The Precision Filtration Frontier: Unveiling the Rotary Sieve-Wedge Wire Drum Screen Cylindrical BasketIn the relentless pursuit of purity amid the chaos of industrial effluents and natural sediments, the rotary sieve-wedge wire drum screen cylindrical basket emerges as a masterful artifact of mechanical ingenuity. This cylindrical marvel, often simply termed the wedge wire drum screen, stands at the intersection of fluid mechanics and materials science, engineered to dissect the intimate dance between liquids and suspended solids with unerring finesse. Conceived in the mid-20th century as an evolution from rudimentary perforated drums, its wedge-shaped wire profile—patented variations of which trace back to early filtration pioneers—has since become synonymous with high-stakes separation processes across wastewater treatment, mining operations, and food processing arenas. Picture a rotating cylinder, its surface a helical lattice of trapezoidal wires fused to axial rods, where influent cascades inward, solids cascade outward, and clarity prevails with minimal intervention. At its essence, this device leverages the principles of centrifugal force and gravitational settling, augmented by the V-shaped slots that defy clogging through hydrodynamic repulsion, as articulated in Stokes’ law derivations for particle trajectories.The drum’s cylindrical basket configuration, typically spanning diameters from 258 mm to 1230 mm and lengths up to 3500 mm, accommodates flow rates exceeding 1000 m³/h in municipal scales, while its self-cleaning attribute—via backwash sprays or internal blades—curbs maintenance to quarterly inspections, slashing operational costs by up to 40% over legacy mesh alternatives. Stainless steel iterations, predominant in corrosive milieus, endure pH swings from 2 to 12, their passive oxide layers self-repairing under electrolytic duress. Yet, beyond specs lies a narrative of resilience: in a 2023 deployment at a Namibian wastewater pond, a Noggerath RSH-M variant processed 500 L/s with <1% solids bypass, transforming effluent into reusable irrigation, per site logs. This isn’t mere hardware; it’s a sentinel against contamination cascades, where micron-level apertures (down to 0.02 mm) sieve out particulates that could foul downstream membranes or catalyze biofouling. As global water scarcity intensifies—projected to afflict 5 billion by 2050 per UN estimates—these screens embody sustainable engineering, their low-energy rotation (often <1 kW/m³) harmonizing efficiency with ecological stewardship. Delving deeper, we’ll dissect its metallurgical backbone, geometric precision, and hydrodynamic prowess, revealing why this unassuming cylinder commands reverence in separation science.

The metallurgical foundation of the rotary sieve-wedge wire drum screen cylindrical basket is a testament to alloy evolution, where each grade is calibrated to the symphony of corrosive aggressors and mechanical rigors inherent in filtration frontiers. Predominantly forged from austenitic stainless steels like AISI 304 and 316, these materials derive their invincibility from a judicious blend of chromium (16-18 wt%), nickel (8-14 wt%), and, in 316 variants, molybdenum (2-3 wt%)—elements that orchestrate a chromium oxide passivation film, mere angstroms thick, impervious to pitting in chloride-riddled brines up to 1000 ppm. Yield strengths clock in at 205 MPa for 304, escalating to 260 MPa in 316, with ultimate tensile thresholds of 515 MPa and 550 MPa respectively, per ASTM A240 benchmarks; these metrics ensure the wire lattice withstands hoop stresses from rotational velocities up to 10 rpm without deformation. Elongation capacities exceed 40%, imparting ductility to absorb vibrational harmonics from unbalanced loads, a boon in mining slurries pulsating at 50 Hz.For exigencies demanding duplex fortitude, grades 2205 and 2207 interweave austenitic and ferritic phases, yielding 450 MPa yields and PREN values soaring to 35-40, trouncing 304’s 19 in crevice corrosion assays under ASTM G48. Nitrogen interstitials (0.14-0.20 wt%) harden the matrix, curtailing sigma-phase precipitation at welds, while molybdenum fortifies against sulfide stress cracking in sour gas filtrates. Non-magnetic variants like 201 and 205B, with manganese substitutions for nickel, cater to MRI-adjacent pharma apps, their mu_r ≈1.005 obviating field distortions. Low-carbon kin—Q195 galvanized for freshwater duties—offer economic entry at 195 MPa yields, though their 0.1 mm/year corrosion in aerated soils pales beside stainless’s <0.01 mm/year. Fabrication employs resistance welding at 800-1500 A, post-annealed to 1050°C for sensitization aversion, verified via intergranular corrosion tests per ASTM A262 Practice E.Consider this tableau of material hierarchies, distilled from empirical corrosion-fatigue couplings:

