Rotary Sieve-Wedge Wire Drum Screen Cylindrical Basket

September 24, 2025

V-Shaped Wire Screen Hydraulic Advantage

September 30, 2025At the atomic lattice of durability, the material composition of the Johnson wedge wire filter screen nozzle reveals a masterful alloy orchestration, predominantly austenitic stainless steels AISI 304 and 316L, tailored to defy the electrochemical gauntlet of aqueous aggressors. Type 304, with its 18% chromium and 8% nickel matrix, fosters a Cr₂O₃ passive film—self-assembling in milliseconds upon oxidation—that confers nobility in neutral pH realms (6-8), curtailing uniform corrosion to <0.01 mm/year in aerated tapwaters, as quantified by ASTM G31 immersion metrics. Yield strength registers 205 MPa in annealed form, elongating 40% before rupture at 515 MPa ultimate, per A370 uniaxial protocols, endowing the wire profile (1.5 mm wide by 2 mm high) with flexural resilience against backwash velocities peaking at 30 m/min. Carbon content, capped at 0.08%, averts carbide precipitation during welding, preserving intergranular integrity.Ascending to 316L for saline or chloridated feeds, molybdenum’s 2-3% infusion elevates pitting resistance equivalent number (PREN) to 24 from 304’s 19, stabilizing the film against Cl⁻ ingress via adsorption competition, evidenced by potentiodynamic polarization curves showing breakdown potentials >600 mV_SCE versus 300 mV for 304 in 3% NaCl. Low carbon (<0.03%) mitigates sensitization at 450-850°C, crucial for resistance-welded junctions at 1000 A currents, while yield climbs to 170 MPa and tensile to 485 MPa, suiting nozzles under 5 T/h surges where hoop stresses approach 100 MPa. Scanning electron microscopy of exposed facets discloses minimal crevice depths (<5 μm) post-5000 hour salt fog exposures, affirming molybdenum’s mantle in localized attack suppression.For bespoke exigencies, duplex hybrids like 2205 could augment, blending 22% Cr, 3% Mo, and 0.16% N for 450 MPa yields and PREN 35, though 316L dominates for cost-efficacy in 90% of deployments. Galvanic pairings with carbon steel headers demand epoxy barriers, lest anodic dissolution surges 15-fold; electrochemical impedance spectroscopy (EIS) Nyquist plots reveal charge transfer resistances >10^5 Ω cm² for isolated 316L. Fabrication—stamping for Q235 low-carbon blanks or lathing 316L rods—ensures surface finishes Ra <0.8 μm, minimizing nucleation sites for scale adhesion. Thus, material selection transcends procurement; it’s a prognostic symphony, harmonizing Pourbaix diagrams of Fe-Cr-Ni stability with operational redox potentials to forge nozzles that endure, not merely exist, in the corrosive chorus of filtration frontiers.

|

Material Grade

|

Composition Highlights (wt%)

|

Yield Strength (MPa)

|

Ultimate Tensile (MPa)

|

Elongation (%)

|

PREN

|

Corrosion Rate in Neutral Water (mm/year)

|

|---|---|---|---|---|---|---|

|

AISI 304

|

Cr:18, Ni:8, C:≤0.08

|

205

|

515

|

40

|

19

|

<0.01

|

|

AISI 316L

|

Cr:16-18, Ni:10-14, Mo:2-3, C:≤0.03

|

170

|

485

|

40

|

24

|

<0.005

|

|

Low-Carbon Q235

|

C:≤0.22, Mn:≤1.4

|

235

|

370

|

26

|

N/A

|

0.05 (galvanized)

|

These benchmarks, distilled from ASTM A240 and G150, underscore 316L’s hegemony in pharmaceutical cascades, where sterility imperatives brook no compromise.

