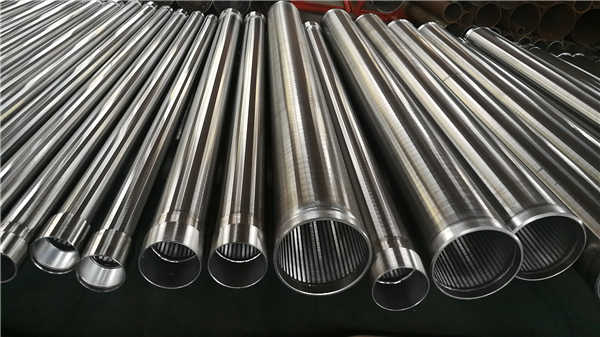

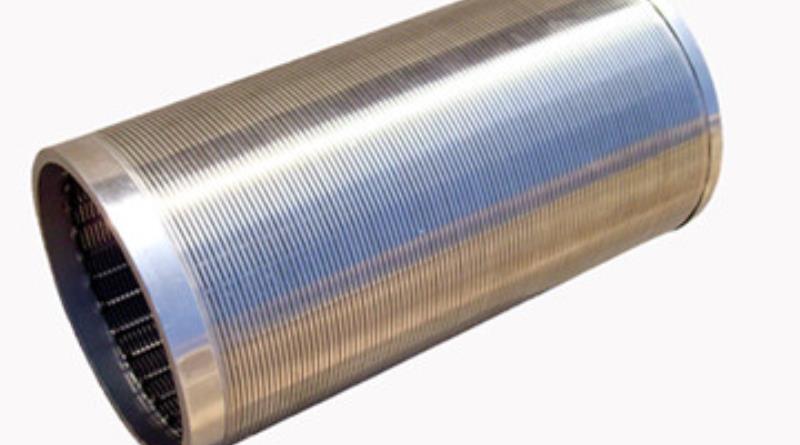

Stainless Steel Johnson wedge wire screen Filter

December 8, 2017

Johnson Wedge Wire Screen Filter Cartridge

December 12, 2017Wedge wire Drum has big advantage than the normal separater screen drum.

Screw presses are used in a wide variety of dewatering applications, often in the same applications as belt presses, centrifuges, and filter presses. The screw press is a simple, slow moving mechanical device. Dewatering is continuous and is accomplished by gravity drainage at the inlet end of the screw and then by reducing the volume as the material being dewatered is conveyed from the inlet to the discharge end of the screw press.

