: Analyzing the Impact of Well Screen Diameter on Horizontal Gas Well Productivity

December 5, 2025

Why is the V-shaped wire profile superior to traditional bridge slot or perforated pipes for sand control?

December 27, 2025The Ultra-Resilient Dual-Layer Gravel Pack Screen for Horizontal Wellbore Integrity

The evolution of modern hydrocarbon extraction has inexorably shifted towards complex well architectures, with the horizontal wellbore becoming the standard means of maximizing reservoir contact in unconventional and low-permeability plays. While horizontal drilling unlocks vast reserves, it simultaneously magnifies the complexities of downhole completion, particularly concerning sand control. The traditional challenges of fine particle migration, formation instability, and fluid-induced erosion are exacerbated by the sheer length of the open hole, differential flow along the pay zone, and the necessity of high-intensity intervention methods like gravel packing and hydraulic fracturing. Furthermore, in the realm of Enhanced Oil Recovery (EOR), methods such as steam injection (e.g., SAGD) introduce the devastating threats of extreme thermal cycling and high-temperature corrosion.

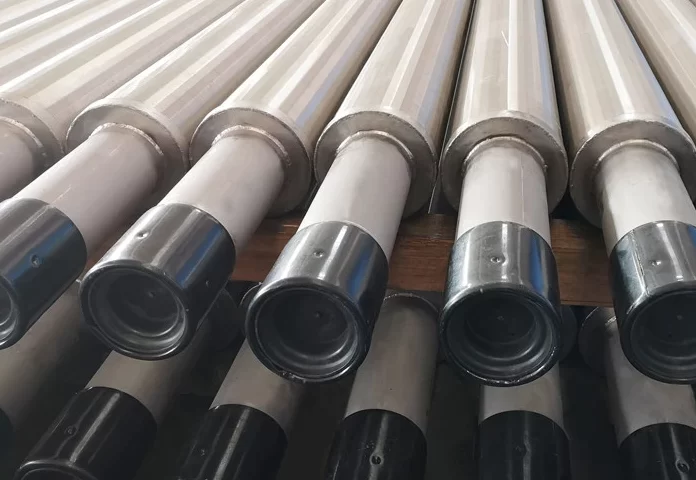

The traditional well screen, whether a simple slotted liner or a standalone wire-wrapped screen, often proves inadequate for these synergistic stresses. This necessity for a component that can withstand high mechanical loads, resist aggressive chemical attack, and maintain precise filtration accuracy over vast horizontal distances has driven the development of the specialized Horizontal Well Gravel Pack Screen. This system represents a significant step forward, utilizing an innovative dual-layer filtration structure—combining a high-strength, erosion-resistant Vee-Wire external jacket with a high-precision fine woven wire mesh internal filter—to ensure not only reliable sand control but also the structural and thermal resilience required for the most rigorous completion and production cycles. The entire system is engineered as a high-integrity asset designed to absorb the immense stresses of gravel placement and fracturing flowback while mitigating the long-term clogging issues posed by mud, heavy oil fines, and mineral scale.

1. The Complexities of Horizontal Well Sand Control and Intervention

The engineering justification for this specialized screen begins with an analysis of the unique operational demands placed upon sand control devices in horizontal wells, particularly those requiring intervention like gravel packing or fracturing.

The Challenge of the Horizontal Wellbore

In a typical horizontal completion spanning thousands of meters, the screen is subject to mechanical stresses rarely encountered in vertical wells. It must maintain its integrity under significant compressive and tensile loading during installation, particularly when navigating tortuous well paths. Once installed, differential drag forces during flow or injection, coupled with massive thermal expansion and contraction cycles inherent to steam injection processes, impose severe fatigue stresses on the screen’s welded structure and connections. Conventional screens often succumb to structural failure at connection points or collapse due to uneven gravel pack placement pressure.

