filtre de fil de coin | Tamis Wedge

Juin 25, 2023

Quelle est la différence entre l'écran métallique en coin et l'écran perforé?

Août 22, 2023Un tamis rotatif à tambour est un dispositif de filtration mécanique couramment utilisé dans diverses industries, y compris les sucreries, pour séparer des particules solides à partir de liquides ou d'autres solides. Dans le cadre d'un Moulin à sucre, il est principalement utilisé pour séparer les cristaux de sucre du sirop ou de la mélasse.

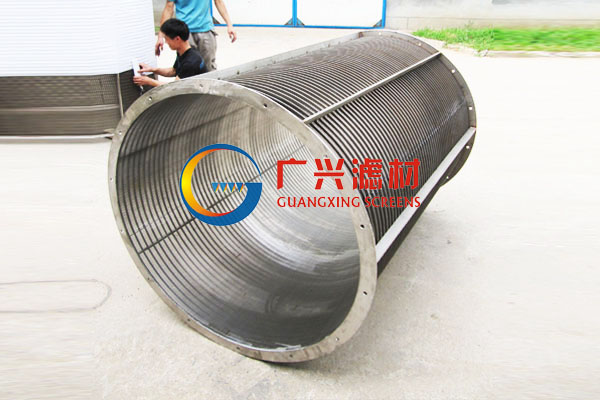

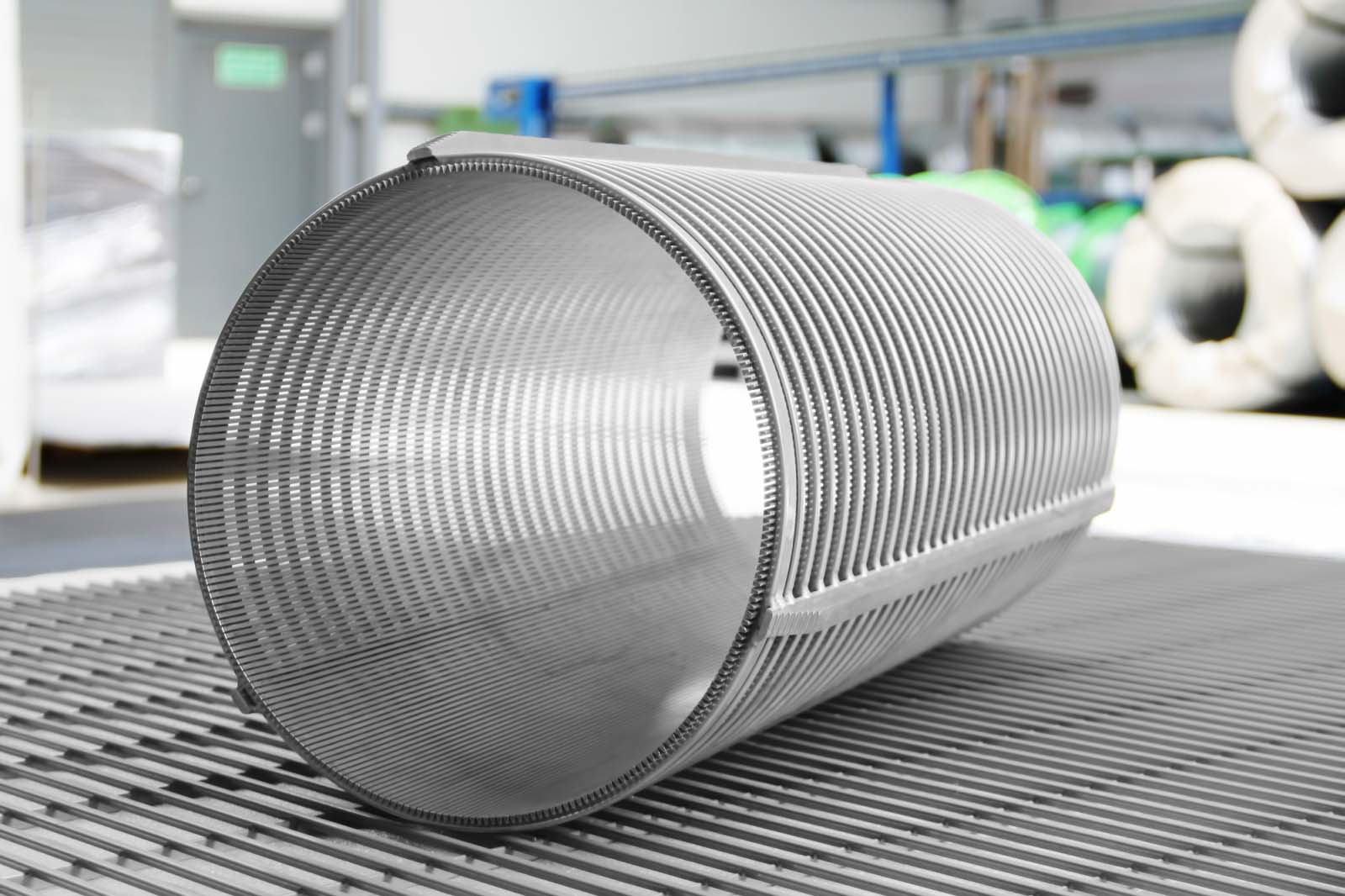

Le tamis rotatif à tambour se compose généralement d'un tambour cylindrique en matériau perforé ou Calez le tamis, qui tourne autour de son axe. Les ouvertures du tamis permettent aux petites particules de passer à travers tout en retenant les plus grosses particules, réalisant ainsi la séparation.

Voici une brève description du fonctionnement du tamis rotatif à tambour dans une sucrerie:

- Nourrir le lisier: La bouillie de sucre, qui est un mélange de cristaux de sucre et de sirop ou de mélasse, est introduit dans le tamis rotatif à tambour. Le lisier peut être alimenté soit par une entrée centrale, soit par un système spécialement conçu système de distribution pour assurer une répartition uniforme sur toute la longueur du tambour.

- Dépistage: Pendant que le tambour tourne, le lisier s'écoule par les ouvertures du tamis. Les cristaux de sucre, étant plus grand que les ouvertures de l’écran, sont retenus à l’intérieur du tambour, pendant que le sirop ou la mélasse, avec des impuretés plus petites, transitent et sont collectés séparément.

- Décharge: Les cristaux de sucre retenus dans le tambour sont finalement évacués d'une extrémité du tambour., généralement via une goulotte ou un système de convoyeur à vis. Les cristaux de sucre déchargés sont ensuite envoyés pour un traitement ultérieur, comme le séchage ou l'emballage.

- Nettoyage: Pour éviter le colmatage et assurer opération efficiente, la tamis rotatif à tambour comprend souvent un système de nettoyage, comme des pinceaux ou Buses de pulvérisation, pour éliminer les cristaux de sucre accumulés ou les impuretés de la surface de l'écran.

Les avantages de l'utilisation d'un tamis rotatif à tambour dans les sucreries comprennent:

- Séparation efficace des cristaux de sucre du sirop ou de la mélasse.

- Opération continue, ce qui entraîne un débit élevé.

- Faibles coûts de maintenance et d’exploitation.

- Conception flexible, permettant une personnalisation facile selon des exigences spécifiques.

En résumé, un tamis rotatif à tambour est un outil précieux outil de séparation dans les sucreries, aider à séparer les cristaux de sucre du sirop ou de la mélasse. Le fonctionnement continu de l’appareil, efficacité, et son faible entretien en font un choix attrayant pour les installations de transformation du sucre.