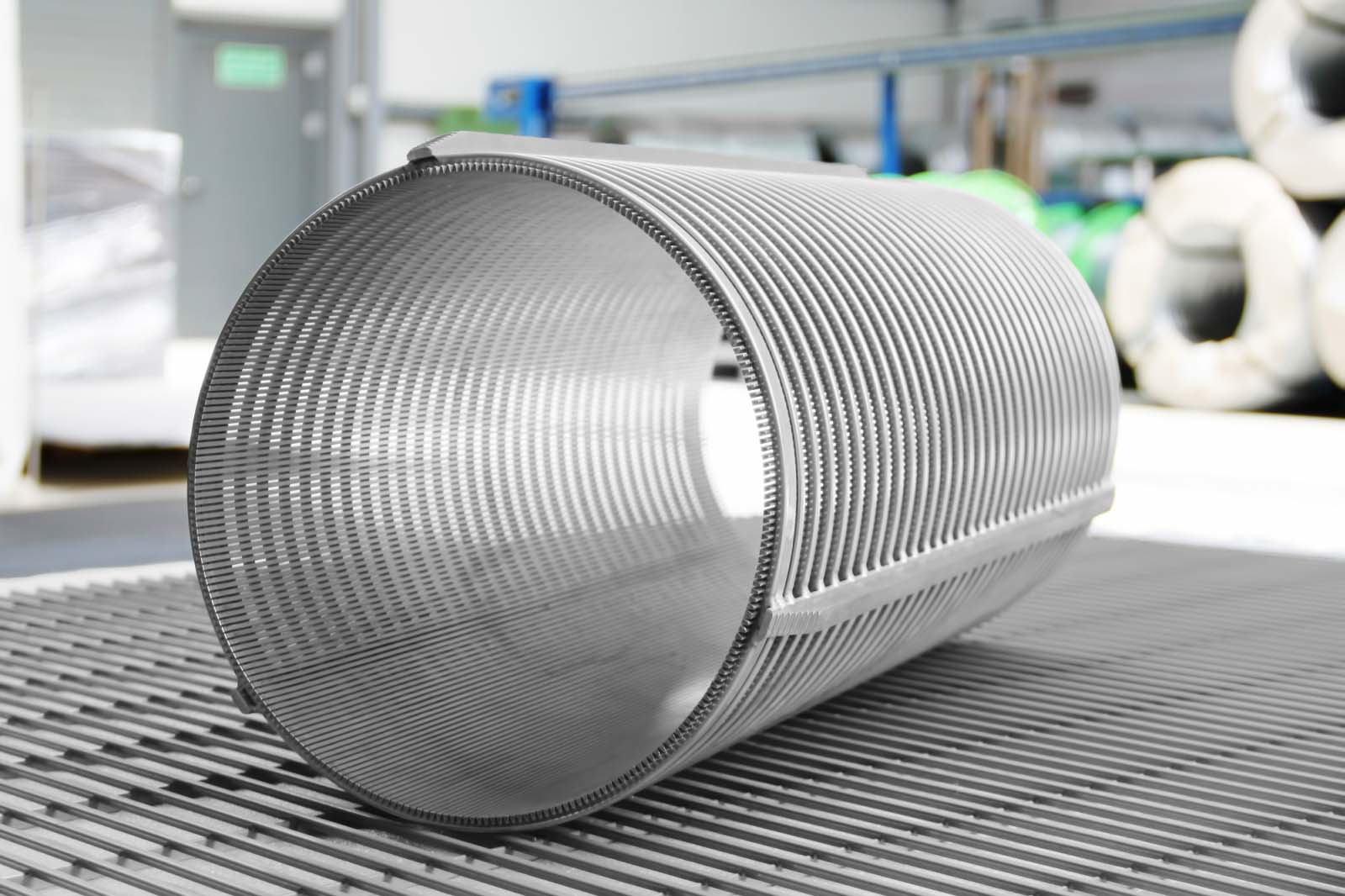

2. Core Advantage: The V-Shaped Continuous Slot

The slot created by welding the V-shaped (trapezoidal) profile wire to the support rods offers two decisive advantages:

- Continuous Slot Opening: The warp wire is helically wound along the entire length of the screen, ensuring a **continuous slot opening**. This significantly increases the **available open area** for fluid access into the aquifer, providing greater passage and maximizing flow rate or production.