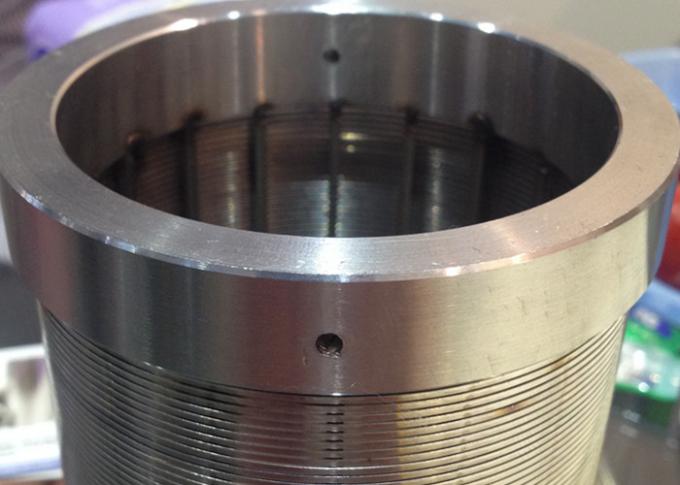

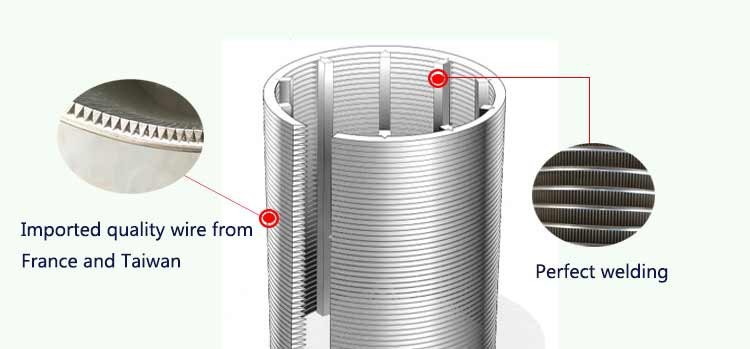

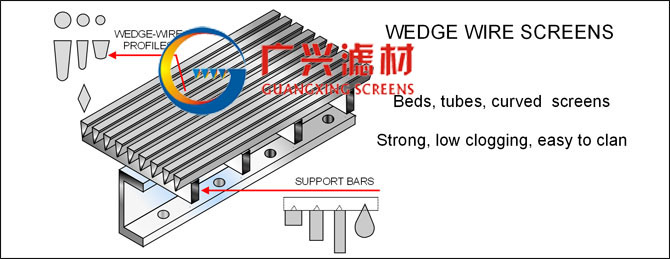

Slotted wedge wire screen is produced through the method of electric resistance welding: wires with special profile are welded to supporting wires at 90 degrees angle. Its characteristic features are accurate production and precise gap sizes, which result in the ability to carry heavy loads. The slotted screen is also characterized by low possibility of blanking, perfectly smooth surface and high open surface ratio. As a result of modern technology of welding, different wires may be used, various slots in one wedge wire screen, as well as different distances between supporting wires can be created.

Screw presses are used in a wide variety of dewatering applications, often in the same applications as belt presses, centrifuges, and filter presses. The screw press is a simple, slow moving mechanical device. Dewatering is continuous and is accomplished by gravity drainage at the inlet end of the screw and then by reducing the volume as the material being dewatered is conveyed from the inlet to the discharge end of the screw press.

Screw press separators are a state of the art technology for the separation of slurry and digester solids. Dewatered digester solids and resulting particle free liquids form an agricultural product that can be handled far easier and utilized for multiple purposes – bedding, flush water

| Material | SS304, SS304L, SS316, SS316L, SS321, Duplex, Hastelloy, etc | ||||||

| OD Range | Min 68mm, the biggest according to clients’ request | ||||||

| ID Range | MIN 60mm, the biggest according to clients’ request | ||||||

| Length Range | Up to 6000 mm | ||||||

| Slot Direction | Radial Direction, Axial Direction | ||||||

| Slot Range | 20 micron to 3000 micron (Tolerance:+-5 micron) | ||||||

| Wedge Wire | 0.5×1.5 | 0.75×1.5 | 1×2 | 1.5*2 | 2×3 | 2*4 | 3*5 |

| Support Rod | 1.5×2.5

2×3 |

1.5×2.5

2×3 |

1.5×2.5

2×3 |

1.8*2.5

2×3 |

2×3

2×4 3×5 3×6 3×10 4×7 |

2×4

3×5 3×6 3×10 4×7 5×6 |

3×5

3×6 3×10 4×7 5×6 5×8 |

| End Finishing | Thread fitting, Flange, Closed Plated, Resistance welded closed plate, Metal Ring, etc | ||||||

| Note | Customized According To Requirement | ||||||

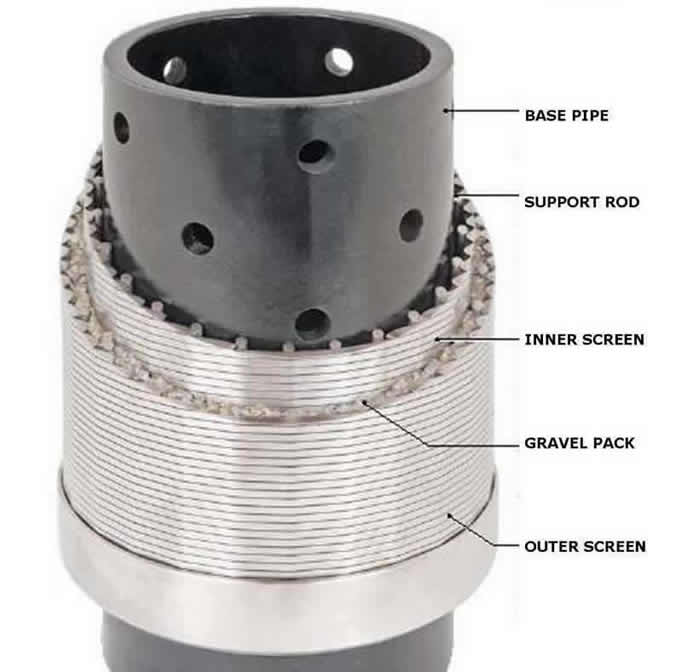

Wedge wire screen is made with profile wire, woven or welded and support rods. Accordingly, it can divided into two major types: woven wedge wire and welded wedge wire.

Dimensions:

– maximum profile wire length of 2000 mm, 2800mm

– maximum support rod length of 4000 mm, 4500mm

– standard spacing between the support rods of: 25, 50, 75,100 up to 300mm and more.

Slot opening can be very micron to 0,03 mm.

used for liquid, gas and solid separation, sizing, dewatering and sifting in oil wells, water wells and the chemical industry.