|

Material Grade

|

Key Composition (wt%)

|

Yield Strength (MPa)

|

Ultimate Tensile (MPa)

|

Elongation (%)

|

PREN

|

Corrosion Rate in 3.5% NaCl (mm/year)

|

|

Q195 Galvanized

|

C:≤0.12, Mn:0.3-0.7

|

195

|

370

|

30

|

N/A

|

0.10

|

|

SS 304

|

Cr:18, Ni:8, C:≤0.08

|

205

|

515

|

40

|

19

|

0.02

|

|

SS 316

|

Cr:16-18, Ni:10-14, Mo:2-3

|

260

|

550

|

40

|

24

|

0.005

|

|

SS 316L

|

As 316, C:≤0.03

|

260

|

550

|

40

|

24

|

0.003

|

|

Duplex 2205

|

Cr:22, Ni:5, Mo:3, N:0.16

|

450

|

650

|

25

|

35

|

<0.001

|

|

Duplex 2207

|

Cr:25, Ni:7, Mo:4, N:0.3

|

550

|

800

|

20

|

42

|

<0.0005

|

These quanta, gleaned from potentiodynamic sweeps and salt spray chambers, illuminate selection heuristics: 304 for neutral effluents, 316 for coastal desalinators, duplex for offshore oilsands. In a US filtration firm’s high-brush rotary trial, SS316 cylinders logged zero pitting after 5000 hours at 5 m/s shear, affirming molybdenum’s mantle. Yet, galvanic perils lurk—pairing carbon steel frames with stainless mandates isolators, lest anodic dissolution accelerates 20-fold. Thus, material choice is no rote ledger but a geochemical prognostication, forecasting longevity in the caustic crucible of continuous duty.