- Non-Clogging Design: The slot opens wider in the direction of flow (from the outside surface inwards, due to the V-shape). Any particle that successfully passes the narrowest point of the slot will not get stuck or bridge in the wider channel inside the screen. This **reverse-slope design** avoids clogging, ensuring **uninterrupted flow** and long-term filtration efficiency.

II. Material Science and Corrosion Resistance

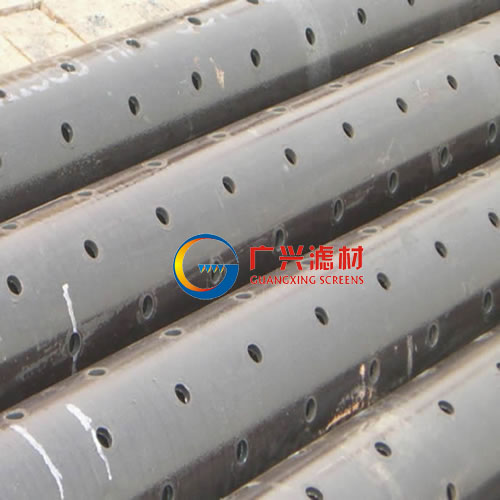

Since the screen must operate in complex media environments, material selection is the foundation for ensuring a **long service life, safety, and reliability**. We offer diverse options, ranging from basic carbon steel to a series of high-performance stainless steels.

| Material Type | Common Grades | Key Characteristics and Application Environment |

|---|---|---|

| Carbon Steel | Standard Carbon Steel | Cost-effective, suitable for non-corrosive, fresh water wells or industrial filtration where water quality is good. |

| Stainless Steel | 304 | Industry standard, suitable for general water wells and media filtration with low corrosion or no chloride contamination. |

| 304L | Low-carbon grade, offers better weldability and stronger resistance to intergranular corrosion, suitable for complex water treatment. | |

| 316 | Contains Molybdenum, significantly enhances **corrosion resistance**, especially against chloride attack, ideal for seawater desalination or coastal water wells. | |

| 316L | Superior to 316, the preferred choice for environments containing chlorides, acid/alkali media, or high temperatures. It is key to ensuring **good mechanical properties** and **safety/reliability**. |

Heat and Corrosion Resistance: Particularly in petrochemical and seawater desalination fields, media often contain acid/alkali solutions, salts, or organic solvents. Selecting Molybdenum-containing stainless steel like **316 / 316L** ensures the screen maintains its **stable mechanical properties** in these harsh environments, resisting pitting and crevice corrosion, thus greatly extending the equipment’s lifespan.

III. Engineering Advantages: High Open Area and Cost-Effectiveness

Our trapezoidal wire-welded screen achieves excellent engineering advantages through structural optimization, translating directly into **low-cost operations** and **low overall cost** for the customer.

1. Significantly Increased Open Area

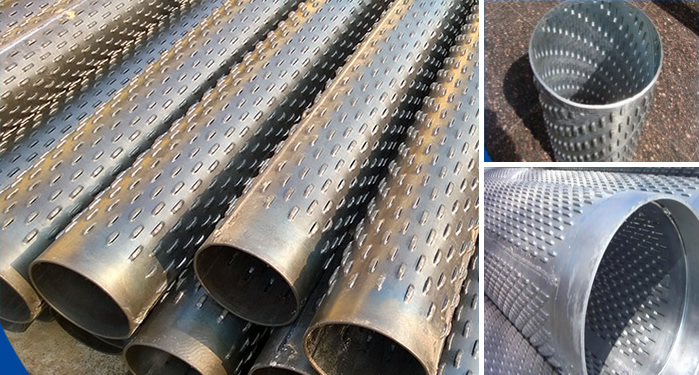

The **High Open Area** is one of the most critical performance indicators for well screens, measuring the effective area available for fluid entry. Our continuous slot design provides an open area that is several times higher than traditional bridge slot screens or perforated pipes.

