Stainless Steel Multi-Layer Cyclic Well Filter Pipe

April 4, 2025

The Profound Influence of Manufacturing Processes on the Microstructure and Performance of Stainless Steel Well Screens

September 6, 2025Gravel Pack Screen for Water Sand-Control – Scientific and Technical Analysis

1. Introduction to Gravel Pack Screen Technology

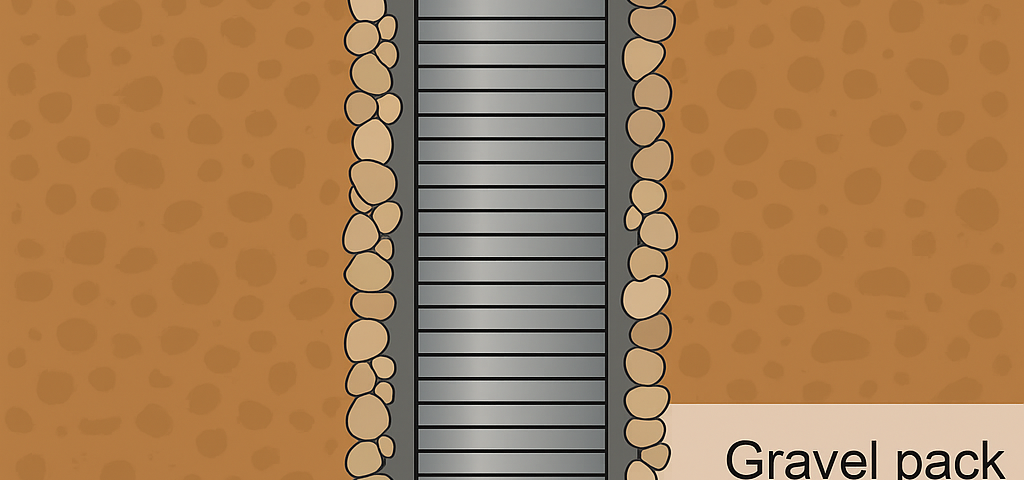

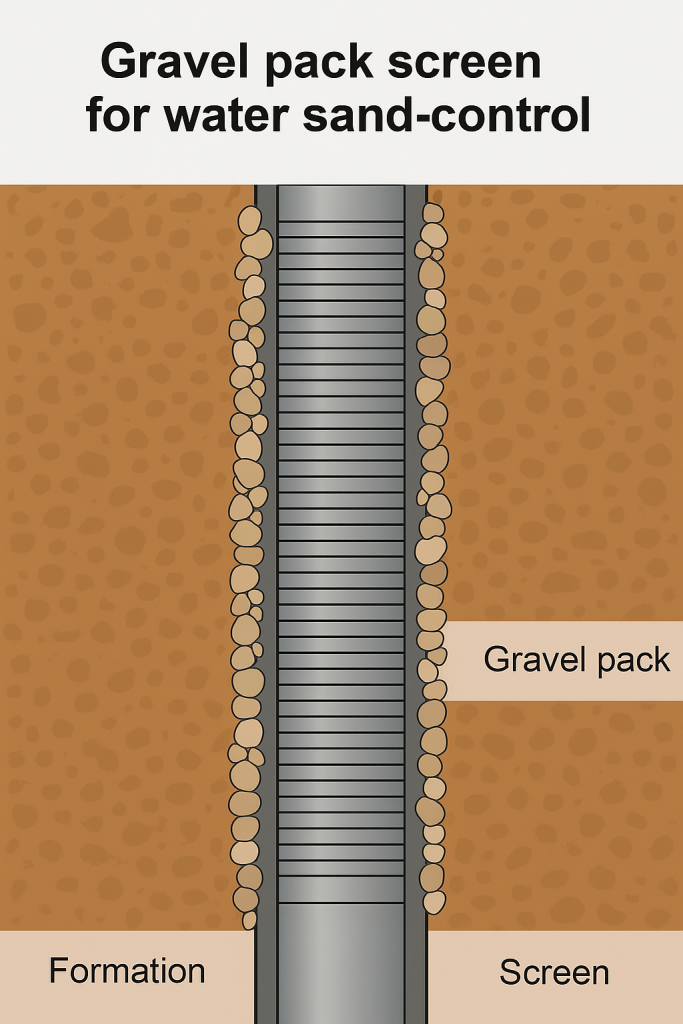

Gravel pack screens represent a critical technology in sand-control systems for water wells, oil and gas wells, and other subsurface extraction environments where unconsolidated or loosely consolidated formations produce excessive sand during fluid production. Sand intrusion into the wellbore can result in severe damage to pumping equipment, blockage of the flow path, reduction in production rates, and increased maintenance costs. Gravel pack screens, when properly designed and installed, provide an effective physical barrier that allows formation fluids (water, oil, or gas) to enter the well while preventing the migration of sand and fine particulates into the production tubing. This is achieved through a combination of a precision-engineered screen assembly and a graded gravel pack that surrounds the screen, forming a filtration zone between the formation and the wellbore.

The principle of operation involves placing a high-permeability gravel layer around the screen, sized to block the formation’s sand particles while allowing produced fluids to flow through with minimal pressure drop. The screen serves as a mechanical support to prevent gravel pack collapse and as a secondary filtration layer. Gravel pack screens can be constructed from a variety of corrosion-resistant alloys and are often designed with specific slot sizes, wire-wrapped configurations, or premium metal-mesh assemblies to match the particle size distribution of the formation sand. The combination of gravel packing and a well-designed screen has been proven to significantly extend the operational life of water wells and production wells, particularly in environments where abrasive particles and high flow rates pose a challenge to conventional completion methods.

Our company specializes in the design, engineering, and manufacturing of gravel pack screens tailored for water well sand-control. With decades of field experience and advanced manufacturing capabilities, we ensure each product meets stringent performance standards for mechanical strength, filtration efficiency, and resistance to corrosion and erosion. In the following sections, we will provide an in-depth technical analysis of our gravel pack screen products, including detailed product descriptions, mechanical properties, specifications, material composition, performance analysis, applications, and quality assurance measures.

![]()