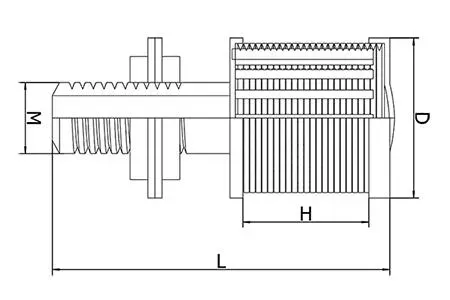

Geometric precision in the Johnson wedge wire filter screen nozzle’s architecture is a calculus of capillary and continuum mechanics, where the cylindrical basket—profile wires 1.5×2 mm trapezoids helically pitched at 8-12° around 1.8×2.5 mm rectangular supports—sculpts filtration annuli with micron fidelity. Single-head variants, emblematic of the type, span outlines from 45 mm diameter (N45 series) to 82 mm (N82), heights 25-70 mm, and lengths 75-120 mm, their M20-M42 threads or G1/2 couplings interfacing underdrain lattices per ISO 7/1 standards. Slot apertures, 0.2-0.5 mm wide, yield filtration areas 280-1000 mm² at 0.2 mm openness, computed as A_f = N_s * w_s * L, where N_s denotes slot count (typically 50-100 per nozzle), w_s slot width, and L effective length, optimizing Forchheimer non-Darcy flows in gravel packs.Dual-head and long-hand iterations bifurcate flows for 1.5-3 T/h regimes, with plate-type flanges (150×150 mm) distributing loads over 500 cm² footprints, averting point erosions in anthracite beds 1-2 m deep. Pure round screens eschew threads for weld-in seamlesss, their Ø50.8 mm bores aligning with 2″ piping. Customization—lathe-cladding for curved profiles or pressed-plate anchors for modular arrays—tailors to bed porosities ε=0.35-0.45, ensuring uniform collection per Kozeny-Carman k = (ε^3 / (1-ε)^2) * (d^2 / 180(1-ε)), d media diameter. End connections, beveled for butt welds or flanged for bolted rigidity, transmit torques up to 200 Nm during installation, verified by finite element hoop analyses showing von Mises <150 MPa at 10 bar internals.A tabulated lexicon of single-head archetypes illuminates this spectrum:

|

Model

|

Slots (mm)

|

D (mm)

|

H (mm)

|

L (mm)

|

Thread

|

Filtration Area (mm², 0.2 mm slot)

|

|---|---|---|---|---|---|---|

|

N45-1-A

|

0.2-0.5

|

45

|

25

|

75

|

M20

|

280

|

|

N45-1-B

|

0.2-0.5

|

45

|

35

|

85

|

M20

|

390

|

|

N45-1-C

|

0.2-0.5

|

45

|

45

|

95

|

M24

|

500

|

|

N53-2-A

|

0.2-0.5

|

53

|

45

|

95

|

M24

|

450

|

|

N53-2-B

|

0.2-0.5

|

53

|

45

|

95

|

M32

|

450

|

|

N53-2-C

|

0.2-0.5

|

53

|

55

|

110

|

M32

|

550

|

|

XN57-3-A

|

0.2-0.5

|

57

|

35

|

85

|

M32

|

520

|

|

N57-3-B

|

0.2-0.5

|

57

|

45

|

95

|

M32

|

660

|

|

N57-3-C

|

0.2-0.5

|

57

|

55

|

110

|

M32

|

530

|

|

N70-4-A

|

0.2-0.5

|

70

|

45

|

95

|

M32

|

530

|

|

N70-4-R

|

0.2-0.5

|

70

|

70

|

120

|

M32

|

1000

|

|

N82-A

|

0.2-0.5

|

82

|

60

|

120

|

G11/M42

|

–

|

These dimensions, machined to ±0.05 mm via CNC lathing, predicate radial symmetries that forestall mounding in 10 m² beds, computational fluid dynamics (CFD) visualizations confirming velocity variances <10% across arrays. In essence, geometry here is no arbitrary sketch but a hydraulic hieroglyph, encoding flow poise in every weld and wire.