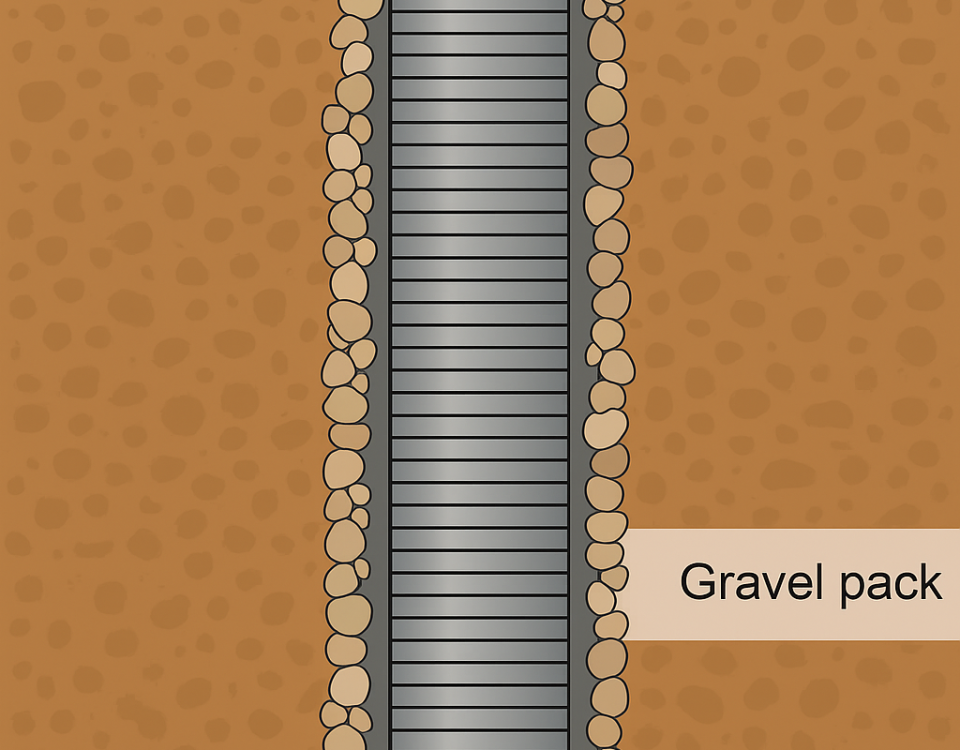

Gravel Packing and Fracturing: The Load Extremes

The screen’s structural requirement is defined by two primary intervention procedures:

-

Gravel Packing: This involves pumping a high-density slurry of sized gravel (proppant) into the annular space between the screen and the formation. The screen must resist immense external squeeze pressure as the slurry fluid leaks off into the formation, requiring a high Collapse Strength in the base pipe and the wire jacket. If the screen collapses even slightly, the integrity of the entire gravel pack is compromised, leading to premature sand production.

-

Hydraulic Fracturing (Frac-Pack): During proppant flowback following a fracturing operation, the screen faces extreme internal erosion. The high-velocity return of the proppant, especially through the slot apertures and near the base pipe perforations, can quickly wear down the screen material. The need for higher erosion resistance dictates the use of specialized, hard-wearing alloys and a robust structural design to minimize localized velocity acceleration.

The requirement to withstand both these high-load operations necessitates a product far superior to a simple perforated liner or a standard single-layer premium screen. The final design must inherently possess the mechanical capacity of high-strength tubing while offering the filtration precision of a specialized filter.

2. The Architecture of Resilience: The Dual-Layer Integrated Structure

The key innovation of this horizontal well screen lies in its layered structure, designed to assign specific mechanical and filtration roles to each component, thereby achieving superior performance in strength, flow capacity, and anti-clogging reliability.

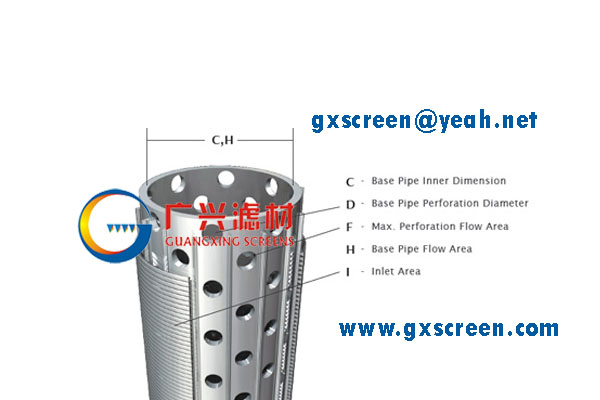

Layer 1: The High-Strength Base Pipe and Perforations

The foundation is the Base Pipe, which is typically API 5CT seamless steel casing or tubing (e.g., 2-7/8″ to 4-1/2″ OD, as per the specified parameters). The base pipe provides the vast majority of the screen’s tensile strength and collapse resistance, crucial for handling, installation, and resisting the external pressures of the gravel pack. The base pipe is perforated with precision-machined holes that must:

-

Maximize Inflow Area (OFA): Ensure maximum fluid entry into the pipe.

