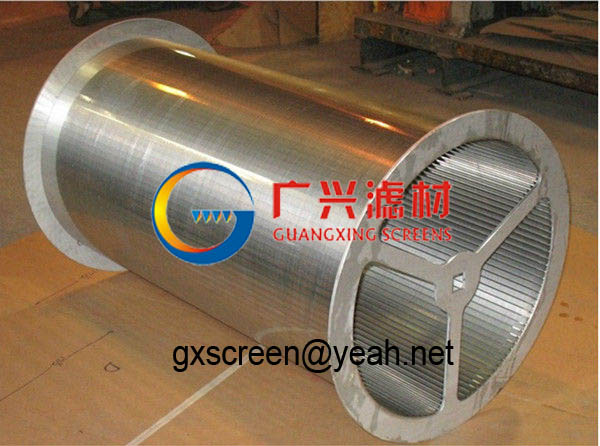

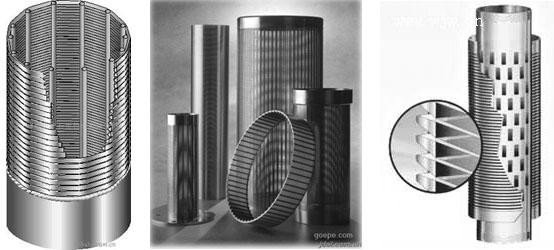

stainless steel muni-pak screen

December 6, 2017

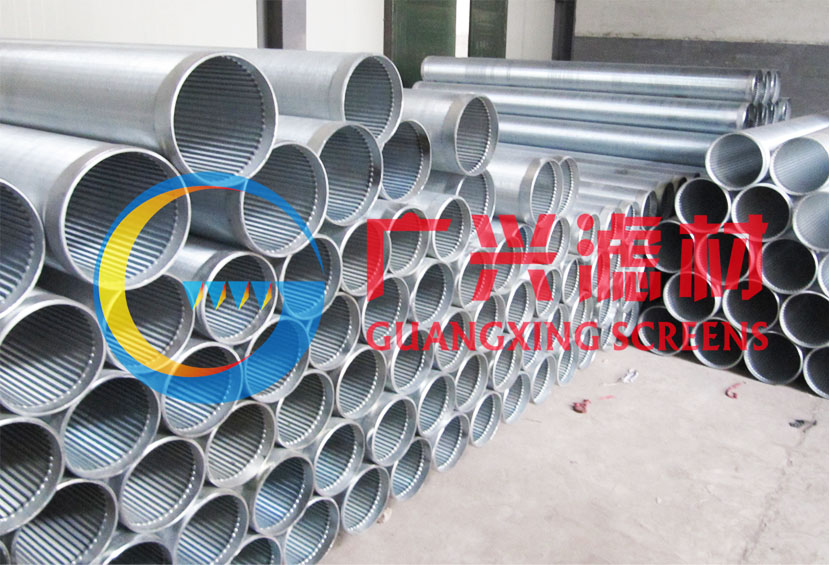

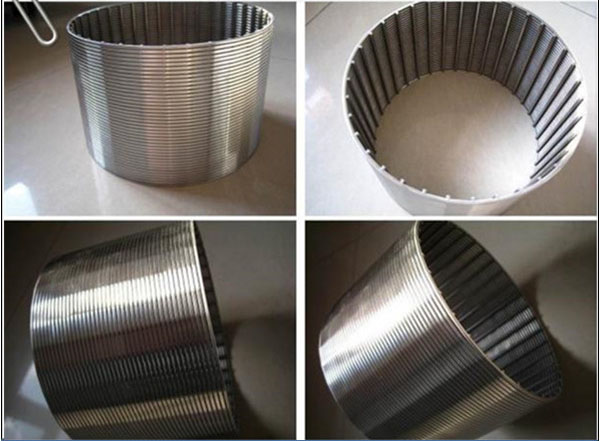

Stainless Steel Johnson wedge wire screen Filter

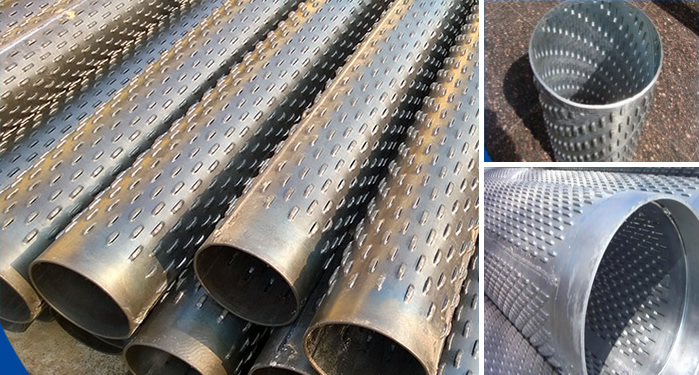

December 8, 2017Intake screens are subject to fouling or plugging by aquatic vegetation, which can include zebra mussels. Guangxing offers a copper-nickel alloy or a variety of non-toxic coatings to aid in minimizing the problem and allow for easy removal by physical scrubbing or high pressure cleaning.In addition, a chemical injection system may be speciffed to disperse an approved biocide into the screen body to control aquatic life that has passed through the screen area. These systems are carefully designed to ensure toxic chemicals are not released into the natural water source.