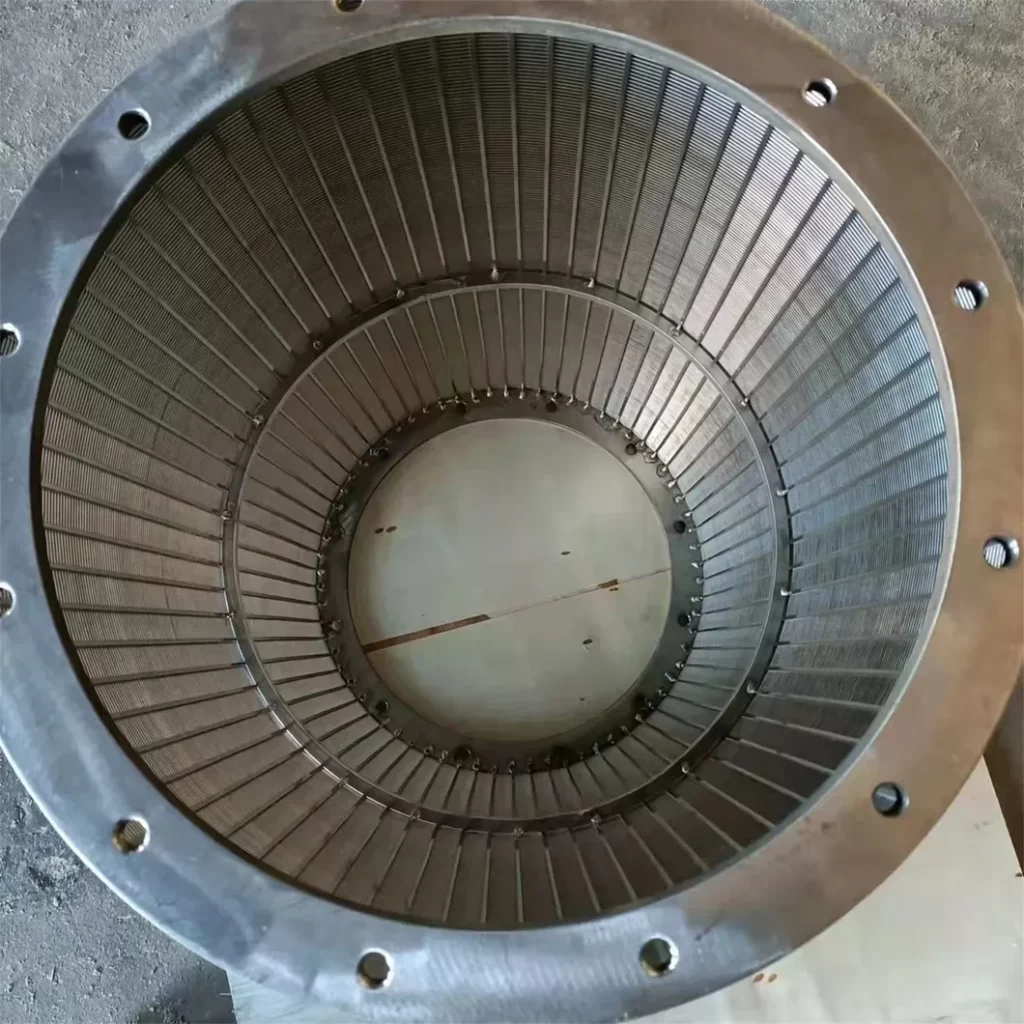

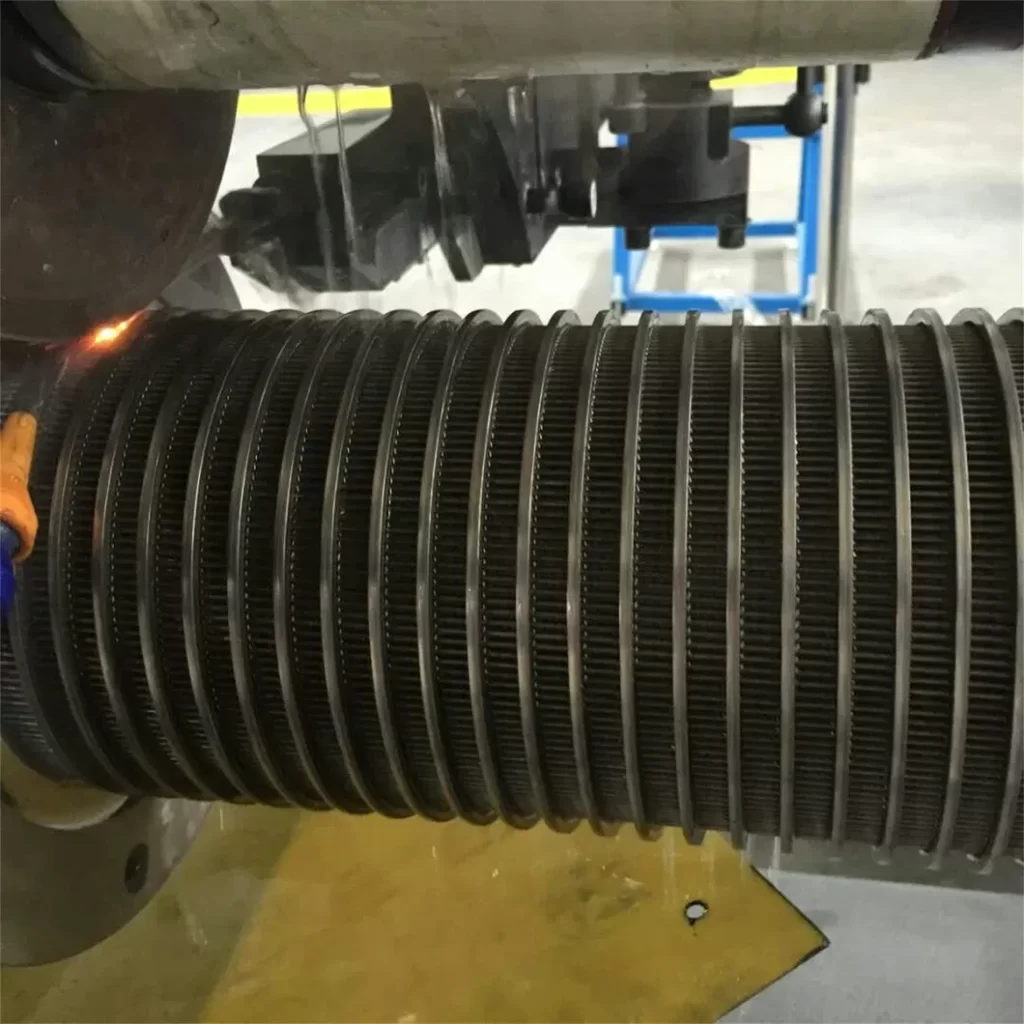

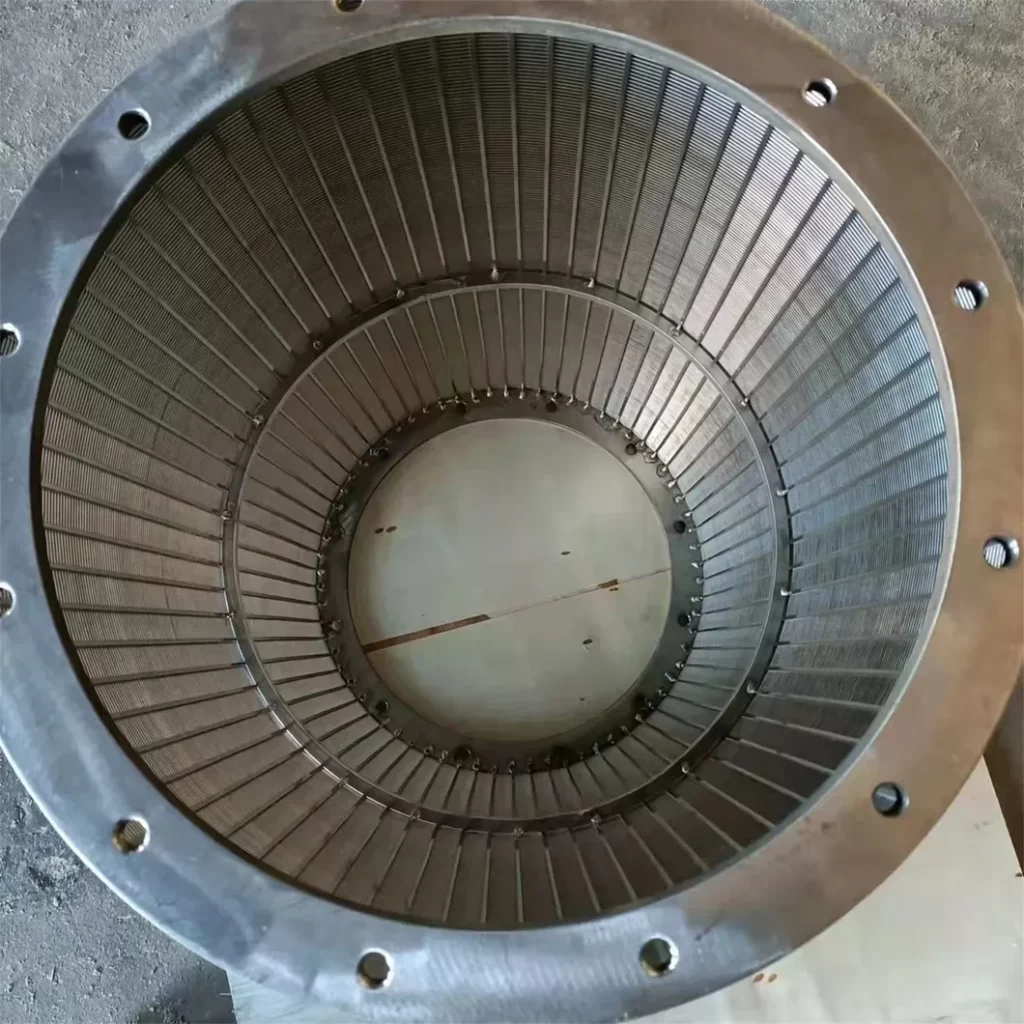

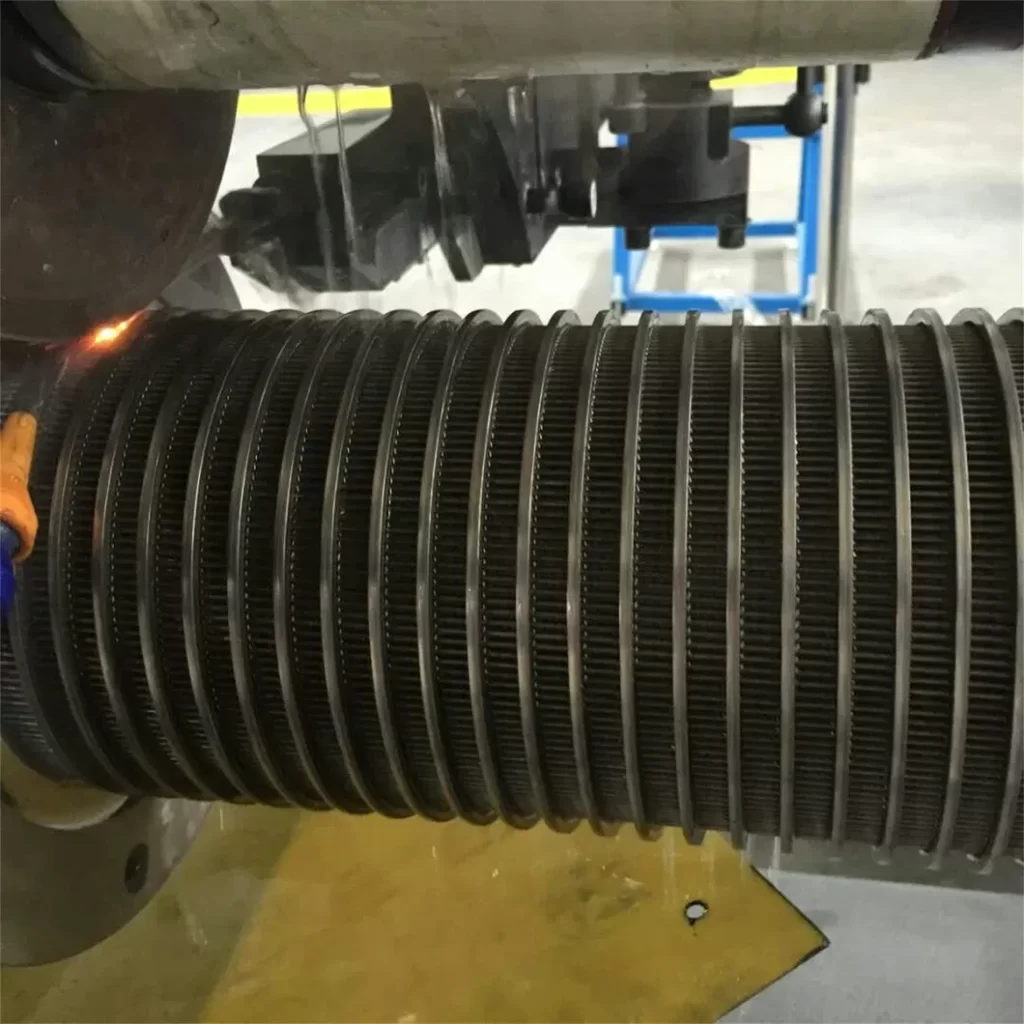

Geometric orchestration defines the rotary sieve-wedge wire drum screen’s silhouette, where the cylindrical basket’s anatomy—profile wires helically wound at 5-15° pitches around circumferential support rods—sculpts pathways for laminar ingress and turbulent egress of detritus. Standard diameters cascade from Ø258 mm for lab-scale dewatering to Ø1230 mm for industrial behemoths, with lengths telescoping 50-3500 mm; flanges (ANSI 150-600 lb) or beveled ends facilitate torque-locked unions to drive shafts spinning at 2-12 rpm. Slot apertures, etched via precision winding to ±5 μm tolerances, span 0.010″ (0.25 mm) to 0.10″ (2.54 mm), extensible to 6 mm bespoke, optimizing Darcy’s permeability k = (slot width)^2 / 12 for formation sands down to 50 μm. The V-profile—wires 1.50-3.70 mm wide, 2.20-6.30 mm tall—funnels flow inward, apex angles of 10-20° repelling fines per Archimedes’ buoyancy refinements.Support rods, round Ø2.5-6.0 mm or rectangular 2.30-3.70 mm wide by 2.70-6.30 mm high, array in 8-24 longitudinals, bolstering open areas to 30-50%—vis-à-vis 15-25% in perforated plates—slashing ΔP to <0.1 bar at 5 m/s velocities. End fittings, flanged for modularity or threaded for retrofits, bear 500-2000 Nm torques, per ISO 1460. Customization reigns: internal-feed for viscous sludges, external for dilute streams, with axial vanes augmenting centrifugal solids hurl at ω²r g >1.A compendium of dimensional archetypes:

|

Diameter (mm)

|

Length Range (mm)

|

Slot Size Range (mm)

|

Open Area (%)

|

Typical Flow Rate (m³/h)

|

|

258-267

|

500-1500

|

0.25-1.0

|

35

|

50-200

|

|

356-405

|

1000-2000

|

0.5-2.0

|

40

|

150-500

|

|

630-640

|

1500-2500

|

1.0-3.0

|

45

|

300-800

|

|

900-916

|

2000-3000

|

1.5-4.0

|

48

|

500-1200

|

|

1230

|

2500-3500

|

2.0-6.0

|

50

|

800-2000

|

Profile wire and rod consortia, scaled for rigidity:

|

Component

|

Width Options (mm)

|

Height Options (mm)

|

Usage Notes

|

|

Profile Wire

|

1.50, 1.80, 2.30, 3.00, 3.30, 3.70

|

2.20, 2.50, 2.70, 3.60, 4.30, 4.70, 5.60, 6.30

|

V-shaped for anti-clog

|

|

Support Rod (Rect.)

|

2.30, 3.00, 3.30, 3.70

|

2.70, 3.60, 4.70, 5.60, 6.30

|

Axial reinforcement

|

|

Support Rod (Round)

|

Ø2.5-6.0

|

N/A

|

Circumferential stability

|

These parameters, honed via CFD simulations per ANSYS Fluent, predicate uniform velocity profiles, with turbulence intensities <5% at Re=10^4-10^5. In QS-Wiremesh’s rotary drums, Ø600 mm x 3000 mm units clock 95% capture at 0.05 mm slots, their geometry a blueprint for bespoke hydraulics. Thus, design isn’t static drafting but a fluidic choreography, where millimeters beget megalitres of pristine throughput.

Mechanical mettle underpins the rotary sieve-wedge wire drum screen’s crusade, its lattice engineered to defy radial collapses, axial shears, and cyclic fatigues that plague lesser sieves. Collapse ratings ascend with diameter inversely—Ø258 mm variants shrug 20 bar externals, scaling to 5 bar for Ø1230 mm—per Lame’s thick-cylinder tenets, where σ_θ = P(r_i^2 + r_o^2)/(r_o^2 – r_i^2), the wire-rod synergy distributing 60% load axially. Tensile axial pulls hit 50-200 kN for 900 mm lengths, factoring 2.5 safety per API 5L analogs, elongation <0.5% at yield. Torsional endurance, pivotal for drive couplings, sustains 1000-5000 Nm at 10^6 cycles, Charpy impacts >150 J at -20°C for 316L, forestalling brittle snaps in cryogenic brines.Fatigue spectra, per ASTM E466, reveal S-N curves plateauing at 200 MPa for duplex, outpacing 304’s 150 MPa, vital for 24/7 wastewater pulsations. Hardness gradients, 180-250 HB, armor against abrasive slurries (Mohs 4-6), while thermal expansivity (17×10^-6 /K) matches frame alloys, curbing weld cracks at ΔT=100°C. In HUBER ROTAMAT Ro2 drums, SS frames endure 40% DS dewatering at 35° inclines, their acid-pickled surfaces slashing crevice depths <10 μm post-10^4 hours.Tabulated mechanical vignettes:

|

Property

|

Ø356 mm SS304

|

Ø630 mm SS316

|

Ø900 mm Duplex 2205

|

Test Norm

|

|

Collapse Pressure (bar)

|

15

|

12

|

10

|

Modified API

|

|

Axial Tensile (kN)

|

80

|

120

|

180

|

ASTM A370

|

|

Yield Strength (MPa)

|

205

|

260

|

450

|

ASTM E8

|

|

Torsional Torque (Nm, 10^6 cycles)