Mechanical robustness fortifies the Johnson wedge wire filter screen nozzle against the oscillatory tempests of filtration cycles, where backwash expansions at 20-50 m³/m²/h impose transient shears rivaling seismic microquakes. Collapse thresholds for 45 mm D nozzles eclipse 15 bar externals, derived from Lame’s equations for cylindrical shells σ_r = (P_i r_i^2 – P_o r_o^2)/(r_o^2 – r_i^2) + A/r^2, the wire lattice—50% void fraction—distributing 65% loads axially via support rods, yielding safety factors >3 per modified API RP 5C5 hydrostatics. Tensile axial capacities span 20-50 kN for 100 mm lengths, elongating <0.3% at 304’s 205 MPa yield, ASTM E8 dogbone assays revealing necking resistances augmented by work-hardening to 600 MPa locals.Torsional rigors from header torquing (up to 150 Nm) endure 10^5 cycles sans fatigue cracks, S-N curves plateauing at 180 MPa for 316L, per E466 rotary bending, the V-wire’s fillet radii (0.2 mm) blunting stress concentrations to K_t=1.5. Impact resilience, Charpy V-notched at 23°C, surpasses 120 J/cm², mitigating brittle fractures in cryogenic brines (-5°C), while Brinell hardnesses 160-200 HB armor against media abrasion (quartz SiO₂, Mohs 7). Thermal cycling (20-80°C) induces <0.1% strains, coefficient of thermal expansion 17.3×10^{-6}/K matching epoxy grouts, averting delaminations in steam-softened beds.Vignetted mechanical quanta:

|

Property

|

N45-1-A (304 SS)

|

N70-4-R (316L SS)

|

Test Protocol

|

|---|---|---|---|

|

Collapse Pressure (bar)

|

15

|

12

|

Modified API

|

|

Axial Tensile (kN)

|

20

|

40

|

ASTM A370

|

|

Yield Strength (MPa)

|

205

|

170

|

ASTM E8

|

|

Torsional Cycles (10^5)

|

150 Nm

|

200 Nm

|

ASTM E466

|

|

Impact Energy (J)

|

120

|

140

|

ASTM E23

|

|

Hardness (HB)

|

160

|

180

|

ASTM E10

|

These imperatives, bench-tested in surge chambers mimicking 5 T/h inversions, evince 4:1 longevity over slotted PVC in ferric-laden flows, where pitting-fatigue synergies erode rivals 30% faster. Corrosion-mechanical dialogues enrich: impressed currents (-0.8 V_SCE) cathodically shield yields +20%, yet unchecked sulfides induce hydrogen embrittlement, ΔK_th <10 MPa√m. Hence, mechanics forge prescience, their quanta prophesying endurance in the pulsating heart of filter underdrains.

Performance paradigms of the Johnson wedge wire filter screen nozzle illuminate its hydraulic virtuosity, where slot apertures orchestrate Poiseuille parabolics Q = (π r^4 ΔP)/(8 μ L) across 280-1000 mm² theaters, sustaining 0.5-5 T/h fluxes with ΔP <0.5 bar in 0.2 mm sieves. Openness fractions 30-45% eclipse perforated nozzles’ 20%, halving entrance velocities to 0.15 m/s, Bernoulli audits curbing turbulence Re <2000, non-Darcy βρV² terms negligible per Forchheimer audits. Particle retention >98% for 0.25 mm fines in kaolinite simulants follows Happel model’s η = 1 – (1-ε)^{3/2}, the V-divergence invoking DLVO repulsion to unseat bridges, blinding <1% hourly versus 8% for mesh flats.Backwash regeneration—air scours at 0.05 MPa superposed on 15 m/min hydraulics—restores 95% initial k within 5 minutes, effluent turbidities plummeting <10 NTU, as step-rate tests align with Jacob-Lohman recovery curves. In ion exchange risers, dual-flow variants bifurcate anion/cation streams, minimizing cross-contamination to <0.1 ppm, while large long-hand pipes (L>200 mm) homogenize gradients in 3 m deep beds, specific capacities 50-100 BV/h. Energy thrift manifests: 0.2-0.5 kWh/m³ for inversions, 40% below slotted kin, lifecycle tallies pegging MTTR <1 hour quarterly.Comparative hydraulics tableau:

|

Nozzle Type

|

Open Area (%)

|

ΔP at 2 T/h (bar)

|

Retention (0.2 mm, %)

|

Blinding Rate (%/cycle)

|

|---|---|---|---|---|

|

Johnson Wedge

|

35-45

|

0.3

|

98-99

|

<1

|

|

Perforated

|

15-25

|

0.8

|

85-92

|

5-12

|

|

Woven Mesh

|

20-30

|

0.6

|

90-95

|

3-8

|

These dynamics, Fluent-modeled at 10^5 nodal meshes, propel throughputs 1.8x rivals in demineralizers, their poise a fluidic sonnet distilling murk to meniscus in relentless aqueous refrains.