-

Maintain Strength: The perforation pattern must be optimized to achieve the maximum OFA while retaining the required minimum collapse strength of the base material (e.g., 80% of the original pipe body collapse resistance).

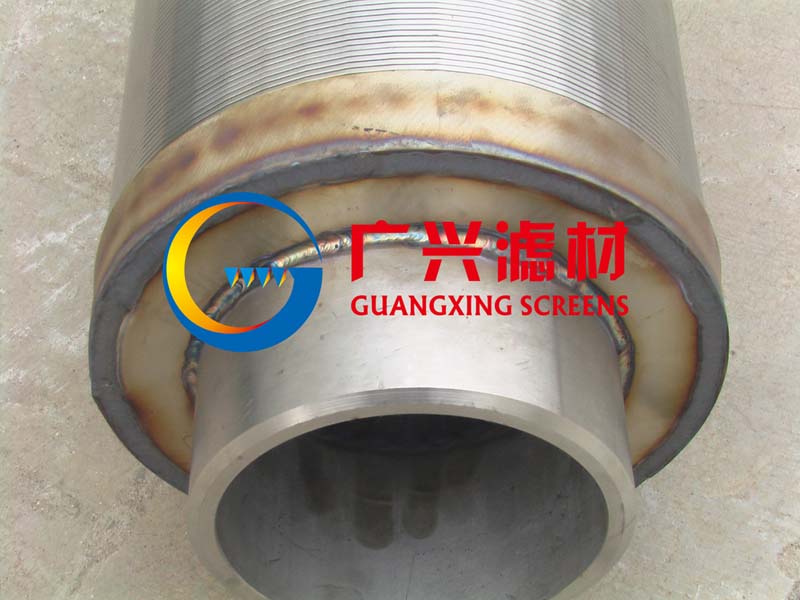

Layer 2: The Fine Woven Wire Mesh (High-Precision Filtration)

Directly enveloping the perforated base pipe is the Inner Filter Layer, typically a sintered multi-layer woven wire mesh (密纹网). This is the high-precision filtration component whose role is two-fold:

-

Final Particle Exclusion: It is designed to trap the finest particles (silt, clay, mud solids, or fine sand) that successfully pass through the coarser primary gravel pack material. This prevents the migration of these fines into the base pipe perforations, thereby minimizing pressure drop (skin damage) and the risk of eventual erosion failure of the pipe itself.

-

Heavy Oil/Mud Mitigation: In heavy oil reservoirs, high-viscosity crude or drilling fluid residue can physically ‘blind’ the filter medium. The inner fine mesh, backed by the robust outer layer, allows the high-viscosity fluid to pass through a large, supported surface area, reducing the risk of differential pressure across the medium that could cause permanent clogging (or blinding) of the filter.

Sintered mesh is preferred over simple woven mesh because the sintering process (fusing the layers of mesh together at high temperature) creates an extremely stable, high-strength filter medium with a uniform, guaranteed pore size, making it highly resistant to mechanical deformation during high-pressure fluid passage.

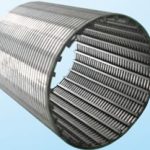

Layer 3: The Vee-Wire Jacket (Structural and Flow Support)

The outermost and most visible layer is the Vee-Wire (Wedge-Wire) Jacket. This component serves as the structural backbone of the filter jacket and the primary erosion shield.

-

Structural Integrity: The precision-welded continuous V-wire, wrapped around longitudinal support rods, creates a rigid cylindrical jacket. This layer resists mechanical damage during handling and provides the necessary strength to support the inner fine mesh against the immense differential pressure and physical abrasion of the gravel pack slurry.

-

Anti-Clogging Flow: The V-shaped wire profile creates an outward-tapering slot aperture. Any particle that passes the primary gravel pack and the outer surface of the V-wire cannot become wedged within the slot—it must pass entirely through. This geometry fundamentally eliminates internal particle bridging, maintaining the inflow efficiency.

-

Erosion Shield: Made from high-hardness, corrosion-resistant alloys, the external V-wire shields the delicate inner mesh from direct contact with the high-velocity, abrasive fluid flow encountered during flowback, particularly after fracturing.