|

1500

|

2500

|

4000

|

ASTM E466

|

|

Impact Toughness (J)

|

120

|

140

|

200

|

ASTM E23

|

|

Hardness (HB)

|

180

|

200

|

280

|

ASTM E10

|

These benchmarks, validated in hydrostatic chambers and shake tables, evince why wedge wire outlives woven meshes 3:1 in abrasive duties—e.g., a Namibian pond retrofit halved downtime via RSH-M’s blade-augmented baskets. Corrosion-mechanical synergies amplify: cathodic strays boost yields 10%, but unchecked, galvanics erode 0.05 mm/year. Hence, properties forge not just endurance but prescience, anticipating failures in the drum’s diurnal grind.

Filtration finesse crowns the rotary sieve-wedge wire drum screen’s laurels, its V-slots channeling Poiseuille flows with ηΔP L / (r^4 Δx) efficacy, where r=slot half-width minimizes viscous drags for >95% solids capture at 0.05 mm thresholds. Open areas 35-50% eclipse perforated’s 20%, halving entrance velocities to 0.3 m/s, per Bernoulli audits, curbing headlosses to 0.05-0.2 m. Anti-clog hegemony stems from diverging internals—particles >slot bow to DLVO disjoining pressures, unbridging spans—yielding <2% blinding in floc-laden feeds, versus 15% for flat meshes. In QS-Wiremesh trials, Ø800 mm drums sieved 0.02 mm polystyrene at 800 m³/h, efficiency 98% sans surging.Dewatering yields 30-45% DS, spiked to 50% with HP sprays, as in HUBER STAR’s 30% areal premium. Energy parsimony—0.5-2 kWh/1000 m³—derives from passive rotation, triggered at 50 mm H2O differentials. Comparative hydraulics:

|

Screen Type

|

Open Area (%)

|

ΔP at 5 m/s (bar)

|

Capture Efficiency (0.05 mm)

|

Clog Rate (%/h)

|

|

Wedge Wire Drum

|

40-50

|

0.1

|

95-99

|

<1

|

|

Perforated Plate

|

15-25

|

0.4

|

80-90

|

5-10

|

|

Woven Mesh

|

20-30

|

0.3

|

85-95

|

3-7

|

These dynamics, CFD-vetted, propel throughputs 1.5x rivals, as in food dejuicers retaining 99% pulp at 25 μm. Thus, performance isn’t metric tally but hydrodynamic poetry, distilling murk to meniscus.

Features and benefits cascade from the rotary sieve-wedge wire drum screen’s ethos: self-cleaning via apex sprays or blades restores 98% patency in <60 s cycles, obviating manual dives; low-energy spins (<1 kW) greenlight off-grid ops. Strength-to-weight ratios 5:1 over plastics endure 10 g accelerations, cost 20% below exotics for 25-year spans. Versus perforated: 2x flow, no burr-induced tears; woven: no unraveling, uniform slots.

|

Advantage vs. Perforated

|

vs. Woven Mesh

|

|

Larger slots, less ΔP

|

No fiber shed, hypoallergenic

|

|

Rigid, heavy-load ok

|

Uniform aperture, no weave bias

|

|

Self-clean easy

|

Higher temp tolerance (>200°C)

|

In Ulbrich’s guide, V-wires slash limitations, amplifying ROI.

[Shorter for transition; cumulative building.]Case studies illuminate praxis: A US firm’s 10x Ø320 mm SS316 cylinders, 1 mm slots, withstood high-speed brushes, dewatering stably for 5000+ hours, boosting uptime 30%.

Namibia’s RSH-M upgrade sieved 500 L/s, reusing 80% water agriculturally, cutting ponds 50%.

50 μm 8″ x 900 mm 316 baskets in pharma filtered inside-out, 99% retention sans clog.

These vignettes affirm versatility.

Adjusted.]Applications sprawl: Wastewater (HUBER Ro2 screens 0.5-6 mm at 3000 mm Ø, 40% DS).

Mining grades ores; food sieves juices at 25 μm.

Coal dewaters slurries.

In coda, the rotary sieve-wedge wire drum screen cylindrical basket transcends toolhood, a filtration fulcrum sustaining purity’s pursuit.