Installing an intake screen at the correct depth, distance from the shoreline and optimum distance from each other is a crucial step in maintaining the screens effiency for example; locating the screens away from the shoreline, distant from high concentrations of debris and marine life will reduce fouling of the screen, improve the water quality and operating period under full flow. However, where this is not possible, cleaning can be performed more frequently

Intake Screens can be installed in a variety of different patterns, such as the Vertical Slide Rail installation depicted here. Lifting mechanisms are employed with slide rails for convenient removal and maintenance of screens. Cone ends are depicted, facing upstream, allowing the natural current flow of water to sweep any debris from the intake screen. One of the intake screens is being hoisted for cleaning and evaluation. During service, the flow through the embedded pipeline connected to the intake screen in service is temporarily cut off. Interruption of flow to the facility will NOT occur. The remaining inline screen can handle the full flow requirement of the facility, allowing one screen to be removed. Additionally, a lifting mechanism may avoid having a diver go down and clean the screens. Many installations involve the pipeline and intake screen being welded together, making a more permanent application.

Intake Screen Options

Chemical Burst: Allows delivery of chemicals to the inside of the screen. Bursting chemicals will assist in the removal of impeding organisms adhering to the screen.

Exotic Alloys: To protect against screen binding organisms (such as Zebra Mussels). Also appropriate in corrosive environment applications such as salt water.

Internal Distribution Plates: To provide even flow patterns across the intake screen surface.

Guide Brackets: For rail type installation and service structures.

Diver Door: Provides access for manual servicing of intake screens.

Wedgewire Cap Ends: To further increase screening area where water is stagnant.

Drum-style screens are ideal for use when the water current passing the screen is very low (such as in quiet waters, lakes and reservoirs), for low water withdrawals, and in tight spaces. These screens are mounted with the flat or curved surface on the top to prevent debris from collecting on the screened surface.

DRUM INTAKE SCREENS

| Model No. | Capacity Range GPM | Nom Diameter “A” | Unit length “B” | App. Weight (LBS) |

| D-12 | 75-395 | 12″ | 13″ | 45 |

| D-18 | 225-910 | 18″ | 20″ | 125 |

| D-24 | 440-1550 | 24″ | 25″ | 230 |

| D-30 | 675-2275 | 30″ | 31″ | 350 |

| D-33 | 850-3300 | 33″ | 35″ | 400 |

| D-36 | 1000-3600 | 36″ | 37″ | 525 |

| D-42 | 1250-7750 | 42″ | 52″ | 675 |

| D-48 | 2000-6300 | 48″ | 60″ | 835 |

| D-54 | 2300-7850 | 54″ | 67″ | 1050 |

| D-60 | 3000-9750 | 60″ | 75″ | 1365 |

| D-66 | 3800-11750 | 66″ | 81″ | 1675 |

| D-72 | 4500-14000 | 72″ | 88″ | 2000 |

| D-78 | 5500-17000 | 78″ | 97″ | 2450 |

| D-84 | 6250-19000 | 84″ | 105″ | 3000 |

| Custom Drum Screens are available for higher capacities. | ||||

TEE INTAKE SCREENS

| Model No. | Capacity Range GPM | Nom Diameter “A” | Unit length “B” | App. Weight (LBS) |

| T-12 | 155-900 | 12″ | 45″ | 145 |

| T-16 | 275-1400 | 16″ | 55″ | 240 |

| T-18 | 500-2000 | 18″ | 62″ | 355 |

| T-20 | 625-2450 | 20″ | 66″ | 530 |

| T-24 | 850-3300 | 24″ | 80″ | 675 |

| T-28 | 1150-4000 | 28″ | 90″ | 875 |

| T-30 | 1400-4800 | 30″ | 98″ | 1250 |

| T-34 | 1700-5900 | 34″ | 106″ | 1500 |

| T-38 | 2000-7000 | 38″ | 116″ | 1800 |

| T-42 | 2500-9500 | 42″ | 150″ | 2200 |

| T-48 | 3700-12500 | 48″ | 170″ | 2800 |

| T-54 | 4500-15800 | 54″ | 190″ | 3950 |

| T-60 | 6000-19500 | 60″ | 215″ | 5400 |

| Custom Tee Screens are available for higher capacities. | ||||

Features of Intake Screens and Drum Intake Screens

Reliable water delivery

Reduced civil work requirement

Simple intake and pump station design

No debris handling/ disposal issues

Low maintenance cost

Environmentally fish friendly

Bio-fouling stays off the screen