This multi-layer assembly—Base Pipe for load-bearing, Inner Mesh for precision, and Outer Vee-Wire for protection and support—creates an ultra-resilient filtration system optimized for the synergistic stresses of horizontal well completions.

3. Metallurgical Mandates for EOR and Fracturing Environments

The materials used in the construction of the Horizontal Well Gravel Pack Screen must be selected not only for their mechanical strength but also for their resistance to the severe thermochemical environment introduced by EOR and the high erosion rates of fracturing. Standard carbon steel is insufficient for the wire and mesh layers, and even the base pipe requires specific consideration.

Base Pipe Metallurgy: Strength and Flexibility

The base pipe is typically high-strength API 5CT tubing, ranging from J55 (basic strength) up through L80 (NACE sour service qualified, often $80 \text{ ksi}$ yield strength) or P110 (premium high-strength, $110 \text{ ksi}$ yield strength).

-

L80 (NACE Compliance): Mandatory when $\text{H}_2\text{S}$ is present (sour service). The material’s hardness and chemical composition must comply with NACE MR0175/ISO 15156 to prevent Sulfide Stress Corrosion Cracking (SSCC), a failure mechanism accelerated by the high temperatures of steam injection and the tensile stresses in the long horizontal section.

-

P110: Chosen for applications requiring maximum burst and collapse strength to withstand aggressive hydraulic fracturing and high-pressure gravel placement operations.

Filter Jacket and Mesh Metallurgy: Thermal and Chemical Resistance

The Vee-Wire jacket and the inner fine mesh, being the direct fluid interface, require superior alloy content to survive the combined threats of thermal cycling and erosion/corrosion:

-

Chrome Steel (e.g., 13Cr, L80 13Cr): Often the minimum requirement for $\text{CO}_2$ corrosion and moderate temperatures. The $13\%$ Chromium content forms a protective oxide layer, making it significantly more resistant to sweet corrosion than conventional carbon steel. This is frequently used for the V-wire and support rods.

-

Duplex Stainless Steel (e.g., UNS S31803 or S32750): Mandatory for higher temperatures and environments with combined $\text{H}_2\text{S}$ and high chlorides. Duplex alloys offer excellent Pitting Resistance Equivalent Number (PREN) (typically $\text{PREN} \geq 32$) and are highly resistant to stress corrosion cracking, making them ideal for the severe thermal cycling and corrosive environment of steam injection (SAGD/CSS) where high thermal stress is unavoidable.

-

Sintered Mesh: The inner mesh often utilizes alloys like Stainless Steel 316L for corrosion resistance and thermal stability, sintered for enhanced mechanical strength and pore stability under high differential pressure.

The high-strength base pipe combined with the corrosion-resistant alloy jacket ensures that the system maintains structural integrity while the functional components resist chemical and physical degradation.

| Parameter | Base Pipe (API 5CT L80/P110) | Filter Jacket (13Cr / Duplex) | Heat Treatment Requirements |

| Material Grade | API 5CT L80 or P110 | 13Cr (AISI 420 Mod) or Duplex (2205) | Base Pipe: Quenching & Tempering (Q&T) for specified strength and hardness control. |

| Chemical Focus | Controlled Carbon, Mn (for strength) | High $\text{Cr}$ (13% to 25%), $\text{Mo}$ (Duplex), $\text{Ni}$ | Jacket: Solution Annealing after welding (for Duplex) to restore ideal microstructure. |

| Tensile Strength | L80: $552 \text{ MPa}$ min, $P110: 758 \text{ MPa}$ min | Typically $R_{eH} \geq 550 \text{ MPa}$ (Comparable to base pipe) | Annealing for mesh to ensure ductility and prevent intergranular corrosion. |

| Harness Control | Mandatory NACE MR0175/ISO 15156 limits (for L80) | Controlled to prevent SSC (Sulfide Stress Cracking) | N/A |

| Key Standard | API Spec 5CT | ASTM A790/A240 (for Duplex) or Specific Vendor Specification | API 5CT / NACE MR0175 |

4. Dimensional Specification, Tolerances, and Application

The dimensional parameters of the Horizontal Well Gravel Pack Screen are constrained by the need to fit within standard casing sizes while leaving sufficient annulus for the gravel pack slurry and maintaining minimal OD variation for smooth running.

