September 16, 2017

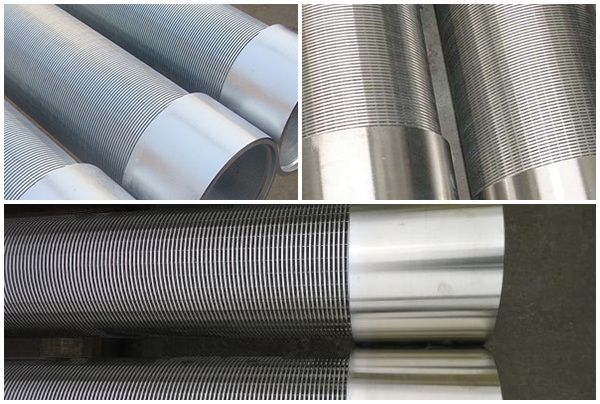

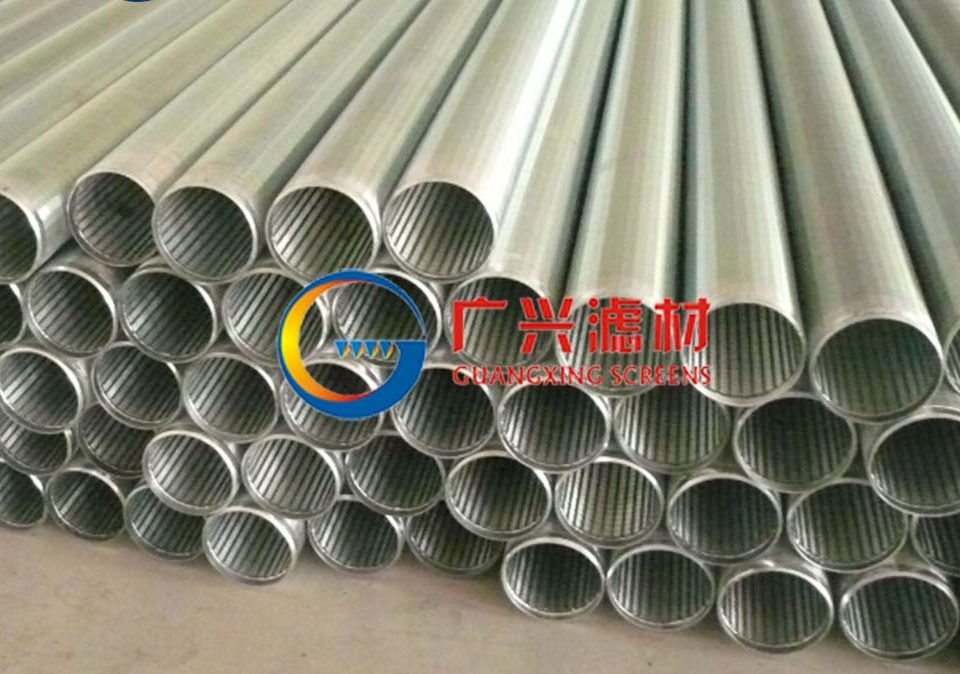

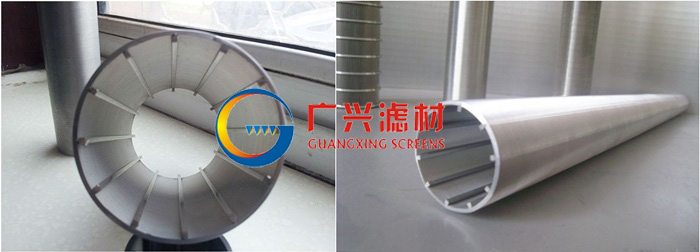

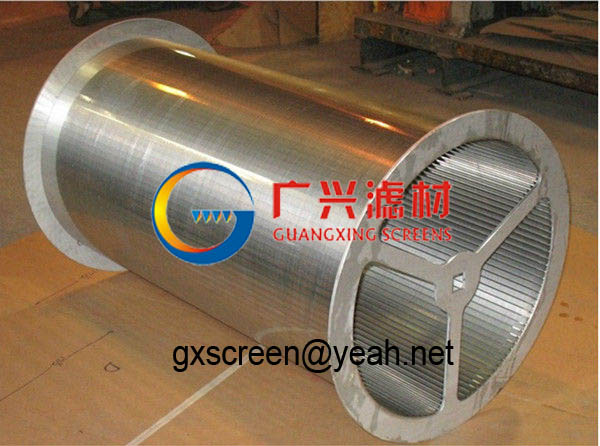

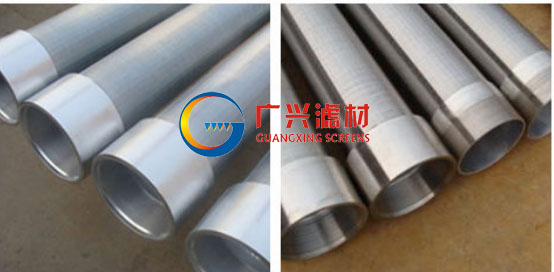

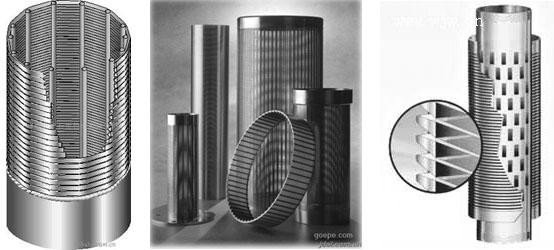

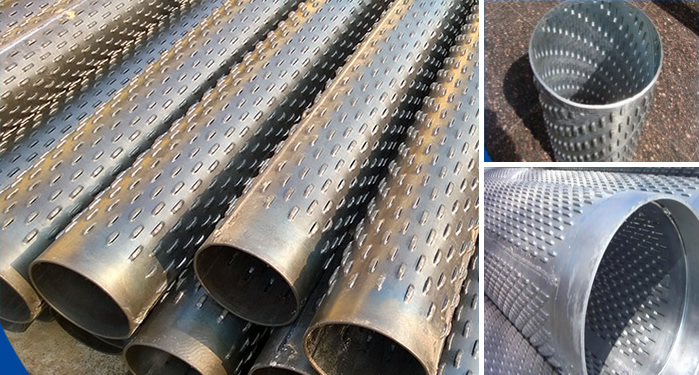

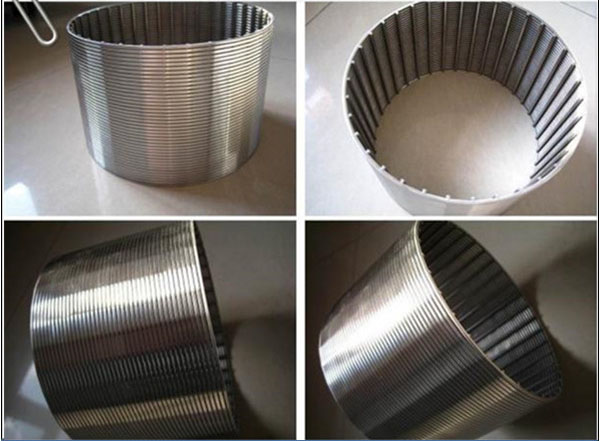

Advantages for Stainless Steel Johnson Well Screenfor drilling equipment: 1.Johnson screen has a continuous slot opening which significantly increases the available open area , thus providing greater access to the water bearing zone(the aquifer) 2.A V-shaped profile wire which avoids […]