2. Product Description

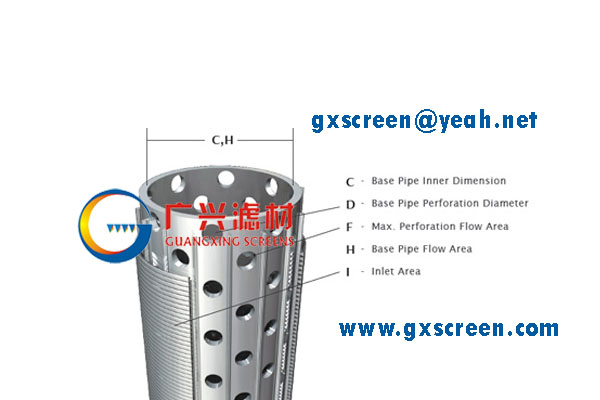

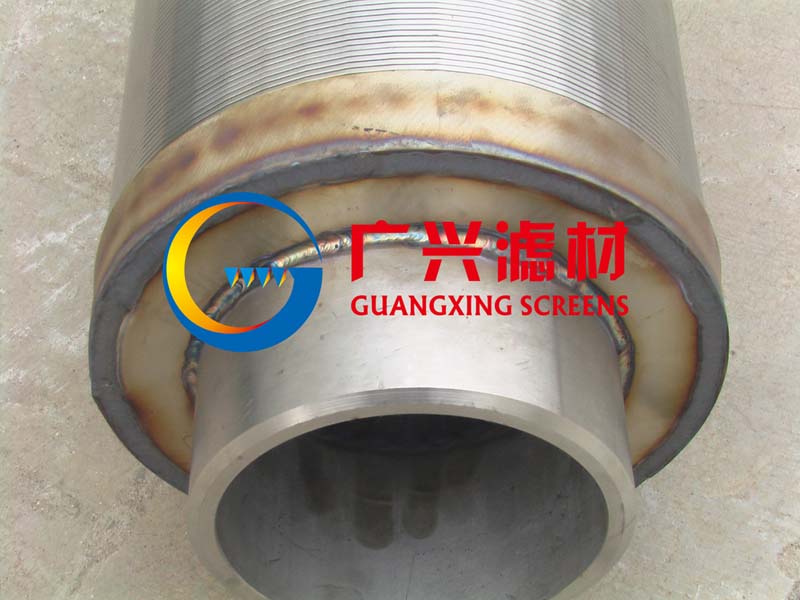

Our gravel pack screen products are precision-engineered filtration devices used in water wells and sand-control applications to ensure maximum fluid productivity while minimizing sand ingress. Each screen consists of a base pipe (often API 5CT standard casing or tubing) with a perforated or slotted design to allow fluid entry, covered by a filter medium (such as wire wrap or metal mesh) that provides precise filtration. The gravel pack is placed in the annular space between the screen and the borehole wall, creating a two-stage filtration system: the gravel layer blocks the majority of formation sand, while the screen captures any residual fines that pass through the gravel.

The gravel pack screens we manufacture are available in a range of configurations, including direct wrap, slip-on, rod-based wire wrap, and premium mesh screens. Each design is selected based on the well’s specific sand-control requirements, fluid properties, and expected production rates. The base pipe material is available in high-strength carbon steels or corrosion-resistant alloys such as stainless steels and nickel-based alloys, depending on the water chemistry and operational environment. Our manufacturing tolerances ensure uniform slot openings, which is critical for maintaining consistent filtration performance across the entire length of the screen.

| Parameter | Specification Range |

|---|---|

| Outer Diameter (OD) | 3 1/2″ to 13 3/8″ |

| Length | Up to 12 meters (custom lengths available) |

| Base Pipe Material | API J55, K55, L80, 316L SS, 904L, Inconel, Hastelloy |

| Filter Type | Wire wrap, Metal mesh, Perforated |

| Slot/Opening Size | 0.15 mm to 3.0 mm |

| Connection Type | API LTC, BTC, Premium connections |

3. Mechanical Properties

The mechanical integrity of a gravel pack screen is crucial to ensure its long-term reliability under the stresses encountered during installation and operation. Our gravel pack screens are designed to withstand axial loads, collapse pressures, and torsional stresses that occur in water well completions. The base pipe is engineered to provide the necessary structural strength, while the filter medium is bonded or welded to resist delamination or separation under differential pressures. We conduct rigorous finite element analysis (FEA) during the design stage to simulate real-world operational conditions, ensuring that each product meets or exceeds industry standards for mechanical performance.