Dimensional Parameters and Fit-for-Purpose Design

The relationship between the Base Pipe OD and the final Screen Jacket OD is critical for ensuring proper clearance. The provided parameters illustrate the coupling of standard API tubing/casing sizes to a custom screen assembly diameter:

| Base Pipe Size (API Tubing/Casing) | Base Pipe OD (mm) | Final Screen Jacket OD (mm) | Application Context |

| 2-3/8″ | $\Phi 60.3$ | $\Phi 79$ | Small diameter completions, often through-tubing or dual completions. |

| 2-7/8″ | $\Phi 73$ | $\Phi 95$ | Standard coiled tubing or smaller conventional completions. |

| 3-1/2″ | $\Phi 88.9$ | $\Phi 110$ | Common tubing size, allowing sufficient annulus for effective gravel pack. |

| 4″ | $\Phi 101.6$ | $\Phi 121$ | Production casing or larger ID completions. |

| 4-1/2″ | $\Phi 114.3$ | $\Phi 135$ | Large diameter production casing; maximizes flow rate. |

The tight tolerance on the Screen Jacket Outer Diameter (OD) is crucial. It must be uniform across the entire length of the section to ensure proper clearance during installation and to prevent hang-ups. More importantly, the Slot Width Tolerance in the outer Vee-Wire and the Pore Size Tolerance in the inner mesh must be extremely tight (e.g., $\pm 0.05 \text{ mm}$), as this directly impacts the sand control efficiency and the long-term flow capacity.

Features and Anti-Clogging Efficacy

| Feature Category | Descriptive Feature | Functional Advantage in Horizontal/EOR Wells |

| Structural Reliability | High-Strength API 5CT Base Pipe | Withstands high external pressure during gravel pack and high internal tensile/compressive loads. |

| Filtration Precision | Sintered Fine Mesh Inner Layer | High-precision particle exclusion of fines, mud, and heavy oil solids; prevents internal pipe plugging. |

| Anti-Clogging Flow | Vee-Wire External Jacket (V-Shape Slot) | Eliminates particle bridging; minimizes skin damage and maintains flow capacity over time. |

| Erosion Resistance | 13Cr/Duplex Vee-Wire and Rods | Resists wear from high-velocity flowback, particularly proppant return after fracturing. |

| Corrosion Resistance | NACE/Duplex Qualified Alloys | Withstands high temperature, sour service ($\text{H}_2\text{S}/\text{CO}_2$), and chloride stress corrosion cracking (SCC) from steam. |

| Operational Versatility | High Flow Capacity | Suitable for high-rate production, gravel packing, and hydraulic fracturing operations. |

Applications and Market Niche

This specialized screen fills the crucial niche where high mechanical stress meets corrosive EOR environments:

-

Steam-Assisted Gravity Drainage (SAGD) and CSS: Essential for high-temperature heavy oil extraction, requiring resistance to $\sim 300^{\circ}\text{C}$ steam and massive thermal cycling.

-

Unconventional Gas/Oil Fracturing: Used in long horizontal laterals where the screen must survive the erosive forces of fracturing flowback while maintaining precise sand control.

-

High-Deviation Deep Wells: Deployed where the long screen length subjects the component to extreme friction and mechanical stress during installation.

A Commitment to Unconventional Reliability

The Horizontal Well Gravel Pack Screen, with its ultra-resilient dual-layer construction, represents the zenith of contemporary sand control engineering. It is a calculated response to the synergistic mechanical, thermal, and chemical threats inherent in modern horizontal EOR and fracturing completions. The robust structural spine of the API 5CT base pipe is strategically paired with a high-performance filtration medium—the protective Vee-Wire jacket and the precision sintered mesh—made from alloys specifically chosen for their resistance to high-temperature corrosion and erosion.

This system is a testament to the principle that in complex downhole environments, reliability must be manufactured into the component itself. By achieving higher structural integrity and thermal stability, alongside superior filtration precision and anti-clogging flow characteristics, this screen drastically reduces the operational expenditure associated with workovers, cleaning, and premature well failure. The sophisticated architecture ensures that the enormous capital investment made in a horizontal wellbore is protected by a screen designed to endure the lifetime of the most demanding reservoir assets, thereby sustaining high-rate, sand-free production in the world’s most challenging oil and gas fields.