- Uniform and Efficient Well Development: Due to the continuous slotting, the screen provides evenly distributed fluid entry points. This enables **uniform and efficient well development**, avoiding structural damage and wellbore collapse caused by local high-velocity fluid scouring the formation.

- Facilitates Groundwater Permeation: Screens with a high open area significantly improve **groundwater permeation** efficiency. Abundant water entry effectively **reduces the drawdown level**, thereby substantially **saving energy consumption** (submersible pumps don’t need to lift water from a greater depth).

2. Extending Well Life and Reducing Pump Wear

The fluid entry velocity at the screen face is crucial for downhole equipment and formation stability.

- Reduced Pump Wear: Under the same conditions, the **larger open area** allows groundwater to enter the screen at a velocity **much slower than any other filtering device**. This slow velocity effectively **prevents sand from entering the screen due to high pressure**, thereby greatly reducing **wear and tear** on the impellers, bearings, and seals of **deep well pumps and submersible pumps**, extending their maintenance cycles and service life.

- Extending Well Life: Conversely, groundwater finds it much easier to enter screens with a high open area than those with a low open area. This **slow, stable water flow** not only protects the equipment but also protects the reservoir structure at the well bottom from scouring damage, thereby **extending the well’s lifespan** and stable production period.

- Low Overall Cost: The features of easy backwashing, long service life, safety, and reliability inherent to the trapezoidal wire-welded screen contribute directly to a **low overall integrated cost** when considering operational expenses and maintenance.

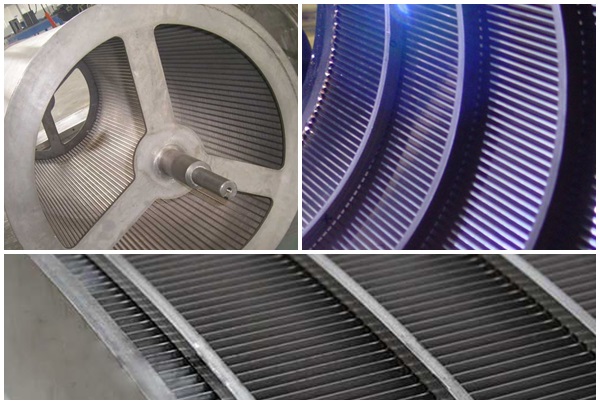

IV. Wide Range of Applications and Multi-Media Filtration

Our wedge wire screens possess characteristics such as **safety, reliability, and low overall cost**, enabling them to handle **multiple media filtration** tasks across the energy, environmental, and water sectors.

| Industry Sector | Core Application and Media Filtration | Product Advantage Highlighted |

|---|---|---|

| Water and Environmental Protection | Deep well water extraction (used with deep well pumps/submersible pumps), tap water treatment, water softening treatment. | High open area reduces energy consumption, extends pump life; precise slots ensure water quality. |

| Seawater Desalination | Pre-filtration before seawater is converted into industrial and domestic water via desalination. | 316/316L material provides excellent resistance to chloride corrosion. |

| Oil and Chemical Industry | Terminal filters for petroleum products, chemical **acid and alkali solution filters**, recovery filters for organic solutions like ethanol. | Heat and corrosion resistance guarantee stability in chemical solutions; precise slots ensure product purity. |

| Energy Extraction | Primary and secondary sand control operations for oil and gas wells. | Robust structure and anti-deformation capability ensure safety and reliability under deep well geological pressure. |

V. Summary: Efficient Filtration, Long-Term Assurance

Our **Wedge Wire Well Screens** provide a filtration solution that surpasses traditional products by combining advanced materials (such as **Stainless Steel 304, 316L**) with innovative engineering design (**V-shaped continuous slot** and **all-welded structure**).

We are committed to supplying products for your projects that feature a **high open area**, **precise slot dimensions**, excellent **mechanical properties**, and an exceptionally **long service life**. Choosing our wedge wire screens is choosing a subsurface cornerstone that effectively controls sand, significantly reduces pump wear, conserves energy, and guarantees safe and reliable long-term production.