| Property | Typical Value |

|---|---|

| Tensile Strength | ≥ 600 MPa |

| Yield Strength | ≥ 450 MPa |

| Collapse Resistance | As per API 5CT, dependent on size and grade |

| Burst Resistance | ≥ 30 MPa |

| Maximum Operating Temperature | Up to 400°C (depending on alloy) |

| Corrosion Resistance | High, depending on material selection |

4. Common Specifications

Our gravel pack screens are manufactured to comply with internationally recognized standards and specifications to ensure compatibility with well completion systems and to meet the performance demands of our clients. We follow API (American Petroleum Institute) specifications for base pipe, ISO standards for filtration media quality, and customer-specific engineering requirements for special applications. The table below outlines some of the most common specifications our products meet:

| Standard | Description |

|---|---|

| API 5CT | Specification for casing and tubing |

| ISO 17824 | Sand control screen testing standard |

| NACE MR0175 | Material requirements for resistance to sulfide stress cracking |

| ASTM A312/A213 | Specifications for stainless steel pipes |

| ASME B31.3 | Process piping design compliance |

5. Chemistry Nominal Composition

Material selection for gravel pack screens is critical for ensuring both mechanical strength and corrosion resistance. Depending on the operational environment, base pipe and filter media can be manufactured from various alloys. Below is an example of nominal composition for a stainless steel gravel pack screen using 316L stainless steel for the filter medium and base pipe:

| Element | Composition (%) |

|---|---|

| Iron (Fe) | Balance |

| Chromium (Cr) | 16.0 – 18.0 |

| Nickel (Ni) | 10.0 – 14.0 |

| Molybdenum (Mo) | 2.0 – 3.0 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Carbon (C) | ≤ 0.03 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.03 |